swebster

Filing Flight Plan

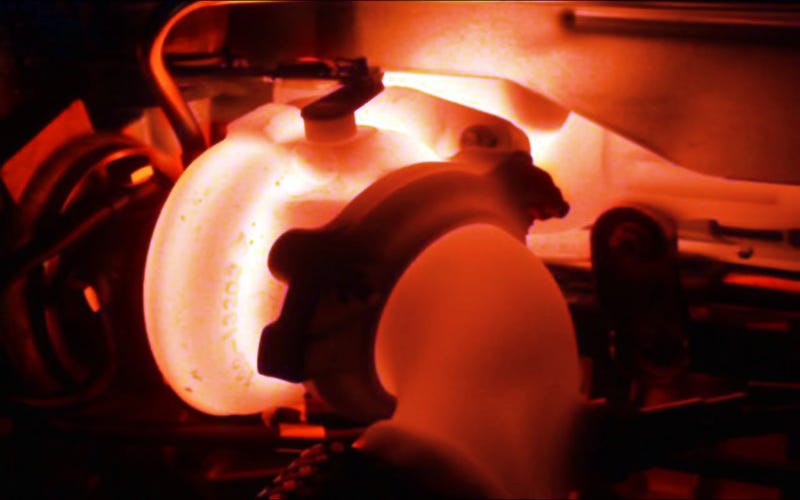

I have a 2002 Turbo 182T. If you have flown one of these you will be familiar with the incredible heat thrown off by the turbo charger. After flying for an hour you can quite literally fry an egg on the top of the cowl cover. The heat also contributes greatly to the hot start problems with the TIO540 engine. You HAVE to "flood start" it when the engine is hot or you will end up killing your starting motor and the thing will never light when hot.

So, in my quest to alleviate this problem, I have been searching for a Turbo blanket to wrap the turbo with which will help to contain the heat. Lycoming does offer one but its stupidly expensive (north of $2000). Aircraft Spruce offers a turbo blanket kit:

https://www.aircraftspruce.com/catalog/eppages/turbokit.php

Anyone have any experience with this product and can offer any comments positive or negative on it? I don't want to go installing something like this without some feedback from others who have been there before. I'm not keen on in-flight fires, so some input from someone who may have used this thing would be much appreciated.

Thanks

So, in my quest to alleviate this problem, I have been searching for a Turbo blanket to wrap the turbo with which will help to contain the heat. Lycoming does offer one but its stupidly expensive (north of $2000). Aircraft Spruce offers a turbo blanket kit:

https://www.aircraftspruce.com/catalog/eppages/turbokit.php

Anyone have any experience with this product and can offer any comments positive or negative on it? I don't want to go installing something like this without some feedback from others who have been there before. I'm not keen on in-flight fires, so some input from someone who may have used this thing would be much appreciated.

Thanks