You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DuPuis Family Cobra Build

- Thread starter Ted

- Start date

Ted

The pilot formerly known as Twin Engine Ted

- Joined

- Oct 9, 2007

- Messages

- 29,892

- Display Name

Display name:

iFlyNothing

Well heck, that old crank ain't good for anything else!

If you look carefully, I actually used the good crank I have sitting around!

Ted

The pilot formerly known as Twin Engine Ted

- Joined

- Oct 9, 2007

- Messages

- 29,892

- Display Name

Display name:

iFlyNothing

A few pages ago I set a soft goal of being able to drive the car to the "Ford v Ferrari" opening night of 11/15. That would ideally be in a more or less complete form, although it would be acceptable to me if the bodywork wasn't completed and maybe some other details that require additional work. I think this goal is very attainable.

A further soft goal would be driving my son to his first day of school, obviously in a less complete form, maybe the "go kart" stage. He's helped to build it and I think that would be something that he'd remember and would really love. That's a softer goal that I'm less confident I can attain, but looking at the timeline, I actually can work out a plan that would get me to the go-kart phase.

I am essentially working on this car to some extent every evening and some on the weekends when my wife is at work (she works one week on, one week off). When she's home I'm spending time with her in the evenings and working on other household things on the weekends that are either "honey-dos" or projects that I need another adult around for like getting trees out of the ground with the dozer, as well as some research and parts ordering. The school district hasn't published the exact start date for my son's school yet, but based on last year it should be sometime in late August. That gives me roughly 5 working weeks (plus 5 off weeks = 10 weeks total) including this one I'm on now. So, let's look at that:

Week 1 (current): Complete rebuild of the rear axle and get installed in the car. This is pretty doable and I think I should be able to get it done or close to done.

Week 2: Run brake lines/hoses, install fuel tank and fuel lines. I'm missing a lot of parts needed for this still but in a good position

Week 3: Build engine, hook up to transmission, install in car. Big risk item here is having a short block. Everything else I should be able to get

Week 4: Run electrical system, work more on the details of the engine install such as radiator/coolant/etc. At this point the car should be in what's considered "go-kart" stage where I should be able to do first engine start

Week 5: Do a lot of riveting and get the seats at harnesses installed, other details

It's still tight and I'm not too hopeful that I'll actually make it, but it's within the realm of possibility. Part of my goal with this is to get it done, but not let it distract me from important family tasks and other things. Driving my son to his first day of 1st grade in the car would be great, but there will be other opportunities once it's completed to do that. Either way, if I can get close to achieving that timeline, that should make a mid-November "completion" date quite attainable. That would put me at 13-14 months from kit first arriving to completed.

A further soft goal would be driving my son to his first day of school, obviously in a less complete form, maybe the "go kart" stage. He's helped to build it and I think that would be something that he'd remember and would really love. That's a softer goal that I'm less confident I can attain, but looking at the timeline, I actually can work out a plan that would get me to the go-kart phase.

I am essentially working on this car to some extent every evening and some on the weekends when my wife is at work (she works one week on, one week off). When she's home I'm spending time with her in the evenings and working on other household things on the weekends that are either "honey-dos" or projects that I need another adult around for like getting trees out of the ground with the dozer, as well as some research and parts ordering. The school district hasn't published the exact start date for my son's school yet, but based on last year it should be sometime in late August. That gives me roughly 5 working weeks (plus 5 off weeks = 10 weeks total) including this one I'm on now. So, let's look at that:

Week 1 (current): Complete rebuild of the rear axle and get installed in the car. This is pretty doable and I think I should be able to get it done or close to done.

Week 2: Run brake lines/hoses, install fuel tank and fuel lines. I'm missing a lot of parts needed for this still but in a good position

Week 3: Build engine, hook up to transmission, install in car. Big risk item here is having a short block. Everything else I should be able to get

Week 4: Run electrical system, work more on the details of the engine install such as radiator/coolant/etc. At this point the car should be in what's considered "go-kart" stage where I should be able to do first engine start

Week 5: Do a lot of riveting and get the seats at harnesses installed, other details

It's still tight and I'm not too hopeful that I'll actually make it, but it's within the realm of possibility. Part of my goal with this is to get it done, but not let it distract me from important family tasks and other things. Driving my son to his first day of 1st grade in the car would be great, but there will be other opportunities once it's completed to do that. Either way, if I can get close to achieving that timeline, that should make a mid-November "completion" date quite attainable. That would put me at 13-14 months from kit first arriving to completed.

Ted

The pilot formerly known as Twin Engine Ted

- Joined

- Oct 9, 2007

- Messages

- 29,892

- Display Name

Display name:

iFlyNothing

Tonight I managed to get exactly what I intended to do done. I got the axle bearings and seals on, as well as the differential rebuilt.

The Ford Performance kit came with the shims, friction plates, and steel plates all pre-measured for the correct thickness and also in the correct order. Note that order isn't what was in the differential when I removed it, but it may be an updated methodology or a different order used for the Ford Performance kit. The friction plates had carbon fiber on them, which if it existed on the original plates (I don't think it did) it was gone.

As part of assembling a limited slip differential you're supposed to soak the friction plates in the friction modifier required for 15 minutes prior to install. I had ordered two bottles of friction modifier and it took both of them to be able to submerge all of the plates at once. I suppose I could've done one side at a time, but I didn't want to. You're supposed to discard the fluid after using it for soaking, so I will. The bottles of differential fluid I bought say they have the required friction additive in them already but I'm wondering if I shouldn't add the proper bottle just to make sure it has enough. Maybe some of the racers will know better than me.

I also got the new carrier bearings pressed on - convenient having a 20-ton press in the shop.

The one part I didn't complete was installation of the S-spring. That sits between the spider gears and provides a preload so that the clutches do their job and provide "limited slip". That shouldn't take long to do tomorrow.

Tomorrow I think the goal will be to put the ring gear on the differential and then also see if I can't get the pinion installed and set to the proper depth, or at least generally start on the process.

One thing is that I can say for sure the aftermarket gears were generic no-name and not proper Ford ones. The Ford Performance gears are clearly marked as such with the ratio. The ones that came off of it, no markings at all. I'll be happier having the correct kind in there.

I have a feeling that it'll end up taking two nights (or more) to get the ring and pinion installed correctly, and that assumes I don't need to get more shims or other parts. So hopefully I can get it in the car this weekend and "completed" but it also won't surprise me if I can't.

The new clutch pack setup installed. A different (and in my engineering opinion better) pattern than what was removed.

