Lycoming O-235 L2C. Currently has about 350 hrs and 7 years SMOH by a Major shop.

It began with slightly elevated aluminum in the oil sample. Then iron went up a little too. Oil analysis folks felt there was no reason for concern. Yet. Compressions have been good and power and oil consumption were normal. Baffles were tight and temps were fine.

A few tiny flakes of AL were found in the screen. It appears the number and duration of flights decreased about this time. At the last filter pull the jugs were scoped. #3 had a slight marking in the Piston Pin range. Although it would have been “ Lycoming Legal “ to fly the decision was made to pull #3. Another Piston Pin Plug issue was expected.

The Plugs ( end caps) appear to be fine as the dark ring indicates normal wear to me.

With the cylinder off the marking is almost indistinguishable and cannot be felt. So what is the source?

The Piston Pin did not want to move in the Piston. In the removal process one of the Plugs was scratched. Some scoring was noted on the Piston and Jug about 90 degrees from the Pin travel range. We believe this to be the source of the metal. The marking on the cylinder can only be felt in one spot. So what happened here?

The owner mentioned he had a Spark Plug issue some time ago. A chunk of the Insulator of the REM37BY plug had broken off in #4 cylinder. It was never found. The Spark Plug was replaced and everything seemed fine. Back to current and he thinks that when the AL issues started. I have seen Exhaust Valves break and pieces found in another cylinder. Did the ceramic also “ Migrate” and then gouge #3?

My first try at attaching pix so I hope it works. There are some poor quality pix of the components.

Comments invited on:

Cylinder / Piston scoring

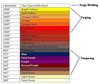

Blue Piston Pin

Pin tight in Piston

Deposits of side of piston

Comment on suggested path forward also.

Hmm. Doesn’t seem to load pix. I’ll post this and try again.

It began with slightly elevated aluminum in the oil sample. Then iron went up a little too. Oil analysis folks felt there was no reason for concern. Yet. Compressions have been good and power and oil consumption were normal. Baffles were tight and temps were fine.

A few tiny flakes of AL were found in the screen. It appears the number and duration of flights decreased about this time. At the last filter pull the jugs were scoped. #3 had a slight marking in the Piston Pin range. Although it would have been “ Lycoming Legal “ to fly the decision was made to pull #3. Another Piston Pin Plug issue was expected.

The Plugs ( end caps) appear to be fine as the dark ring indicates normal wear to me.

With the cylinder off the marking is almost indistinguishable and cannot be felt. So what is the source?

The Piston Pin did not want to move in the Piston. In the removal process one of the Plugs was scratched. Some scoring was noted on the Piston and Jug about 90 degrees from the Pin travel range. We believe this to be the source of the metal. The marking on the cylinder can only be felt in one spot. So what happened here?

The owner mentioned he had a Spark Plug issue some time ago. A chunk of the Insulator of the REM37BY plug had broken off in #4 cylinder. It was never found. The Spark Plug was replaced and everything seemed fine. Back to current and he thinks that when the AL issues started. I have seen Exhaust Valves break and pieces found in another cylinder. Did the ceramic also “ Migrate” and then gouge #3?

My first try at attaching pix so I hope it works. There are some poor quality pix of the components.

Comments invited on:

Cylinder / Piston scoring

Blue Piston Pin

Pin tight in Piston

Deposits of side of piston

Comment on suggested path forward also.

Hmm. Doesn’t seem to load pix. I’ll post this and try again.