You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

If [BLANK] is what you find too expensive about flying...

- Thread starter DJTorrente

- Start date

ArrowFlyer86

Pattern Altitude

- Joined

- Jul 17, 2019

- Messages

- 1,611

- Location

- Chicago suburbs

- Display Name

Display name:

The Little Arrow That Could

Let's make it more realistic.

There should be a 4th bag labeled "FAA approved airplane screwdriver, serial number FU-LOL-123499PX" for $159.99. Backordered for 3 months.

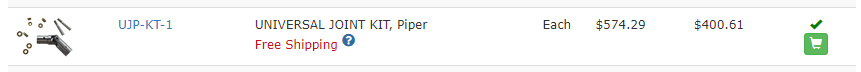

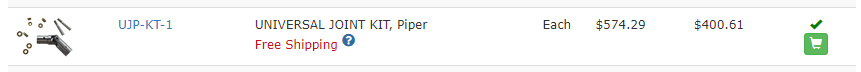

And what a timely topic b/c yesterday I just did a walkthrough on my discrepancy list for the arrow annual and the A&P suggested I should consider changing the universal joint used in the co-pilot side yoke in the next few years. Out of curiosity I looked up those joints.

A basic ******* joint for $400...

Hindsight is exactly right - the prices on these things feel designed to keep people out of the hobby. There's no practical reason for *some* of this stuff to cost what it does.

But, as one of my favorite sayings goes... When you see something that doesn't make sense - you can usually find the hand of government not far away.

*stares down FAA*

There should be a 4th bag labeled "FAA approved airplane screwdriver, serial number FU-LOL-123499PX" for $159.99. Backordered for 3 months.

And what a timely topic b/c yesterday I just did a walkthrough on my discrepancy list for the arrow annual and the A&P suggested I should consider changing the universal joint used in the co-pilot side yoke in the next few years. Out of curiosity I looked up those joints.

A basic ******* joint for $400...

Hindsight is exactly right - the prices on these things feel designed to keep people out of the hobby. There's no practical reason for *some* of this stuff to cost what it does.

But, as one of my favorite sayings goes... When you see something that doesn't make sense - you can usually find the hand of government not far away.

*stares down FAA*

MauleSkinner

Touchdown! Greaser!

No, they’re designed to keep the manufacturers from subsidizing your airplane.Hindsight is exactly right - the prices on these things feel designed to keep people out of the hobby. There's no practical reason for *some* of this stuff to cost what it does.

How so?There's no practical reason for *some* of this stuff to cost what it does.

You can always try and produce your own parts under Part 21.9(a)(5) if you think something is too expensive?

I think it is because it is such a small market and like said lawyers.

I would do it as soon as you can so you can get some value out of it. Plus it seems like a safety issue ?

I would do it as soon as you can so you can get some value out of it. Plus it seems like a safety issue ?

ArrowFlyer86

Pattern Altitude

- Joined

- Jul 17, 2019

- Messages

- 1,611

- Location

- Chicago suburbs

- Display Name

Display name:

The Little Arrow That Could

I don't think I'll be building a universal joint myself, but there's other components where I think it might make sense to go this route.How so?

You can always try and produce your own parts under Part 21.9(a)(5) if you think something is too expensive?

I'm curious how tolerant A&Ps are of using an owner supplied part and signing off on it, though? I've never tried but perhaps I should for some basic pieces. I assume they're taking risk if they sign off on an owner supplied part and it fails.

It's not a safety issue at this point - I made sure to clarify that. And I won't wait until it is.I think it is because it is such a small market and like said lawyers.

I would do it as soon as you can so you can get some value out of it. Plus it seems like a safety issue ?

Their view was in a few years it'll probably be time to replace it. That is not a component I would consider running until failure for obvious reasons

That's fair. For many components I can see that being the case.No, they’re designed to keep the manufacturers from subsidizing your airplane.

$400 part x2 yokes... So now I'm up to a dime per day!A $400 part that should last 20+ years is a nickel a day.

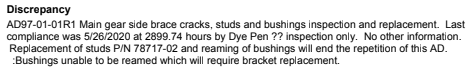

View attachment 128802

MauleSkinner

Touchdown! Greaser!

Yup…if a manufacturer has to have some number of them made just to warrant production, and they maybe sell just a few per year, that’s money tied up in inventory…including storage facilities, faculty, utilities, their cost could easily approach $400 for that part.That's fair. For many components I can see that being the case.

My a&p suggested the OPP route for the cabin heat box. I think it depends on the part...and owner skillsetI don't think I'll be building a universal joint myself, but there's other components where I think it might make sense to go this route.

I'm curious how tolerant A&Ps are of using an owner supplied part and signing off on it, though? I've never tried but perhaps I should for some basic pieces. I assume they're taking risk if they sign off on an owner supplied part and it fails.

"A nickel ain't worth a dime anymore"I don't think I'll be building a universal joint myself, but there's other components where I think it might make sense to go this route.

I'm curious how tolerant A&Ps are of using an owner supplied part and signing off on it, though? I've never tried but perhaps I should for some basic pieces. I assume they're taking risk if they sign off on an owner supplied part and it fails.

It's not a safety issue at this point - I made sure to clarify that. And I won't wait until it is.

Their view was in a few years it'll probably be time to replace it. That is not a component I would consider running until failure for obvious reasons

That's fair. For many components I can see that being the case.

$400 part x2 yokes... So now I'm up to a dime per day!

-Yogi Berra

Chrisgoesflying

Cleared for Takeoff

For me it was a fuel pump. Automotive fuel pump is the exact same as the aviation one, just without the sticker. Same brand/manufacturer, same components, etc. The auto version was $50, the aviation one was $250.

My mechanic just bought the automotive one, used the components of it to rebuild my aviation one and called it "refurbished" lol. Took him 10 minutes to do it.

My mechanic just bought the automotive one, used the components of it to rebuild my aviation one and called it "refurbished" lol. Took him 10 minutes to do it.

If the part is produced properly and the mechanic understands the process they are very tolerant. Have installed many owner parts.I'm curious how tolerant A&Ps are of using an owner supplied part and signing off on it, though?

FYI: the owner technically doesn't have to participate in the actual manufacture. However, the owner must participate in one of five defined ways for the part to be considered owner produced. To me, the deciding part is the who, what, where, how the approved data for the part is acquired that drives whether it is worth pursuing an owner part.I think it depends on the part...and owner skillset

The sticker makes it legal in most cases, however, there is guidance, eg., AC 23-27, where you could use the Gates $39 part directly with certain Part 91 aircraft. Regardless, part of the reason for the requirement of the Piper or other similar decal on OTC items is related to Block 6 on the aircraft AWC.There's a Piper sticker on the Gates bag.

MauleSkinner

Touchdown! Greaser!

Rereading this, however, I’m glad I never got into drugs. They’re expensive!A basic ******* joint for $400...

ArrowFlyer86

Pattern Altitude

- Joined

- Jul 17, 2019

- Messages

- 1,611

- Location

- Chicago suburbs

- Display Name

Display name:

The Little Arrow That Could

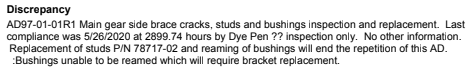

There are some parts where I just cannot wrap my head around the price.

This one, from back when I first bought my aircraft, probably takes the cake.

I remember being distinctly underwhelmed when I googled the part number and saw a component that looked like this.

It was that exact moment in my aircraft ownership experience where I realized I'd made a terrible mistake getting into airplanes

Though I do wonder... Would "owner supplied part" cover some enterprising individual who went to a machine shop and had 250 of these made and then sold them to owners for half the price?

Could an owner then "source" such a component with documentation behind its manufacturing and tell the A&P they want to use it as an owner supplied part? Or does the owner literally have to make it? (I realize I should probably just read the regs lol)

This one, from back when I first bought my aircraft, probably takes the cake.

I remember being distinctly underwhelmed when I googled the part number and saw a component that looked like this.

It was that exact moment in my aircraft ownership experience where I realized I'd made a terrible mistake getting into airplanes

Though I do wonder... Would "owner supplied part" cover some enterprising individual who went to a machine shop and had 250 of these made and then sold them to owners for half the price?

Could an owner then "source" such a component with documentation behind its manufacturing and tell the A&P they want to use it as an owner supplied part? Or does the owner literally have to make it? (I realize I should probably just read the regs lol)

Timbeck2

Final Approach

Let's make it more realistic.

There should be a 4th bag labeled "FAA approved airplane screwdriver, serial number FU-LOL-123499PX" for $159.99. Backordered for 3 months.

And what a timely topic b/c yesterday I just did a walkthrough on my discrepancy list for the arrow annual and the A&P suggested I should consider changing the universal joint used in the co-pilot side yoke in the next few years. Out of curiosity I looked up those joints.

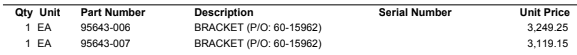

View attachment 128800

A basic ******* joint for $400...