The illustration showing the updated pattern.

The friction disk with carbon fiber material on it.

Presto chango rebuilt differential!

The Ford Performance kit came with the shims, friction plates, and steel plates all pre-measured for the correct thickness and also in the correct order. Note that order isn't what was in the differential when I removed it, but it may be an updated methodology or a different order used for the Ford Performance kit. The friction plates had carbon fiber on them, which if it existed on the original plates (I don't think it did) it was gone.

As part of assembling a limited slip differential you're supposed to soak the friction plates in the friction modifier required for 15 minutes prior to install. I had ordered two bottles of friction modifier and it took both of them to be able to submerge all of the plates at once. I suppose I could've done one side at a time, but I didn't want to. You're supposed to discard the fluid after using it for soaking, so I will. The bottles of differential fluid I bought say they have the required friction additive in them already but I'm wondering if I shouldn't add the proper bottle just to make sure it has enough. Maybe some of the racers will know better than me.

I also got the new carrier bearings pressed on - convenient having a 20-ton press in the shop.

The one part I didn't complete was installation of the S-spring. That sits between the spider gears and provides a preload so that the clutches do their job and provide "limited slip". That shouldn't take long to do tomorrow.

Tomorrow I think the goal will be to put the ring gear on the differential and then also see if I can't get the pinion installed and set to the proper depth, or at least generally start on the process.

One thing is that I can say for sure the aftermarket gears were generic no-name and not proper Ford ones. The Ford Performance gears are clearly marked as such with the ratio. The ones that came off of it, no markings at all. I'll be happier having the correct kind in there.

I have a feeling that it'll end up taking two nights (or more) to get the ring and pinion installed correctly, and that assumes I don't need to get more shims or other parts. So hopefully I can get it in the car this weekend and "completed" but it also won't surprise me if I can't.

The new clutch pack setup installed. A different (and in my engineering opinion better) pattern than what was removed.

The illustration showing the updated pattern.

The friction disk with carbon fiber material on it.

Presto chango rebuilt differential!

SoonerAviator

Final Approach

- Joined

- Jul 21, 2014

- Messages

- 9,353

- Location

- Broken Arrow, OK

- Display Name

Display name:

SoonerAviator

I'd go ahead and add another bottle of Ford friction modifier. I did when I changed out my differential fluid in the truck a few years ago. It won't hurt anything to have a little extra in there, as the bottles are pretty small.

Ted

The pilot formerly known as Twin Engine Ted

- Joined

- Oct 9, 2007

- Messages

- 29,892

- Display Name

Display name:

iFlyNothing

I'd go ahead and add another bottle of Ford friction modifier. I did when I changed out my differential fluid in the truck a few years ago. It won't hurt anything to have a little extra in there, as the bottles are pretty small.

That was my thought as well. Thanks.

After I made my post update last night I read through the official Ford installation manual (what a concept!). Ford recommends some LocTite put on the ring before I install it on the differential. So, I need to pick up some of that at lunch to prepare me for this evening's install. After looking at the specs on the drag you're supposed to have, I know this was assembled way too loose before. I suspected that and it's been confirmed now. The one thing I'm wondering about is whether I'll need new/more shims for the differential and the pinion. If I do that may delay the final install, but otherwise I should be good to go and can get all the other items completed relating to the axle.

One thing that I didn't do, though, was measure the runout of the ring before removing the whole setup. That has me a hair concerned since it's a small amount of runout allowed (0.003") and if you exceed that the whole rear axle is scrap. That is a bit concerning to me given everything else I've found/taken out of this car, but rear axles are pretty tough and this thing didn't make a ton of power. So we'll just have to see. For now I'll proceed assuming the axle itself is good.

455 Bravo Uniform

Final Approach

One differing opinion on the additive from a chemical perspective - they’ve already formulated stuff so that more is not necessarily better. A crapload of money went into R&D, formulation, marketing, field performance evaluation, etc.

Suggestion - run the fluid as-is and keep those tiny bottles on the shelf. If you don’t get the slip or traction performance you expect, it’s easy enough to add a bottle later. You’re not gonna damage anything doing it this way.

I work in the chemical industry btw.

Suggestion - run the fluid as-is and keep those tiny bottles on the shelf. If you don’t get the slip or traction performance you expect, it’s easy enough to add a bottle later. You’re not gonna damage anything doing it this way.

I work in the chemical industry btw.

Ted

The pilot formerly known as Twin Engine Ted

- Joined

- Oct 9, 2007

- Messages

- 29,892

- Display Name

Display name:

iFlyNothing

Once again, tonight I managed to get exactly what I figured I would done. Got the ring gear on the differential and torqued down to 100 ft-lbs. I wasn't able to get the LocTite 638 specified in the instructions. However after looking at a few other people doing it, it seems that nobody else does this step. Given that the ring gear is an interference fit around the differential requiring use of the press and then the bolts torqued down to 100 ft-lbs, I'm inclined to agree that it's not really required. We'll see if I regret this decision later on, but it seems like a logical omission.

I also got the outer races for the pinion driven in. The outer race on the inside of the pumpkin I got a bit cocked the first time and so I had to give it a second try. It went in just fine that time.

At this point, what I really need to do next is set up the pinion and pumpkin and make sure I have the proper shims in there to get the right backlash and gear meshing pattern. I'll admit I'm not really looking forward to this as I've never done it before, and I have visions of taking this apart and putting it back together a bunch of times. We'll see what happens. I'm at the point where tomorrow night I could do it, although I might chicken out and instead do something like paint the brake calipers that I know I can get done and get right, saving the hard part for the weekend.

I also got the outer races for the pinion driven in. The outer race on the inside of the pumpkin I got a bit cocked the first time and so I had to give it a second try. It went in just fine that time.

At this point, what I really need to do next is set up the pinion and pumpkin and make sure I have the proper shims in there to get the right backlash and gear meshing pattern. I'll admit I'm not really looking forward to this as I've never done it before, and I have visions of taking this apart and putting it back together a bunch of times. We'll see what happens. I'm at the point where tomorrow night I could do it, although I might chicken out and instead do something like paint the brake calipers that I know I can get done and get right, saving the hard part for the weekend.

I'd go ahead and add another bottle of Ford friction modifier. I did when I changed out my differential fluid in the truck a few years ago. It won't hurt anything to have a little extra in there, as the bottles are pretty small.

After a diff oil change due to high water, I noticed the locker was popping in and out of lock. I asked my transmission guy about the Ford additive and he was extremely adamant about putting the exact amount in the oil. He said to make left and right turns for a few minutes and it will go away. It did.

SoonerAviator

Final Approach

- Joined

- Jul 21, 2014

- Messages

- 9,353

- Location

- Broken Arrow, OK

- Display Name

Display name:

SoonerAviator

After a diff oil change due to high water, I noticed the locker was popping in and out of lock. I asked my transmission guy about the Ford additive and he was extremely adamant about putting the exact amount in the oil. He said to make left and right turns for a few minutes and it will go away. It did.

Yeah, I changed mine due to having submerged the rear diff in a lake by my FIL when pulling our boat out. Didn't find any evidence of water intrusion, but it was cheap insurance to change out. The F-150 forums seem in agreement that you need to put the recommended amount in, and putting in a bit extra shouldn't hurt anything. I just put in straight diff fluid when I did mine. and added the Ford modifier as recommended.

Ted

The pilot formerly known as Twin Engine Ted

- Joined

- Oct 9, 2007

- Messages

- 29,892

- Display Name

Display name:

iFlyNothing

Interesting points regarding the friction modifier. That's not an area I know a ton about regarding quantities. Doing some Googling it seems most people do recommend putting in the bottle even when the gear oil says it has it already. I will probably put the bottle in and then reinvestigate if I have issues. I will end up doing a diff oil change at probably 500 or 1000 miles to account for break-in (which reminds me - I ought to look at the maintenance schedule on my Ram for which I've never changed the diff or transmission oil) and I can make adjustments then if need be.

One thing I forgot to note last night was that I put in the S-spring. I ended up using the original S-spring again that came out. The new one that came with the kit was just too tight and it ended up breaking while I was trying to get it in. I read that others using this same kit had the same problem and reused the spring that came out without issues. Given what I'm doing with the car I imagine it will be fine.

So tonight, I'll either start my initial work on trying to set up the rear end, or else I'll do some of the other work regarding painting/calipers/whatever. I'll see how I feel this evening.

Oh, and a few pictures...

Broken S-spring after trying to put it in the differential.

Fully assembled differential.

Outer bearing races installed.

One thing I forgot to note last night was that I put in the S-spring. I ended up using the original S-spring again that came out. The new one that came with the kit was just too tight and it ended up breaking while I was trying to get it in. I read that others using this same kit had the same problem and reused the spring that came out without issues. Given what I'm doing with the car I imagine it will be fine.

So tonight, I'll either start my initial work on trying to set up the rear end, or else I'll do some of the other work regarding painting/calipers/whatever. I'll see how I feel this evening.

Oh, and a few pictures...

Broken S-spring after trying to put it in the differential.

Fully assembled differential.

Outer bearing races installed.

Ted

The pilot formerly known as Twin Engine Ted

- Joined

- Oct 9, 2007

- Messages

- 29,892

- Display Name

Display name:

iFlyNothing

Well, as per the norm, I'm thinking about things more and may be coming back full circle.

I called up the machine shop on the heads. The heads are done but not assembled yet. I told them to hold off on assembly since I would be buying a cam kit with proper springs, so might as well let them assemble that. But those are good to go and the chambers are 56.5 ccs. Perfect for making about 10:1 compression with the short block setups I was looking at.

Then I called the machine shop I took the block to. They haven't touched it. I figured that was the case, said it would be a couple weeks yet. I know where this is going - they're not going to get it done in any reasonable amount of time. Time to call ATK on a short block.

Called ATK, they said they stopped selling the 331 short block entirely, and they actually don't sell 331s at all anymore, or any 302-based short blocks. They said they just have a hard time finding good 302 blocks and so the ones they do get they save for full on crate engines since there's more money in those. Totally understand and respect that. However their crate 351W they sell (which is $1k cheaper, and free shipping) is in stock, ready to ship. This was originally why I had thought I would go with a 351. More displacement, less money, and a stronger block/rotating assembly to handle the power I throw at it.

So then I went looking around at 331 stroker short blocks, and was reminded of one of the reasons I was going to go with ATK - they were the best value by several hundred bucks on what was already going to be a more expensive proposition. So that was a downer.

Then I called up Speedmaster to talk to them about their 8-stack EFI - basically EFI that looks like Webers. Originally, I had thought about going with a 351W also because their 8-stack injection is a really good value at around $850 including shipping. That still requires fuel injectors and a computer, but even factoring those in it's an easy $1k+ savings over Webers. I asked them about the fuel spitting issues that Webers have, and they said they've never heard of issues with that using their setup. While it wouldn't have the same sensitivity to needing vacuum like Webers do since the fuel is injected, I would imagine there would still be some sensitivity.

I'm back to thinking that a 351 is going to be the way to go for a few reasons. First, like I had originally figured it will save me money. I also now have a transmission that can handle whatever I can throw at it, and a 351 is going to be a lot tougher than a 302 which gives me some more freedom relative to power. Additionally while I do really want to do Webers at some point, my wife will be driving the car and I think she would appreciate the ease of starting that comes with EFI. I will have an extra 50 lbs up front but I'm cutting weight in enough other places that on the whole, the car will be lighter than a lot of 302 powered cars. The ability to also have some more flexibility for an off-the-shelf cam is also appealing rather than sticking to a super wide lobe separation angle. I really do want a good lope in there at idle. And when I ordered the kit, I also had planned on a 351 so I have 351 headers already. I was figuring out what exactly I was going to do with those. All around, this is a decision that will cost less, be easier, probably more durable/torquey, etc. The negatives are the extra weight - both in the block and rotating assembly - and also in having a bit less room under the hood to work on it. However, everyone who I talked to said they didn't find working on the 351 to be a problem at all in a Cobra.

It's Friday afternoon and I don't need any of this stuff tomorrow (nor would I get it anyway), so I'm not ordering anything. However I think I'm back to being settled on the 351. I'm going to think about it over the weekend some more and plan to start ordering parts on Monday. Input over the weekend while I'm thinking about all of this is welcome.

I called up the machine shop on the heads. The heads are done but not assembled yet. I told them to hold off on assembly since I would be buying a cam kit with proper springs, so might as well let them assemble that. But those are good to go and the chambers are 56.5 ccs. Perfect for making about 10:1 compression with the short block setups I was looking at.

Then I called the machine shop I took the block to. They haven't touched it. I figured that was the case, said it would be a couple weeks yet. I know where this is going - they're not going to get it done in any reasonable amount of time. Time to call ATK on a short block.

Called ATK, they said they stopped selling the 331 short block entirely, and they actually don't sell 331s at all anymore, or any 302-based short blocks. They said they just have a hard time finding good 302 blocks and so the ones they do get they save for full on crate engines since there's more money in those. Totally understand and respect that. However their crate 351W they sell (which is $1k cheaper, and free shipping) is in stock, ready to ship. This was originally why I had thought I would go with a 351. More displacement, less money, and a stronger block/rotating assembly to handle the power I throw at it.

So then I went looking around at 331 stroker short blocks, and was reminded of one of the reasons I was going to go with ATK - they were the best value by several hundred bucks on what was already going to be a more expensive proposition. So that was a downer.

Then I called up Speedmaster to talk to them about their 8-stack EFI - basically EFI that looks like Webers. Originally, I had thought about going with a 351W also because their 8-stack injection is a really good value at around $850 including shipping. That still requires fuel injectors and a computer, but even factoring those in it's an easy $1k+ savings over Webers. I asked them about the fuel spitting issues that Webers have, and they said they've never heard of issues with that using their setup. While it wouldn't have the same sensitivity to needing vacuum like Webers do since the fuel is injected, I would imagine there would still be some sensitivity.

I'm back to thinking that a 351 is going to be the way to go for a few reasons. First, like I had originally figured it will save me money. I also now have a transmission that can handle whatever I can throw at it, and a 351 is going to be a lot tougher than a 302 which gives me some more freedom relative to power. Additionally while I do really want to do Webers at some point, my wife will be driving the car and I think she would appreciate the ease of starting that comes with EFI. I will have an extra 50 lbs up front but I'm cutting weight in enough other places that on the whole, the car will be lighter than a lot of 302 powered cars. The ability to also have some more flexibility for an off-the-shelf cam is also appealing rather than sticking to a super wide lobe separation angle. I really do want a good lope in there at idle. And when I ordered the kit, I also had planned on a 351 so I have 351 headers already. I was figuring out what exactly I was going to do with those. All around, this is a decision that will cost less, be easier, probably more durable/torquey, etc. The negatives are the extra weight - both in the block and rotating assembly - and also in having a bit less room under the hood to work on it. However, everyone who I talked to said they didn't find working on the 351 to be a problem at all in a Cobra.

It's Friday afternoon and I don't need any of this stuff tomorrow (nor would I get it anyway), so I'm not ordering anything. However I think I'm back to being settled on the 351. I'm going to think about it over the weekend some more and plan to start ordering parts on Monday. Input over the weekend while I'm thinking about all of this is welcome.

Zeldman

Touchdown! Greaser!

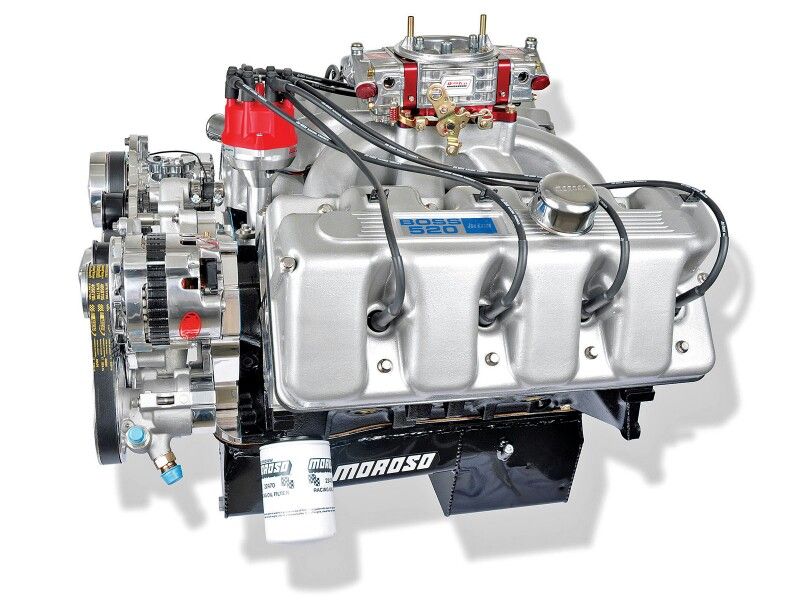

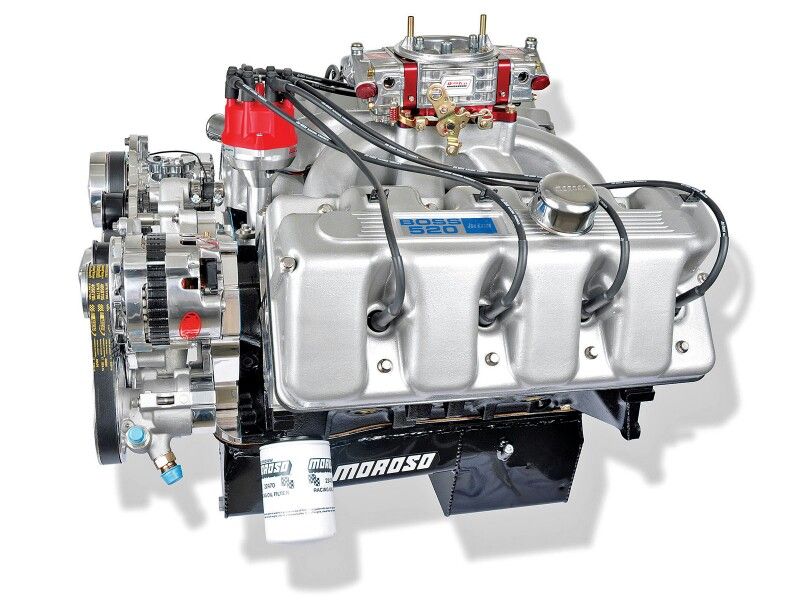

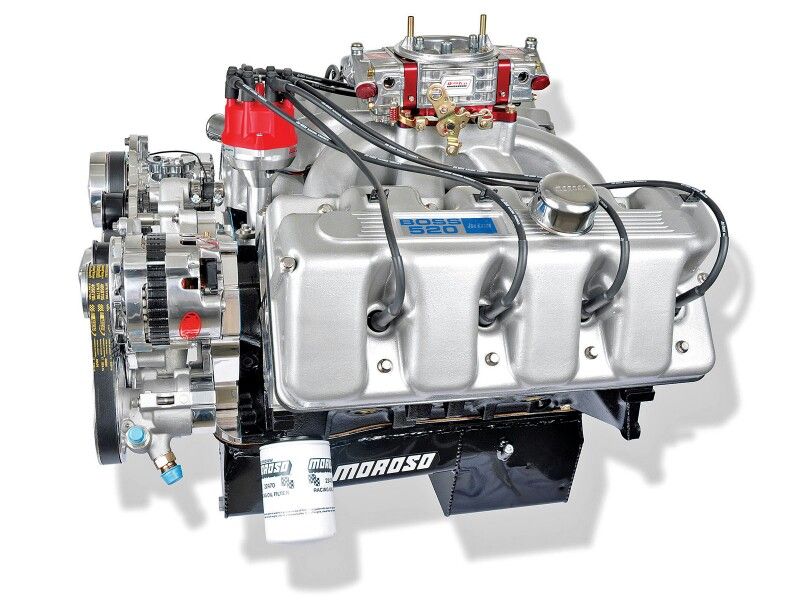

The Boss 520 is now available...

Just something to think about.....

Just something to think about.....

Ted

The pilot formerly known as Twin Engine Ted

- Joined

- Oct 9, 2007

- Messages

- 29,892

- Display Name

Display name:

iFlyNothing

The Boss 520 is now available...

Just something to think about.....

With prices starting at $20k, I’m going to have the whole car completed for not much more than the price of that engine.

I think I’ll pass.

Zeldman

Touchdown! Greaser!

With prices starting at $20k, I’m going to have the whole car completed for not much more than the price of that engine.

I think I’ll pass.

Plus you would need something like 48 inch wide rear tires....

Ted

The pilot formerly known as Twin Engine Ted

- Joined

- Oct 9, 2007

- Messages

- 29,892

- Display Name

Display name:

iFlyNothing

Plus you would need something like 48 inch wide rear tires....

Only?

So if I’m going EFI and I’m getting a controller that can control a distributor, do I go electronic (computer controlled) distributor or not? I’m thinking it’s kinda silly not to if I have that level of control capability and I’m buying a distributor anyway.

tmyers

En-Route

Electronics are your friend. Holley fuel injection and full on computer is what tamed my son's 574 into an engine that started and ran without having to be baby Sat till it warmed up.

Sent from my SM-N920V using Tapatalk

Sent from my SM-N920V using Tapatalk

Ted

The pilot formerly known as Twin Engine Ted

- Joined

- Oct 9, 2007

- Messages

- 29,892

- Display Name

Display name:

iFlyNothing

Fair points, Tim. The reality is that this isn't a car that will be a solely Ted car (at least I'm not expecting it to be). So while I'm happy with things being cantankerous and rather take pleasure in it, there's a lot of benefit to electronics.

Spent a bit of time in the garage tonight. I got the bearing off of the old pinion and got the shim off and measured it. It's right at 0.028" which is about where I wanted to start. So, perfect. I'll start there. I also assembled the rear coil-overs, easy enough to do. However, upon looking at the driveshaft flange, I'm also noting that it's got a noticeable wear mark that I can also feel with my finger. The front of the differential was leaking, so I think this is worth addressing. A new Ford Performance flange is $38 from Summit Racing so I'm just going to order that and do it right. At that point, the only spline/seal part that won't be new will be the spider gears that have the splines going to the axles. Given how little play existed in the rear end when I first played around with it, I'm not worried about there being drivetrain slop enough to bother me, even as particular as I am about drivetrain slop.

So now the plan for the weekend is to continue working on getting the rear end as close to ready as possible so that I just have to set up the gears and then install the axles and put it in. There's a good amount I can do to get it to that point still between painting, drilling out the holes, installing the mount for the 3-link, getting the panhard bar set up, things like that. I can also get started working on the brake lines going from the back of the car forward which I'd originally planned for the next week I had for working on the car.

I figure Monday I'll start ordering parts for the engine.

Spent a bit of time in the garage tonight. I got the bearing off of the old pinion and got the shim off and measured it. It's right at 0.028" which is about where I wanted to start. So, perfect. I'll start there. I also assembled the rear coil-overs, easy enough to do. However, upon looking at the driveshaft flange, I'm also noting that it's got a noticeable wear mark that I can also feel with my finger. The front of the differential was leaking, so I think this is worth addressing. A new Ford Performance flange is $38 from Summit Racing so I'm just going to order that and do it right. At that point, the only spline/seal part that won't be new will be the spider gears that have the splines going to the axles. Given how little play existed in the rear end when I first played around with it, I'm not worried about there being drivetrain slop enough to bother me, even as particular as I am about drivetrain slop.

So now the plan for the weekend is to continue working on getting the rear end as close to ready as possible so that I just have to set up the gears and then install the axles and put it in. There's a good amount I can do to get it to that point still between painting, drilling out the holes, installing the mount for the 3-link, getting the panhard bar set up, things like that. I can also get started working on the brake lines going from the back of the car forward which I'd originally planned for the next week I had for working on the car.

I figure Monday I'll start ordering parts for the engine.

Ted

The pilot formerly known as Twin Engine Ted

- Joined

- Oct 9, 2007

- Messages

- 29,892

- Display Name

Display name:

iFlyNothing

I’ve gotten enough people tell me I should make videos for YouTube. Doing edits isn’t really something I have time or interest for (at least not now), but I can easily do unedited one-takes with my phone.

I think I might try doing at least some of my updates and adding some background like that. I’ll post links (and embed them) as I get them posted.

I think I might try doing at least some of my updates and adding some background like that. I’ll post links (and embed them) as I get them posted.

Zeldman

Touchdown! Greaser!

I’ve gotten enough people tell me I should make videos for YouTube.

Just you tube the smoky fire breathing burnouts, that's all we are interested in seeing.....

SoonerAviator

Final Approach

- Joined

- Jul 21, 2014

- Messages

- 9,353

- Location

- Broken Arrow, OK

- Display Name

Display name:

SoonerAviator

Not saying I told you so, but . . . I’ve been recommending the 351w and TKO tranny since you started this thread, lol. You should have just listened to me from the beginning!

Now, the important question is 351w or 408w?

Now, the important question is 351w or 408w?

Ted

The pilot formerly known as Twin Engine Ted

- Joined

- Oct 9, 2007

- Messages

- 29,892

- Display Name

Display name:

iFlyNothing

Not saying I told you so, but . . . I’ve been recommending the 351w and TKO tranny since you started this thread, lol. You should have just listened to me from the beginning!

Now, the important question is 351w or 408w?

Fine, fine...

As I said, it comes full circle as the 351W and TKO was where I was when I ordered the kit in the first place. It's also worth noting that this is a decision driven to a large extent by finances and good deals as opposed to what I would want if I didn't care about the cost. I'm adding around 80 lbs to the car which I really don't want to add. Much of that weight is in rotating components (the engine rotating assembly as well as the transmission gears/shafts) so that will impact responsiveness. Yes, there are plenty of positives too and I'm confident I'll be happy with the result, but I also suspect I'll find myself wishing for a bit less weight and rotating mass.

This will be a 351W not a 408W. When I look at prices on 408W stroker short blocks that gets me right up to the 331 short block price range. Now you could argue that I'm still saving money by going with the EFI setup over Webers so it about breaks even, but given that I was planning around a 331 anyway, I don't see a real reason to go for a 408.

It's very common for people with these cars to change engines over the years. So, I'm also not stressing over it. I talked to a friend of mine who built one several years ago. He said he agonized over the decision for 302-based vs 351-based. He ended up going with a 351W, blew that up on a track day, and then put in a 408. He said he's had two different EFI systems on as well and now running a carb. These cars are, for many, never-ending projects and I'm sure that I'll find similar. If it bugs me enough I can always build a 331 or whatever down the road and swap it in. More likely, though, I'll be happy with the 351 and leave it be.

Today I haven't made all that much progress. I mostly worked on cleaning up the rear end some and getting it ready for paint. It's about ready, but then I dropped it on my right toe. Note to self: Tevas make poor replacements for steel toes. I guess I should be better about that.

But, I did get the upper 2 links of the 4-link removed (not required, but improves some clearance and saves a few ounces) and got the rear axle itself cleaned. I'll get a paint brush and the POR 15 and paint it, maybe tonight if I feel up to it but more likely tomorrow. My calipers and brake brackets are painted, so things are good there. After I paint the rear end I can bolt on the 3-link components as well as the brake caliper brackets.

I'm really debating whether I want to try just taking a chance on installing the pinion with the old shim or if I want to go to the trouble of planning to assemble/disassemble many times. I have two crush washers and nuts (both of which are supposed to be one-time use) so I could take a chance there. Thing is that if I'm wrong, the bearing won't be reusable when I pull it off, and then I also won't be able to reuse the seal. So, potential benefits either way.

Ted

The pilot formerly known as Twin Engine Ted

- Joined

- Oct 9, 2007

- Messages

- 29,892

- Display Name

Display name:

iFlyNothing

I've also decided to start doing some videos. Yeah, my phone sucks. But if you like reading the thread, maybe you'll like the videos too.

This one just starts with an overall outline of where things are now.

This one just starts with an overall outline of where things are now.

EppyGA

Touchdown! Greaser!

Did the kids learn any new words when you dropped the axle on your toe?

Ted

The pilot formerly known as Twin Engine Ted

- Joined

- Oct 9, 2007

- Messages

- 29,892

- Display Name

Display name:

iFlyNothing

Did the kids learn any new words when you dropped the axle on your toe?

Unlike my wife who has the vocabulary of a well-educated sailor, I am quite good at controlling my utilization of curse words, especially around the kids.

I've got my toe bandaged up, on ice, feet up. I guess it's time for me to get back to the garage - I still have 9 toes left so I'm good to go, right?

Ted

The pilot formerly known as Twin Engine Ted

- Joined

- Oct 9, 2007

- Messages

- 29,892

- Display Name

Display name:

iFlyNothing

Made some progress today in spite of my toe (which is feeling better than I'd expected, but still not pretty). The kids said they wanted to work on the Cobra, so alright, let's go to the garage. This time, steel toed shoes on!

The main thing I wanted to work on was painting the rear end. I had gotten a quart of POR 15 gloss black. I have to say, I'm impressed with how far it goes and how hard and nice of a finish it produces for just being something that looks like paint (even though it's a chemical that technically converts the rust). So we got that done, and I figured that'd be good to do before putting on some of the brackets and stuff.

I'm not sure if long term that was a good idea or not. Tonight I worked on putting some of the brackets on and that did seem to make things harder having the POR 15 on. I have to put on the brackets for the lower control arms and the shock mounts (different locations/orientations than Ford did) and also the upper link for the 3-link. That's a bracket that goes on pretty tight and is going to require some persuation with a hammer. I could've gotten it done tonight, but ultimately decided that it was late enough that I should go to bed. I'll probably get that finished up tomorrow, and then the rear end will be more or less ready to install in the car. Oh right, other than the differential being installed. Bah. Well, I'll get that done.

Another milestone: One more box of parts thrown away!

The main thing I wanted to work on was painting the rear end. I had gotten a quart of POR 15 gloss black. I have to say, I'm impressed with how far it goes and how hard and nice of a finish it produces for just being something that looks like paint (even though it's a chemical that technically converts the rust). So we got that done, and I figured that'd be good to do before putting on some of the brackets and stuff.

I'm not sure if long term that was a good idea or not. Tonight I worked on putting some of the brackets on and that did seem to make things harder having the POR 15 on. I have to put on the brackets for the lower control arms and the shock mounts (different locations/orientations than Ford did) and also the upper link for the 3-link. That's a bracket that goes on pretty tight and is going to require some persuation with a hammer. I could've gotten it done tonight, but ultimately decided that it was late enough that I should go to bed. I'll probably get that finished up tomorrow, and then the rear end will be more or less ready to install in the car. Oh right, other than the differential being installed. Bah. Well, I'll get that done.

Another milestone: One more box of parts thrown away!

Last edited:

EppyGA

Touchdown! Greaser!

It looks purty Ted.

Ted

The pilot formerly known as Twin Engine Ted

- Joined

- Oct 9, 2007

- Messages

- 29,892

- Display Name

Display name:

iFlyNothing

It looks purty Ted.

Thanks. The mismatched flat black powder coating and paint on the brackets vs. gloss black paint on the rear axle itself is something that's a bit sub-ideal, but nothing that anyone will really notice when I'm driving it.

Today should be an expensive day... planning on ordering a short block and some other engine parts.

Sac Arrow

Touchdown! Greaser!

- Joined

- May 11, 2010

- Messages

- 20,344

- Location

- Charlotte, NC

- Display Name

Display name:

Snorting his way across the USA

I feel a little weird telling Ted his rear end looks nice.

FormerHangie

En-Route

Thanks. The mismatched flat black powder coating and paint on the brackets vs. gloss black paint on the rear axle itself is something that's a bit sub-ideal, but nothing that anyone will really notice when I'm driving it.

