You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Multi viscosity or straight weight oil?

- Thread starter Fransisco

- Start date

Neal Howard

Cleared for Takeoff

Phillips 20-50 with Camguard works for me.

Dan Thomas

Touchdown! Greaser!

- Joined

- Jun 16, 2008

- Messages

- 10,823

- Display Name

Display name:

Dan Thomas

I used straight in the Gopher engine because that's what Lycoming said to put in it and my research showed there wasn't any real advantage the the multiweight in my situation. Ran 80 in the winter and 100 in the summer. I changed the oil more as there was no filter.

The official word from Lycoming on oil recommendations:

http://www.lycoming.com/Portals/0/t...-22-1995)/Lubricating Oil Recommendations.pdf

Note the date on this document: May 1995. More than 20 years ago, and they have been recommending multigrades for almost all engines for "all temperature," as they put it, or straight weights of various viscosities for more restrictive temperature ranges. Lycoming are the people that get to pay for warrantable failures on their new or overhauled engines, and if they found that multigrades had disadvantages at any ambient temperature they would have revised this document long ago. The fact that it's still currrent after 20 years tells me that multigrades are completely satisfactory and there is no reputable evidence that they cause corrosion or anything else. The other idea that straight-weights stick better and protect the parts I also have trouble believing, because that straight-weight is really runny when that hot engine shuts down and isn't going to be inclined to stick to anything for long. A multigrade whose viscosity doesn't drop so much with heat is more likely to resist runoff than the straight-weight.

Lycoming hasn't offered any warranty assistance on the Gopher engine since the sixties.

They pretty much disavowed all knowledge that there ever was a 435 built.

They pretty much disavowed all knowledge that there ever was a 435 built.

Fransisco

Filing Flight Plan

- Joined

- Nov 12, 2015

- Messages

- 21

- Location

- Knoxville , Tn

- Display Name

Display name:

Francisco McClain

The official word from Lycoming on oil recommendations:

http://www.lycoming.com/Portals/0/t...-22-1995)/Lubricating Oil Recommendations.pdf

Note the date on this document: May 1995. More than 20 years ago, and they have been recommending multigrades for almost all engines for "all temperature," as they put it, or straight weights of various viscosities for more restrictive temperature ranges. Lycoming are the people that get to pay for warrantable failures on their new or overhauled engines, and if they found that multigrades had disadvantages at any ambient temperature they would have revised this document long ago. The fact that it's still currrent after 20 years tells me that multigrades are completely satisfactory and there is no reputable evidence that they cause corrosion or anything else. The other idea that straight-weights stick better and protect the parts I also have trouble believing, because that straight-weight is really runny when that hot engine shuts down and isn't going to be inclined to stick to anything for long. A multigrade whose viscosity doesn't drop so much with heat is more likely to resist runoff than the straight-weight.

Very good info , I just didn't know where to find !!:wink2:

Fransisco

Filing Flight Plan

- Joined

- Nov 12, 2015

- Messages

- 21

- Location

- Knoxville , Tn

- Display Name

Display name:

Francisco McClain

I use Aeroshell 15W50 in my old A-65 and find that the oil temps stay a lot cooler with it than they do with any straight-weight, which tells me that the friction, and therefore the wear, is less.

A multigrade doesn't thicken as much when cold, so the pump finds it much easier to get it to the important bits when the engine is started. Bearings especially don't appreciate waiting for it.

In the flight school's airplanes I used 15W50 year-round and those engines all reached TBO without any hiccups and were still really tight when removed. Compressions in the high 70s and max oil pressures.

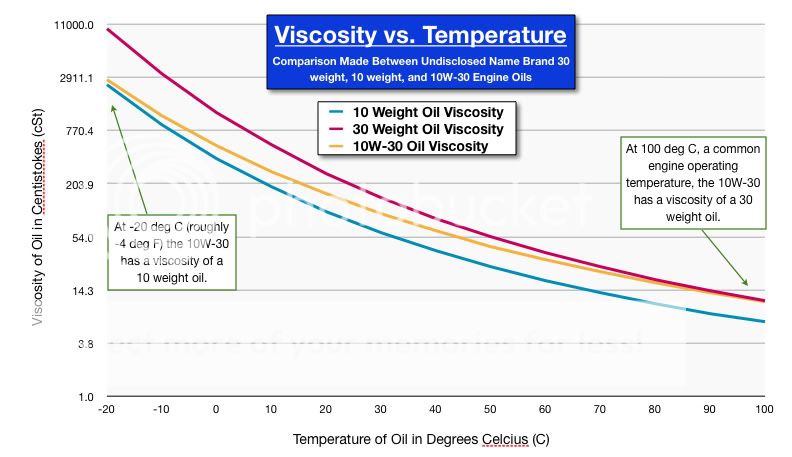

Multigrades aren't a mix of two straight-weights. A 15W50 is an SAE 15 oil with viscosity modifiers that clump together when their temperature rises and increase the effective viscosity of the oil, which means that they reduce the rate of viscosity decrease as the temp rises. A 15W50 will have the vicosity of a cold SAE 15 when cold and the viscosity of a hot SAE 50 when hot. I have shown students the differences between the various grades of hot and cold oils by leaving samples in the freezer overnight and immersing others in hot water for awhile. When pouring them, the viscosity changes are startling. A W100 will hardly move at -10°C, and your oil pump would have a hard time sucking it up from the sump. A W80 runs like water at 200°C. A multigrade displays a far narrower range of viscosity change.

