Ed Haywood

En-Route

IMO you have it backwards.I've never cut a filter, but do oil analysis on every oil change.

IMO you have it backwards.I've never cut a filter, but do oil analysis on every oil change.

Appendix D to Part 43—Scope and Detail of Items (as Applicable to the Particular Aircraft) To Be Included in Annual and 100-Hour Inspections

(d) Each person performing an annual or 100-hour inspection shall inspect (where applicable) components of the engine and nacelle group as follows:

(3) Internal engine—for cylinder compression and for metal particles or foreign matter on screens and sump drain plugs. If there is weak cylinder compression, for improper internal condition and improper internal tolerances.

What engine was that from? Did you have any other indications? If it was the cam lobes, was the engine making static RPM?

Thanks for the reply. One thing is, if you are using Phillips Victory, I do not believe you need to add CamGuard. It already has the Lycoming anti wear, scuff additive in it. The non-Victory does not have it. I used to use that with CamGuard before switching over.This was from a Lycoming O-360 C1F in a Maule MX7. I had been doing regular oil analysis with Blackstone and all was looking good until I found metal. Once I found metal, I stopped doing additional oil analysis since the damage was so obvious. The engine still makes static RPM, it has full oil pressure and seems to perform well. I'm sure it is down on power, but the power loss has been gradual, so I haven't noticed it from flight to flight. Getting all the bower back (and then some) with a rebuilt engine that has been flowed and ported will be fun. After a 6 month wait, my rebuilt engine from LyCon will be ready later this month. The engine had 2400 hours on the tach, so I have nothing to complain about. I had been using CAMGUARD with Phillips Victory 20W/50 oil.

I don't use CamGuard, but worth noting it is not an anti-wear/scuff additive. It is an anti-corrosion additive.Thanks for the reply. One thing is, if you are using Phillips Victory, I do not believe you need to add CamGuard. It already has the Lycoming anti wear, scuff additive in it. The non-Victory does not have it. I used to use that with CamGuard before switching over.

Victory AW 20W-50 is pre-blended with the proper concentration of anti-scuff/anti-wear additive (LW-16702) mandated by Lycoming Service Bulletins 446E and 471B and Service Instruction 1409C.

Good point. I stand corrected. Two different additives.I don't use CamGuard, but worth noting it is not an anti-wear/scuff additive. It is an anti-corrosion additive.

I don't use CamGuard, but worth noting it is not an anti-wear/scuff additive. It is an anti-corrosion additive.

aslcamguard.com

aslcamguard.com

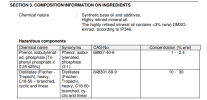

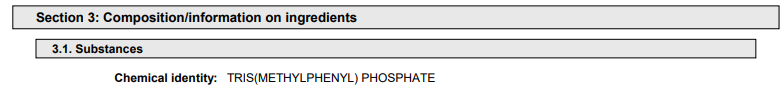

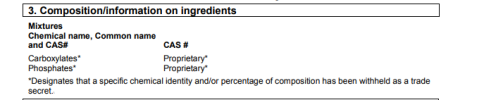

From the Aeroshell 15W50 MSDS:Camguard's website claims it is an antiwear additive.

Engine Oil Anti Wear Additive Oklahoma | Camguard

Boost your engine's protection in Oklahoma with Camguard's Engine Oil Anti Wear Additive. Experience enhanced performance and durability.aslcamguard.com

That said, Camguard is not the same as what is in the Aeroshell plus oils and the Phillips Victory oils. A lot of people seem convinced it is, but there is plenty of evidence to the contrary out there, if people look for it.