Hindsight is exactly right - the prices on these things feel designed to keep people out of the hobby. There's no practical reason for *some* of this stuff to cost what it does.

But, as one of my favorite sayings goes... When you see something that doesn't make sense - you can usually find the hand of government not far away.

*stares down FAA*

You’re leaving out the fee to match drill the old one to the new one and removal and installation but yeah, I feel your pain

hindsight2020

Final Approach

- Joined

- Apr 3, 2010

- Messages

- 6,777

- Display Name

Display name:

hindsight2020

FTFY.where I realized I'd made a terrible mistake getting into Standard AWC-enslaved airplanes

FastEddieB

Touchdown! Greaser!

- Joined

- Oct 14, 2013

- Messages

- 11,484

- Location

- Lenoir City, TN/Mineral Bluff, GA

- Display Name

Display name:

Fast Eddie B

A basic ******* joint for $400...

We needed something similar for the PTO of our little John Deere tractor.

If I recall correctly, it was close to double that!

Was aware the owner didn't actually have to make it. I think Bogert considers their p-leads owner produced because the owner tells them length? Seems fringy to me.FYI: the owner technically doesn't have to participate in the actual manufacture. However, the owner must participate in one of five defined ways for the part to be considered owner produced. To me, the deciding part is the who, what, where, how the approved data for the part is acquired that drives whether it is worth pursuing an owner part.

Half Fast

Touchdown! Greaser!

However, the owner must participate in one of five defined ways for the part to be considered owner produced.

Hmmm... I counted six.

Participating in the design of the part can include supervising the

manufacture of the part or providing the manufacturer with the following: the design data, the

materials with which to make the part, the fabrication processes, assembly methods, or the

quality control (QC) procedures.

If I'm interpreting that correctly, if you just watch someone make the part (supervising) to ensure it's made properly, it's an OPP. Or you could just give a machine shop the raw material and the old part and say "Make a new one" and it's an OPP.

For simple parts, that's not a terribly high barrier.

@ArrowFlyer86 , for that U-joint, you might check to see if there's a replacement made to an established specification, like an SAE spec. If so, it could be considered a standard part (see AC-20-62). Lots of pieces on these old planes were common parts found on cars, trailers, etc.

Half Fast

Touchdown! Greaser!

Would "owner supplied part" cover some enterprising individual who went to a machine shop and had 250 of these made and then sold them to owners for half the price?

Could an owner then "source" such a component with documentation behind its manufacturing and tell the A&P they want to use it as an owner supplied part? Or does the owner literally have to make it? (I realize I should probably just read the regs lol)

It's been done.

For the part to be "Owner Produced" the airplane owner would have to provide you with data to manufacture the part. You could, for example, provide him with a partial drawing of the part which he would then complete, adding his N# at least, and the owner would then send you the drawing with instructions to make one for him. Alternatively, he could send you his old part and tell you to make a new one just like it, except without the damage.

SoonerAviator

Final Approach

- Joined

- Jul 21, 2014

- Messages

- 9,454

- Location

- Broken Arrow, OK

- Display Name

Display name:

SoonerAviator

You down with O.P.P.?

So how much do you think it should cost?There are some parts where I just cannot wrap my head around the price.

Not really. There are some parts that are simply not procurable. Sometimes you just need to be thankful you can get the part. As said many times these aircraft were never meant to last 50+ years on many levels.This one, from back when I first bought my aircraft, probably takes the cake.

You cannot sell owner parts. They are only applicable to the owners or in some cases the direct operators aircraft. Now theres nothing that says you couldnt sell the idea or plans you developed to someone else which has been done. But each individual owner that bought those plans would have to get their own specific data approvals for those plans. If that makes sense. However, there have been times when a group of owners have pooled their resources togather and each got an approved owner part out of the deal.Would "owner supplied part" cover some enterprising individual who went to a machine shop and had 250 of these made and then sold them to owners for half the price?

No. The owner must participate in one of the 5 methods listed below.Could an owner then "source" such a component with documentation behind its manufacturing and tell the A&P they want to use it as an owner supplied part? Or does the owner literally have to make it?

Cannot purchase owner parts. But nothing wrong what bogerts does except they charge a premium for cut wire. To make this an owner part the owner would require bogerts to manufacture the wire itself from raw materials to a spec.I think Bogert considers their p-leads owner produced because the owner tells them length?