Some folks resist this technology. It's too new or something? But we use computers to complain about it...

Very informative !!

- Joined

- Dec 29, 2015

- Messages

- 9,306

- Display Name

Display name:

Aztec Flyer

I fly in a wide range of ambient temps and use Aeroshell 15-50 year round.

Lycoming requires the use of an anti-scuff additive (Lycoming P/N LW-16702) in some of their engine models, including the IO-540s on my plane. Aeroshell and some other brands (but not all) have the additive so it makes it easier to maintain the correct concentration, especially when topping up between oil changes.

Lycoming requires the use of an anti-scuff additive (Lycoming P/N LW-16702) in some of their engine models, including the IO-540s on my plane. Aeroshell and some other brands (but not all) have the additive so it makes it easier to maintain the correct concentration, especially when topping up between oil changes.

Fearless Tower

Touchdown! Greaser!

I'm no oil expert, but that I've read that in several places and I can only speak from my personal experience here in coastal Virginia which does seem to validate that the engine with multi-weight is more susceptible to corrosion when sitting than when using straight weight.The other idea that straight-weights stick better and protect the parts I also have trouble believing, because that straight-weight is really runny when that hot engine shuts down and isn't going to be inclined to stick to anything for long. A multigrade whose viscosity doesn't drop so much with heat is more likely to resist runoff than the straight-weight.

I fly in a wide range of ambient temps and use Aeroshell 15-50 year round.

Lycoming requires the use of an anti-scuff additive (Lycoming P/N LW-16702) in some of their engine models, including the IO-540s on my plane. Aeroshell and some other brands (but not all) have the additive so it makes it easier to maintain the correct concentration, especially when topping up between oil changes.

First post.....

Welcome to POA....

- Joined

- Dec 29, 2015

- Messages

- 9,306

- Display Name

Display name:

Aztec Flyer

First post.....

Welcome to POA....

Many thanks! I've been lurking for a while and sure appreciate the incredible range of experience and information being exchanged here.

Avoiding expensive mistakes by drawing on the knowledge of others is one of the most effective ways I keep down the cost of this flying obsession.

Many thanks! I've been lurking for a while and sure appreciate the incredible range of experience and information being exchanged here.

Avoiding expensive mistakes by drawing on the knowledge of others is one of the most effective ways I keep down the cost of this flying obsession.

We prefer to call it a terminal disease...

Once you are addicted to aviation, it is a life long habit...

Once you are addicted to aviation, it is a life long habit...chemgeek

En-Route

- Joined

- Dec 5, 2009

- Messages

- 2,978

- Display Name

Display name:

chemgeek

Here in the NE it's too much of a hassle to change oil weights every season and the transitional seasons are quite variable, maybe 30s in the am and 70s in the pm. I'm using 20W50 Exxon elite which has the anticorrosion package similar to or identical to Camguard. In my previous engine I mostly used multiweight Aeroshell and it lived a long and happy life.

Aaronk25

Pre-takeoff checklist

- Joined

- Nov 3, 2013

- Messages

- 154

- Display Name

Display name:

Aaronk25

Here in the NE it's too much of a hassle to change oil weights every season and the transitional seasons are quite variable, maybe 30s in the am and 70s in the pm. I'm using 20W50 Exxon elite which has the anticorrosion package similar to or identical to Camguard. In my previous engine I mostly used multiweight Aeroshell and it lived a long and happy life.

The additive package in Exxon Elite is very small in comparison to camguard. If you email Ed Collins, technical director of cam guard he can tell you the difference but it was somthing like pennies of additive per at vs $1 per qt cost difference.

But if your having luck with what your doing no reason to change, right?

Sent from my iPhone using Tapatalk

Stewartb

Final Approach

Aeroshell 15-50 is my last choice with Exxon Elite coming in a close 2nd to last. Semi-synthetic engine oils do not provide any benefit for my 25 hour change cycle. They cost more, promote more blow-by, and promote oil seeps that aren't there otherwise. I once had a slipping starter clutch and asked Ben Visser (long time Aeroshell engineer and spokesman) about it after a Lake Hood meeting where he gave a presentation. He told me to lose the semi-syn and switch to straight weight Aeroshell or 20-50 Phillips. When I did the blow-by was reduced (800TTSN engine) and that was evident by reduced breather drips and reduced darkening of the oil. Leaks dried up. The starter clutch never needed attention. I've never looked back. I, too, have quizzed Ed Kollin about many things to do with oil in airplanes from adding MMO or STP to various other myths like straight weight "clinging" better. The best tidbit he ever told me was what he uses in his own airplane. Phillips X/C 20-50 with 5% Camguard.

Bottom line? Engine manufacturers recommend different viscosities for different ambient temperatures. They don't offer any TBO advantage or warranty extension for using straight weight or multi-vis, semi-syn or mineral. Use the oil you believe is best for you and accept that other users are entitled to do the same.

Bottom line? Engine manufacturers recommend different viscosities for different ambient temperatures. They don't offer any TBO advantage or warranty extension for using straight weight or multi-vis, semi-syn or mineral. Use the oil you believe is best for you and accept that other users are entitled to do the same.

Last edited: