jesse

Touchdown! Greaser!

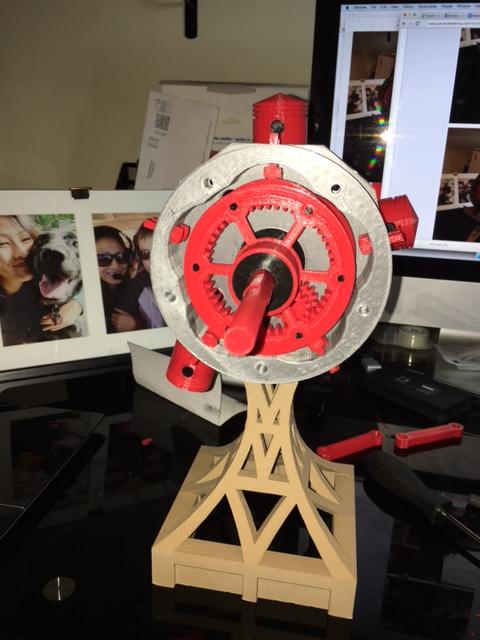

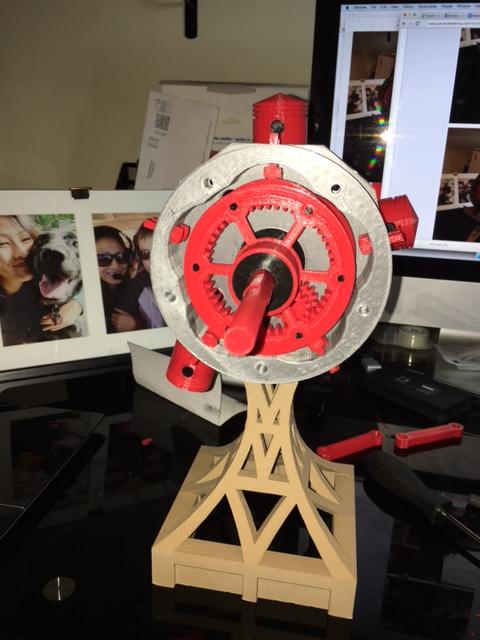

I've been working on building a 5 cylinder radial engine for my Dad for Christmas. Obviously this isn't going to be something you can add fuel, air, and spark to without a death wish. But it's still pretty cool to look at since the pistons and valves will all move properly. I'm half tempted to make some spark plugs with some LED(s) and get those to light at the right time as well but will probably skip that to make the Christmas delivery date.

This is where I stand so far. The 3d printer has been running non-stop for the last week. I have about another weeks worth of printing left to print the cylinders and a few other things.

The case will be silver, all the moving parts will be red, bearings, pins, and cylinders black.

The stand is made out of a hybrid wood/plastic that is probably about 30 percent wood. The cool part is it takes on some of the features of wood like the ability to sand and stain. The plan is to apply an oil based stain to the stand and then seal with a polyacrilic finish.

I'll make the prop out of the wood hybrid and will do a similar treatment to it as well.

Said and done the engine will be an assembly of roughly 270 parts all made on my 3D printer.

This is where I stand so far. The 3d printer has been running non-stop for the last week. I have about another weeks worth of printing left to print the cylinders and a few other things.

The case will be silver, all the moving parts will be red, bearings, pins, and cylinders black.

The stand is made out of a hybrid wood/plastic that is probably about 30 percent wood. The cool part is it takes on some of the features of wood like the ability to sand and stain. The plan is to apply an oil based stain to the stand and then seal with a polyacrilic finish.

I'll make the prop out of the wood hybrid and will do a similar treatment to it as well.

Said and done the engine will be an assembly of roughly 270 parts all made on my 3D printer.

Last edited:

.....

.....

The possibilities are exponential!

The possibilities are exponential!