James331

Ejection Handle Pulled

- Joined

- Apr 18, 2014

- Messages

- 20,309

- Display Name

Display name:

James331

hey guys,

I'm looking at what I need to buy/read/do for my little 18' speed boat, so far planning on a soda blast and re gelcoat, looking todo it myself

Can I use normal pearl (house of kolors) in the gel coat?

What's the process for doing it? I don't have any gel coat experience, but I have every other week off and I'm looking to hit this thing like a 9-5.

Looking for white bottom paint (along the upper chime), transom and a thin racing stripe, red top and sides, quasi donzi style.

What am I looking at process and equipment wise.

(Yes I'll shave the draggy nav light off and reupholster lol)

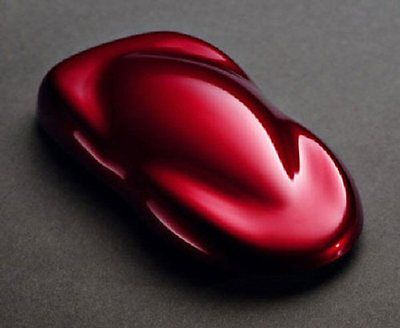

House Of Kolor S2-KBC01 Shimirin 2 Candy Brandywine

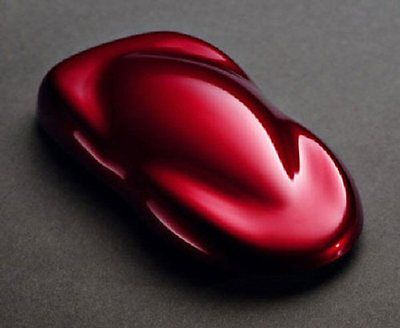

DP35 Deep Blue Dry Pearl

I'm looking at what I need to buy/read/do for my little 18' speed boat, so far planning on a soda blast and re gelcoat, looking todo it myself

Can I use normal pearl (house of kolors) in the gel coat?

What's the process for doing it? I don't have any gel coat experience, but I have every other week off and I'm looking to hit this thing like a 9-5.

Looking for white bottom paint (along the upper chime), transom and a thin racing stripe, red top and sides, quasi donzi style.

What am I looking at process and equipment wise.

(Yes I'll shave the draggy nav light off and reupholster lol)

House Of Kolor S2-KBC01 Shimirin 2 Candy Brandywine

DP35 Deep Blue Dry Pearl

Last edited: