Jon Wilder

Pre-takeoff checklist

- Joined

- Oct 19, 2015

- Messages

- 183

- Display Name

Display name:

Jwylde

Hi all.

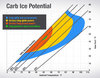

We have a PFD/MFD Garmin G3X Touch system with Garmin GEA 24 engine analyzer installed. We're seeing carb temps about 20°+ greater than OAT all the time. On the ground without the engine running, it reads ambient temp along with the CHT and EGT senders (within a few degrees of them I'd say).

In our minds, we're thinking carb temp should always be LOWER than OAT due to venturi effect. But this does not seem to be the case.

Anyone else out there running a similar setup? What are your carb temps relative to OAT?

Thanks in advance.

We have a PFD/MFD Garmin G3X Touch system with Garmin GEA 24 engine analyzer installed. We're seeing carb temps about 20°+ greater than OAT all the time. On the ground without the engine running, it reads ambient temp along with the CHT and EGT senders (within a few degrees of them I'd say).

In our minds, we're thinking carb temp should always be LOWER than OAT due to venturi effect. But this does not seem to be the case.

Anyone else out there running a similar setup? What are your carb temps relative to OAT?

Thanks in advance.