AeroLudite

Pre-takeoff checklist

- Joined

- May 25, 2020

- Messages

- 113

- Display Name

Display name:

AeroLudite

Ever since my previous annual in ‘22, my plane has a “vibration”. That’s obviously related to the prop.

At the annual, the prop was removed for the crank shaft AD inspection. Previously the plane was remarkably smooth running. Now, NOT.

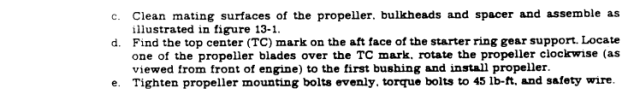

PREVIOUSLY, the prop would stop at the 10 o’clock position as viewed from in front of the plane. Now, it stops at the 2 o’clock position. My mechanic IA is adamant that this is correct. However, at a 100hr inspection, another mechanic at my request reinstalled it to stop at 10 o’clock. It ran smoother, again. But, at most recent annual the prop was reinstalled to stop at 2 o’clock and vibration returned. It’s enough that’s it’s loosening interior screws!

Which is correct?

At the annual, the prop was removed for the crank shaft AD inspection. Previously the plane was remarkably smooth running. Now, NOT.

PREVIOUSLY, the prop would stop at the 10 o’clock position as viewed from in front of the plane. Now, it stops at the 2 o’clock position. My mechanic IA is adamant that this is correct. However, at a 100hr inspection, another mechanic at my request reinstalled it to stop at 10 o’clock. It ran smoother, again. But, at most recent annual the prop was reinstalled to stop at 2 o’clock and vibration returned. It’s enough that’s it’s loosening interior screws!

Which is correct?