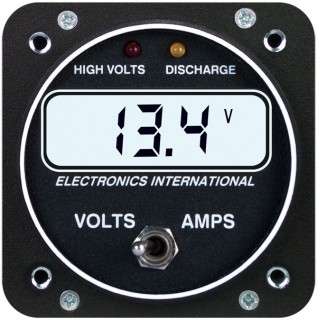

Started my '69 Cherokee 140 for a flight today. Nothing out of the ordinary for the 20 minute flight to pick up a friend. After starting again the ammeter was swinging like a clock pendulum from 0 to 60 to 0. I cycled the alternator a few times, shut off everything, cycled alternator and still no change. Cycled main power and still no change. Note that with the alternator off the ammeter goes to 0. The rate of the swing was RPM related; low RPM slow rate, high RPM high rate.

I shut everything down and let it sit while I pondered the electrical diagram and my own experience with electrical systems. After about 20 minutes I started it for the short flight back to my home base airport. The ammeter read steady and showed typical current readings when the alternator was loaded. It worked perfectly for the 20 minute flight.

Electronic problems that are intermittent are always hard to troubleshoot compared to hard failures. I "assume" the voltage regulator is the original 1969 mechanical voltage regulator. My armchair diagnosis is the voltage regulator allowed the alternator to go over voltage and the over voltage protection relay kicked in shutting the alternator down. Then the voltage dropped and the alternator output climbed and the over voltage relay kicked in and the cycle continued.

As to what resolved it in the 20 minutes it was shutdown I can only attribute to temperature compensation that is present in the mechanical voltage regulator or a stuck field contact that cooled off and unstuck.

I don't want to wait until a hard failure to occur and want to address it now. Certainly I can relate the symptoms to my mechanic. If he can't diagnose the intermittent problem definitively I would have him replace the voltage regulator with a modern solid state unit and work our way to the alternator.

Anyone seen this problem before and if so what was the solution without shot gunning replacing parts?

Thanks,

I shut everything down and let it sit while I pondered the electrical diagram and my own experience with electrical systems. After about 20 minutes I started it for the short flight back to my home base airport. The ammeter read steady and showed typical current readings when the alternator was loaded. It worked perfectly for the 20 minute flight.

Electronic problems that are intermittent are always hard to troubleshoot compared to hard failures. I "assume" the voltage regulator is the original 1969 mechanical voltage regulator. My armchair diagnosis is the voltage regulator allowed the alternator to go over voltage and the over voltage protection relay kicked in shutting the alternator down. Then the voltage dropped and the alternator output climbed and the over voltage relay kicked in and the cycle continued.

As to what resolved it in the 20 minutes it was shutdown I can only attribute to temperature compensation that is present in the mechanical voltage regulator or a stuck field contact that cooled off and unstuck.

I don't want to wait until a hard failure to occur and want to address it now. Certainly I can relate the symptoms to my mechanic. If he can't diagnose the intermittent problem definitively I would have him replace the voltage regulator with a modern solid state unit and work our way to the alternator.

Anyone seen this problem before and if so what was the solution without shot gunning replacing parts?

Thanks,