ipengineer

Pre-Flight

Me and a partner are looking into purchasing a 2005 SR22 and it has got me looking into engine overhaul time. Do most people here follow manufactures TBO? Some of the planes we are looking at are over TBO and others are getting close to it.

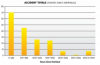

I came across this post on the AOPA blog which questions if Engine TBO's make sense. From looking at the graph it seems like the majority of engine failures are from engines recently overhauled. This makes sense to me; I can think of a lot of things that become less stable with change.

http://blog.aopa.org/opinionleaders/2014/03/13/do-tbos-make-sense/

I came across this post on the AOPA blog which questions if Engine TBO's make sense. From looking at the graph it seems like the majority of engine failures are from engines recently overhauled. This makes sense to me; I can think of a lot of things that become less stable with change.

http://blog.aopa.org/opinionleaders/2014/03/13/do-tbos-make-sense/