Today should be an expensive day... planning on ordering a short block and some other engine parts.

Sorry it came to that, but I think you'll be pleased with the end result.

Ted

The pilot formerly known as Twin Engine Ted

- Joined

- Oct 9, 2007

- Messages

- 29,892

- Display Name

Display name:

iFlyNothing

Sorry it came to that, but I think you'll be pleased with the end result.

I think so too.

455 Bravo Uniform

Final Approach

I feel a little weird telling Ted his rear end looks nice.

No you don’t.

Ted

The pilot formerly known as Twin Engine Ted

- Joined

- Oct 9, 2007

- Messages

- 29,892

- Display Name

Display name:

iFlyNothing

Just called up Summit Racing and ordered a bunch of parts! Conveniently they're running a sale right now so I saved about $150 total. What I ordered:

- Engine: ATK 351W short block. I talked to ATK about this for a bit, and the guy actually recommended I order direct from Summit because it would save me some money. That's a positive in my book for honesty. We talked about power and my plans for the engine and he said it should be good, just don't rev it too high - 6k or so is about what I should plan for a max RPM. That's fine, that's what I was planning anyway. Guy was helpful

- Isky flat tappet cam and lifters. I talked to Isky about this one. Isky offers two lifter styles - one with a hole for extra oil flow to the cam. They said for what I'm doing there's no need for that, it's really more useful when you have a radical cam profile, which I'm not doing. The Isky lifters aren't the cheapest out there, but I figure that their lifters should hopefully match their cam somehow. It sounds good in my head anyway. This was the cam I mentioned a few pages back. It advertises around 226 degrees duration at 0.050" lift and .476" lift overall. With me using 1.7:1 rockers instead of 1.6, I'll have a bit more lift (a bit over .500") and a bit more duration at 0.050" (figure maybe 5-10 degrees since advertised duration is 270). Not too radical of a cam but it's advertised for 2,000-6,000 RPM and I think it'll work well with what I'm doing. Also got the appropriate assembly lube and break-in additive

- Timing gear drive. This is something that I wanted to experiment with. I went for a "quiet" version. I like gear noise and I think I'll have enough of it. I've not played with gear drives before and it appeals to me because it's one more area of miniscule lag I'll be removing. I realize I don't need it for any technical purpose, but I'm doing it anyway.

- Appropriate ARP (repackaged by Edelbrock) head bolts as well as the appropriate head gaskets

- A pushrod length checker that will let me determine what length pushrods I need. Better to do this one right the first time

- Last but not least, the flange I need for the differential

The woman from Summit Racing who I talked to was very helpful. I will say that the people from Edelbrock tech support I find are not helpful at all. Whenever I've called them they seem annoyed to be talking to me and then their response is always "I can't give you any useful info." I'm not sure what their deal is but Edelbrock could sure stand to change their customer service reps up a bit. Out of the 4 companies I called today, Edelbrock was the only one who made me not want to buy their products.

It looks as though the valve springs I already have should work. I talked to Isky and got their recommendation on spring pressures, and that matches what Edelbrock says the springs ought to be. I'm having the machine shop that has the heads double check them to confirm and then once they confirm it's all good, I can have them put the things back together and pick them up hopefully sometime this week.

Some of the parts will arrive a bit out of order, but on the whole it should be fine. The Isky cam isn't expected to ship for about 2 weeks, so I will be waiting on that more than anything before I can really start putting the engine together since I'll have to check the piston to valve clearance before I torque down the heads. Everything I've read said that it should be fine with the lift, heads, and pistons I'm running, however it'd be wise to double check that so I'm going to before I bolt things down and then break a bunch of money worth of equipment.

- Engine: ATK 351W short block. I talked to ATK about this for a bit, and the guy actually recommended I order direct from Summit because it would save me some money. That's a positive in my book for honesty. We talked about power and my plans for the engine and he said it should be good, just don't rev it too high - 6k or so is about what I should plan for a max RPM. That's fine, that's what I was planning anyway. Guy was helpful

- Isky flat tappet cam and lifters. I talked to Isky about this one. Isky offers two lifter styles - one with a hole for extra oil flow to the cam. They said for what I'm doing there's no need for that, it's really more useful when you have a radical cam profile, which I'm not doing. The Isky lifters aren't the cheapest out there, but I figure that their lifters should hopefully match their cam somehow. It sounds good in my head anyway. This was the cam I mentioned a few pages back. It advertises around 226 degrees duration at 0.050" lift and .476" lift overall. With me using 1.7:1 rockers instead of 1.6, I'll have a bit more lift (a bit over .500") and a bit more duration at 0.050" (figure maybe 5-10 degrees since advertised duration is 270). Not too radical of a cam but it's advertised for 2,000-6,000 RPM and I think it'll work well with what I'm doing. Also got the appropriate assembly lube and break-in additive

- Timing gear drive. This is something that I wanted to experiment with. I went for a "quiet" version. I like gear noise and I think I'll have enough of it. I've not played with gear drives before and it appeals to me because it's one more area of miniscule lag I'll be removing. I realize I don't need it for any technical purpose, but I'm doing it anyway.

- Appropriate ARP (repackaged by Edelbrock) head bolts as well as the appropriate head gaskets

- A pushrod length checker that will let me determine what length pushrods I need. Better to do this one right the first time

- Last but not least, the flange I need for the differential

The woman from Summit Racing who I talked to was very helpful. I will say that the people from Edelbrock tech support I find are not helpful at all. Whenever I've called them they seem annoyed to be talking to me and then their response is always "I can't give you any useful info." I'm not sure what their deal is but Edelbrock could sure stand to change their customer service reps up a bit. Out of the 4 companies I called today, Edelbrock was the only one who made me not want to buy their products.

It looks as though the valve springs I already have should work. I talked to Isky and got their recommendation on spring pressures, and that matches what Edelbrock says the springs ought to be. I'm having the machine shop that has the heads double check them to confirm and then once they confirm it's all good, I can have them put the things back together and pick them up hopefully sometime this week.

Some of the parts will arrive a bit out of order, but on the whole it should be fine. The Isky cam isn't expected to ship for about 2 weeks, so I will be waiting on that more than anything before I can really start putting the engine together since I'll have to check the piston to valve clearance before I torque down the heads. Everything I've read said that it should be fine with the lift, heads, and pistons I'm running, however it'd be wise to double check that so I'm going to before I bolt things down and then break a bunch of money worth of equipment.

