WatchMeFly

Filing Flight Plan

- Joined

- Jul 21, 2023

- Messages

- 5

- Display Name

Display name:

5094Romeo

Hello Avaitors,

I just bought my first airplane and of course I'm being hazed into the avation community with problems from the get go )

)

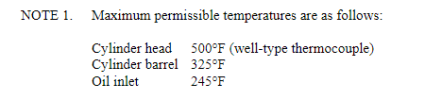

I have a 1974 172M with a freshly overhauled engine (currently about 12 hours). I understand that I am still in the break in period and temps are going to be a bit above normal but I am experiencing oil temps of up to 265deg crusing at 4500ft at 2400rpm. Even when I baby it, I can't keep the temps below 245. I have already replace all the baffeling, oil temp probe, and brand new oversized oil cooler. The plane came with Phillips X/C but I changed it to Aeroshell 100 mineral. Any ideas???? Right now my carb heat is inoperative and the hose has been removed. Can that affect air flow to the oil cooler in some way? Also, all the avonics are brand new (dynon skyview). Is it possible something is not callibrated properly and I am getting false readings?

I just bought my first airplane and of course I'm being hazed into the avation community with problems from the get go

I have a 1974 172M with a freshly overhauled engine (currently about 12 hours). I understand that I am still in the break in period and temps are going to be a bit above normal but I am experiencing oil temps of up to 265deg crusing at 4500ft at 2400rpm. Even when I baby it, I can't keep the temps below 245. I have already replace all the baffeling, oil temp probe, and brand new oversized oil cooler. The plane came with Phillips X/C but I changed it to Aeroshell 100 mineral. Any ideas???? Right now my carb heat is inoperative and the hose has been removed. Can that affect air flow to the oil cooler in some way? Also, all the avonics are brand new (dynon skyview). Is it possible something is not callibrated properly and I am getting false readings?