- Joined

- May 24, 2016

- Messages

- 848

- Display Name

Display name:

4RNB

C172M with new engine, likely approaching 50 hours on it and not needing much oil (1 quart). Perhaps I can stop running the engine hard? Before engine monitor and new engine, my leaning process was to set RPM as desired, then pull mixture back until engine runs a little rough or I see RPM drop, then twist the mixture 2-3 times. When I do this with current set up I see GPM <8 but CHTs go above 400, not 420 though, and EGTs get higher. Yellow warning for CHTs programmed at 400, lycoming redline is 500. Mike Busch would suggest >400 is tough on cylinder longevity and EGTs can be taken more lightly. I end up having to enrich the mixture back near 10 GPM to get CHTs back below 400.

So, If you fly an Airplains 180 HP with engine monitoring, I'd love to hear your figures and processes.

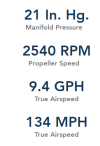

It looks like Airplains says 9.4GPM, see image.

Of note, I still need to get my Airbox baffle installed, hoping this will improve cooling. https://www.pilotsofamerica.com/community/threads/engine-air-intake.142634/#post-3424311

Thanks for any contribution

So, If you fly an Airplains 180 HP with engine monitoring, I'd love to hear your figures and processes.

It looks like Airplains says 9.4GPM, see image.

Of note, I still need to get my Airbox baffle installed, hoping this will improve cooling. https://www.pilotsofamerica.com/community/threads/engine-air-intake.142634/#post-3424311

Thanks for any contribution