jesse

Touchdown! Greaser!

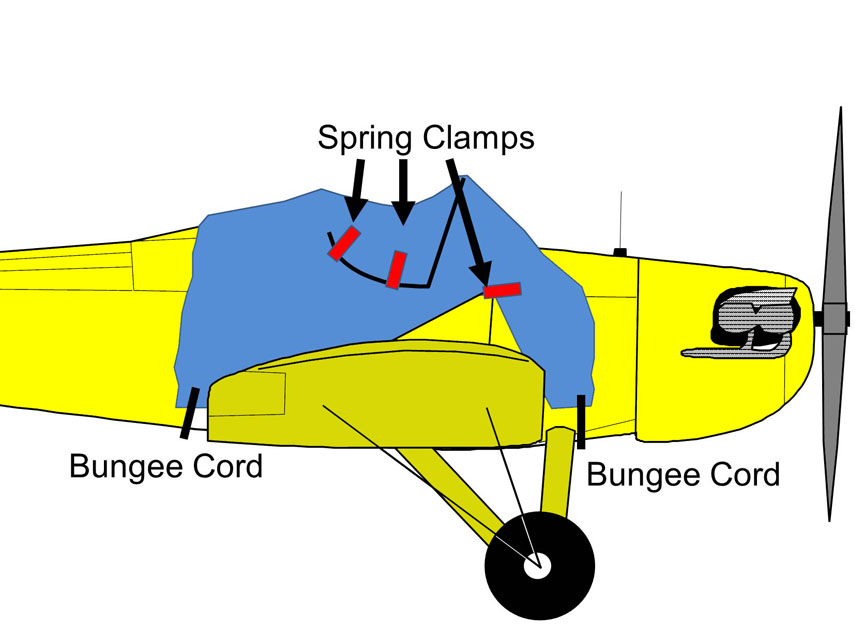

So Airventure is coming up, and I need to figure out a good way to cover the cockpit so that rain doesn't get in there. I also want something that can withstand the associated winds that come with the thunderstorms there. It would suck to have it blow off.

I need to figure this out this weekend. One challenge is that the landing wires make it so you can't just wrap a tarp around it. I've thought about trying to cut a tarp to fit and then secure with bungee cords but suspect it wouldn't hold up and would just rip after I cut it.

Ideally I think the cover would go over the windshield towards the gas cap and end somewhere around the end of the turtle neck or a few inches past.

Thoughts?

I need to figure this out this weekend. One challenge is that the landing wires make it so you can't just wrap a tarp around it. I've thought about trying to cut a tarp to fit and then secure with bungee cords but suspect it wouldn't hold up and would just rip after I cut it.

Ideally I think the cover would go over the windshield towards the gas cap and end somewhere around the end of the turtle neck or a few inches past.

Thoughts?