Ted

The pilot formerly known as Twin Engine Ted

- Joined

- Oct 9, 2007

- Messages

- 29,892

- Display Name

Display name:

iFlyNothing

Just spent some more money, ordered the Speedmaster downdraft EFI Weber-lookalike setup. At about 1/3 the price of Webers, there's a lot of value there. By the time I spend the money on a MicroSquirt (yes that's the name) and injectors I'll be at about half the cost of Webers. with the benefits of EFI. I had good reasons (in my head anyway) for Webers so I'm a bit disappointed on that, but ultimately this just makes more sense I think.

Basically, for what the Webers would've cost on their own, I've gotten the complete engine and air intake setup, as well as the little drop-in K&N air filters for the individual throttle stacks. Like I said, I'll have a bit more money into the injectors and the computer, but that'll do what I need it to. I also will have to order some other parts for the engine - some gaskets, the harmonic balancer, I don't think this comes with an oil pump, I will need to pick a distributor, etc. I haven't opened it up but I'm pretty sure that I'm just going to buy a new fuel tank with pump, etc. There's a setup that has a brand new tank, Walbro 255 LPH fuel pump, fuel sending unit, etc. etc. for a bit over $300. That's a good deal and to me makes that something of a no-brainer.

Tonight I can hopefully make some more progress on the rear end. The new flange should show up on Wednesday, but I don't expect to make any progress on the rear end this weekend since my wife's home and we'll be working on other projects.

Basically, for what the Webers would've cost on their own, I've gotten the complete engine and air intake setup, as well as the little drop-in K&N air filters for the individual throttle stacks. Like I said, I'll have a bit more money into the injectors and the computer, but that'll do what I need it to. I also will have to order some other parts for the engine - some gaskets, the harmonic balancer, I don't think this comes with an oil pump, I will need to pick a distributor, etc. I haven't opened it up but I'm pretty sure that I'm just going to buy a new fuel tank with pump, etc. There's a setup that has a brand new tank, Walbro 255 LPH fuel pump, fuel sending unit, etc. etc. for a bit over $300. That's a good deal and to me makes that something of a no-brainer.

Tonight I can hopefully make some more progress on the rear end. The new flange should show up on Wednesday, but I don't expect to make any progress on the rear end this weekend since my wife's home and we'll be working on other projects.

Zeldman

Touchdown! Greaser!

as well as the little drop-in K&N air filters for the individual throttle stacks.

I hope K&N filters have changed and are not those foam rubber things that is supposed to use oil to filter the air. They flow better than other filters but.... they don't filter very well at all. And one speck too much oil and the oil gets sucked into the engine.

I haven't used or suggested K&N filters ever since mass air flow sensors have been put on cars.

Ted

The pilot formerly known as Twin Engine Ted

- Joined

- Oct 9, 2007

- Messages

- 29,892

- Display Name

Display name:

iFlyNothing

I hope K&N filters have changed and are not those foam rubber things that is supposed to use oil to filter the air. They flow better than other filters but.... they don't filter very well at all. And one speck too much oil and the oil gets sucked into the engine.

I haven't used or suggested K&N filters ever since mass air flow sensors have been put on cars.

Valid points. Here's my view on K&Ns.

If you're using a car with a hot-wire MAF, then a K&N should never go on it. It will inevitably get oil on the MAF and then your car won't run right. I've had that happen on two vehicles - my wife's former Avalanche and also our BMW 740iL.

If you're using a car that uses MAP, Alpha-N, or some alternative MAF sensors (such as a Karman type) then a K&N can provide better flow albeit at the price of filtration. Whether or not the filtration causes a problem with engine longevity is debatable and also depends on the kinds of roads/conditions you're driving on. I ran a K&N on my 3000GT VR-4 for about 40,000 miles and it did provide improved airflow over the stock airbox with no negative side effects. The VR-4 used a Karman-style MAF. I have no idea how exactly that worked compared to a hot-wire, but it wasn't impacted by the K&N at all.

For the Weber-style induction on the Cobra, a K&N will be fine in my opinion. Yes, the filtration is worse than a paper filter. However the K&Ns will last forever, there's not much surface area (so I'll probably clean them very regularly) and the other alternative is mesh screens which basically just keep the rocks out. I'm not using a MAF sensor, it will either be MAP or Alpha-N (TPS based) EFI. So for those, I think K&Ns will be better than mesh screens.

Now time to get back out to the garage...

Give credit where credit is due.I feel a little weird telling Ted his rear end looks nice.

Ted

The pilot formerly known as Twin Engine Ted

- Joined

- Oct 9, 2007

- Messages

- 29,892

- Display Name

Display name:

iFlyNothing

Didn't get far this evening at all, at least not aesthetically. I bolted down the bracket for the 3rd link in the 3-link suspension. I also drilled the hole in the forward portion of the differential. However, I am thoroughly displeased with the bolt Factory Five provided. The hole in the bracket is 1/2" and the bolt they provide is 3/8". Looking at the geometry and what the bolt does this probably isn't an issue, however I'm going to be buying a 1/2" grade 8 bolt to replace it with and install. There have been several areas where I've felt the hardware was shorter than desired, but this one is the first where I've felt the diameter is too small, too.

My wife comes home tomorrow so I imagine I won't get much done over the next week, but I will start to get parts rolling in so I'll take some pictures of those. My guess is this weekend will be working on things on the property... mowing, bulldozing trees, etc. etc.

My wife comes home tomorrow so I imagine I won't get much done over the next week, but I will start to get parts rolling in so I'll take some pictures of those. My guess is this weekend will be working on things on the property... mowing, bulldozing trees, etc. etc.

455 Bravo Uniform

Final Approach

Congrats on making a cam choice. Going with Isky’s recommended lifters was a good move.

It wouldn’t hurt to also double check the valve spring specs match the springs you got, and that the machine shop set them up with the proper closed height (closed pressure).

Been following along for a while and am kinda bummed no Webers, but I get it.

You do you on that gear drive! Hope you can hear it just enough.

Can’t remember, did you have an exhaust figured out yet?

I’ll have to research some to see how that injection system is related to Megasquirt, never heard of Micro, but been away from hotrod stuff for a while.

It wouldn’t hurt to also double check the valve spring specs match the springs you got, and that the machine shop set them up with the proper closed height (closed pressure).

Been following along for a while and am kinda bummed no Webers, but I get it.

You do you on that gear drive! Hope you can hear it just enough.

Can’t remember, did you have an exhaust figured out yet?

I’ll have to research some to see how that injection system is related to Megasquirt, never heard of Micro, but been away from hotrod stuff for a while.