5. Straight from the 1993 LOI:Hmmm... I counted six.

1. provide the manufacturer with the design or performance data from which to make the part, or

2. provide the manufacturer with the materials to make the part or,

3. provide the manufacturer with fabrication processes or assembly methods to make the part or,

4. provide the quality control procedures to make the part or’

5. personally supervised the manufacturer of the part.

Last edited:

Daleandee

Final Approach

- Joined

- Mar 4, 2020

- Messages

- 6,432

- Display Name

Display name:

Dale Andee

So how much do you think it should cost?

Not really. There are some parts that are simply not procurable. Sometimes you just need to be thankful you can get the part. As said many times these aircraft were never meant to last 50+ years on many levels.

You cannot sell owner parts. They are only applicable to the owners or in some cases the direct operators aircraft. Now theres nothing that says you couldnt sell the idea or plans you developed to someone else which has been done. But each individual owner that bought those plans would have to get their own specific data approvals for those plans. If that makes sense. However, there have been times when a group of owners have pooled their resources togather and each got an approved owner part out of the deal.

No. The owner must participate in one of the 5 methods listed below.

Cannot purchase owner parts. But nothing wrong what bogerts does except they charge a premium for cut wire. To make this an owner part the owner would require bogerts to manufacture the wire itself from raw materials to a spec.

5. Straight from the 1993 LOI:

1. provide the manufacturer with the design or performance data from which to make the part, or

2. provide the manufacturer with the materials to make the part or,

3. provide the manufacturer with fabrication processes or assembly methods to make the part or,

4. provide the quality control procedures to make the part or’

5. personally supervised the manufacturer of the part.

Does number two include ... cold hard cash?

ArrowFlyer86

Pattern Altitude

- Joined

- Jul 17, 2019

- Messages

- 1,611

- Location

- Chicago suburbs

- Display Name

Display name:

The Little Arrow That Could

Thank you @Bell206 for the complete response.

In terms of my comment regarding my "brackets take the cake" statement, that's from my POV. I know there's people with maintenance bills/heartaches far beyond my own.

But when I saw those brackets for $3k (x2 of them) I nearly shat a brick because it's not a complex component.

And though I don't consider myself to be the arbiter of what everything should cost in the market, as a customer I can't help but feel like this is a regulation induced shortage.

It's not that no one can or no one is willing to make a cheaper and equally reliable bracket for less than the $3000 price listed, it's that if someone DID make it they couldn't sell it to anyone for use in an aircraft.

Instead you have to make them 1 by 1 as a custom job, with the owner involved, which prevents you from getting any economies of scale. In turn making the existing exorbitantly priced items cheap by comparison.

So we're stuck constantly existing at the steepest/highest point of marginal cost on the classic economics price/quantity chart - purely as an artifact of regulation.

In terms of my comment regarding my "brackets take the cake" statement, that's from my POV. I know there's people with maintenance bills/heartaches far beyond my own.

But when I saw those brackets for $3k (x2 of them) I nearly shat a brick because it's not a complex component.

And though I don't consider myself to be the arbiter of what everything should cost in the market, as a customer I can't help but feel like this is a regulation induced shortage.

It's not that no one can or no one is willing to make a cheaper and equally reliable bracket for less than the $3000 price listed, it's that if someone DID make it they couldn't sell it to anyone for use in an aircraft.

Instead you have to make them 1 by 1 as a custom job, with the owner involved, which prevents you from getting any economies of scale. In turn making the existing exorbitantly priced items cheap by comparison.

So we're stuck constantly existing at the steepest/highest point of marginal cost on the classic economics price/quantity chart - purely as an artifact of regulation.

Klaus M

Pre-takeoff checklist

This is the Piper manifold pressure gauge air filter. You need two for a twin engine aircraft. Maybe these filters could be OPP depends on the owner.

Half Fast

Touchdown! Greaser!

5. Straight from the 1993 LOI:

It’s the same list. #3 actually contains two, since there’s an “or” statement separating fabrication processes and assembly methods.

Except aviation has never been about "economies of scale" simply due to regulation and international regulation at that. Outside of nuclear power generation, the aviation industry is the most regulated industry around. And for good reason in my opinion. Regardless, the one thing omitted from your landing gear part above was (I will assume) the owner elected for the terminating action of the AD vs simply performing the repetitive inspection. It was the terminating action attempt that scrapped the fittings which may have still been serviceable today. Then again I just replaced my kitchen stove because one module on the main control board failed and the cost of a new board was 2x the cost of new stove.... Maybe they have learned something from our side????So we're stuck constantly existing at the steepest/highest point of marginal cost on the classic economics price/quantity chart - purely as an artifact of regulation.

But not the FAA official list of five items.It’s the same list.

Yea, you know me!You down with O.P.P.?

But... "Free shipping". WINNING!A basic ******* joint for $400...

*stares down FAA*

Huckster79

Pattern Altitude

- Joined

- Nov 22, 2018

- Messages

- 2,345

- Display Name

Display name:

Huckster79

They are pricey, I replaced mine in my ol Cessna 140. Elected just to do pilot side, and man it seemed insane paying for that part- BUT after it was on I felt it was worth the $350 or whatever it was- the plane felt like your car does after ya get new tires and an alignment… it was a marked difference in feel of the bird with the u joint slop eliminated.

Don’t blame ya for the sticker shock- but the results may give you some solace in the expense…

Don’t blame ya for the sticker shock- but the results may give you some solace in the expense…

EdFred

Taxi to Parking

Except when the part number is literally a $1 part and they sell it/repair it for $900.Yup…if a manufacturer has to have some number of them made just to warrant production, and they maybe sell just a few per year, that’s money tied up in inventory…including storage facilities, faculty, utilities, their cost could easily approach $400 for that part.

Dad had a contact switch that was bad in the stall warning in the Cherokee 180. They wanted $900 to replace it. He took it apart and found that it was only the electronic switch that was bad. He tracked down the company that made the switch. They had it on their website for a buck and some change. He went to order it, verified the price, and when they went to complete the order they said that part is only available for sale to Piper. It's literally a $1 and some change switch that they are marking up to over $900. Piper doesn't even make the part. They didn't design the part. So the whole manufacturer subsidy thing doesn't hold water.

Last edited:

SoonerAviator

Final Approach

- Joined

- Jul 21, 2014

- Messages

- 9,454

- Location

- Broken Arrow, OK

- Display Name

Display name:

SoonerAviator

This whole thing is why they need a "certified - owner maintained" category. At a certain point, the "certified parts" on a 50yr old aircraft is ridiculous. I don't buy a 1970 Chevelle and expect that every last bolt and contact switch is an OEM certified part. Obviously the consequences can be a bit more dire in an aircraft, but I'd take my chances that a door hinge or flap guide will be just as robust in the aftermarket than whatever exorbitant cost Cessna/Piper/etc. want to charge. Leave the more critical components to the certified group, leave alternators and accessory belts to the owner to decide.

Doc Holliday

En-Route

This whole thing is why they need a "certified - owner maintained" category.

We've watched as GA aircraft have declined maintenance wise with the "$200 annuals", so the owner maintained category will push a lot of these flying junk piles into further disrepair.

If they do come out with the owner maintained category, they will need a cockpit warning placard similar to E/AB.

- Joined

- Jun 7, 2008

- Messages

- 23,115

- Display Name

Display name:

Bob Noel

One possible result is that some of these older aircraft might get better parts if the owner doesn't have to pay $900 for a $1 switch.

Of course, one challenge is to know when an off-the-shelf item truly meets the requirements for installation in an aircraft.

Home Depot and Lowes sells things like water heaters that have the same model number as the stuff available at plumbing supply houses, but they are not the same quality.

Of course, one challenge is to know when an off-the-shelf item truly meets the requirements for installation in an aircraft.

Home Depot and Lowes sells things like water heaters that have the same model number as the stuff available at plumbing supply houses, but they are not the same quality.

SoonerAviator

Final Approach

- Joined

- Jul 21, 2014

- Messages

- 9,454

- Location

- Broken Arrow, OK

- Display Name

Display name:

SoonerAviator

Well, you can have flying junk piles that are "certified", or you could have perfectly fine flying aircraft that are "owner-maintained" that might otherwise be collecting dust because of a $1,500 NLA part that could have been bought for $150. I would assume there would be some sort of disclaimer placard, but that's pretty trivial. Tons of Experimentals aren't falling out of the sky because they use NAPA starters or non-certified LED position lights.We've watched as GA aircraft have declined maintenance wise with the "$200 annuals", so the owner maintained category will push a lot of these flying junk piles into further disrepair.

If they do come out with the owner maintained category, they will need a cockpit warning placard similar to E/AB.

Last edited:

And the other 10,000 parts of the airframe, engine and avionics? Many if not most of which cost more than $400? If I grant you a nickel per part, per day, that's $500/day cost of ownership -- $180,000 per year.A $400 part that should last 20+ years is a nickel a day.

View attachment 128802

Thanks for making the point, even if unintentionally.