George Mohr

Line Up and Wait

Hi all,

I have a 89 Warrior/Cadet with an O-320-D3G. It currently has 1800 SMOH with a much newer top end, and is running very sweetly. So this question is more of a hypothetical. For reference, the airplane is in really nice shape. 3,000 hours or so TTAF, great paint, good interior, well equipped with a 430W, S-Tec 20 AP, electric pitch trim. I plan on keeping it.

The history of this engine is rather long. Currently the engine has 10,200 hours TT in the logs (not the original engine in this airframe). It has been through at least 3 major overhauls to date (possibly more, my logs only go back to around 4,100 hours TTE, but lets assume that's right). There's no indication that the crank or case has ever been replaced, but it's hard to say for sure, lets assume not. I know the cam was reground once (at least).

Ok so then, fast forward (hopefully many hours) and it's time for my next major overhaul. Do I...

1) Get a big name engine shop O/H

2) Get a Lycoming O/H

3) or, get a Lycoming Rebuilt with a zero time logbook

That, my friends, is the question. Bring on the opinions!

Thanks in advance,

George

I have a 89 Warrior/Cadet with an O-320-D3G. It currently has 1800 SMOH with a much newer top end, and is running very sweetly. So this question is more of a hypothetical. For reference, the airplane is in really nice shape. 3,000 hours or so TTAF, great paint, good interior, well equipped with a 430W, S-Tec 20 AP, electric pitch trim. I plan on keeping it.

The history of this engine is rather long. Currently the engine has 10,200 hours TT in the logs (not the original engine in this airframe). It has been through at least 3 major overhauls to date (possibly more, my logs only go back to around 4,100 hours TTE, but lets assume that's right). There's no indication that the crank or case has ever been replaced, but it's hard to say for sure, lets assume not. I know the cam was reground once (at least).

Ok so then, fast forward (hopefully many hours) and it's time for my next major overhaul. Do I...

1) Get a big name engine shop O/H

2) Get a Lycoming O/H

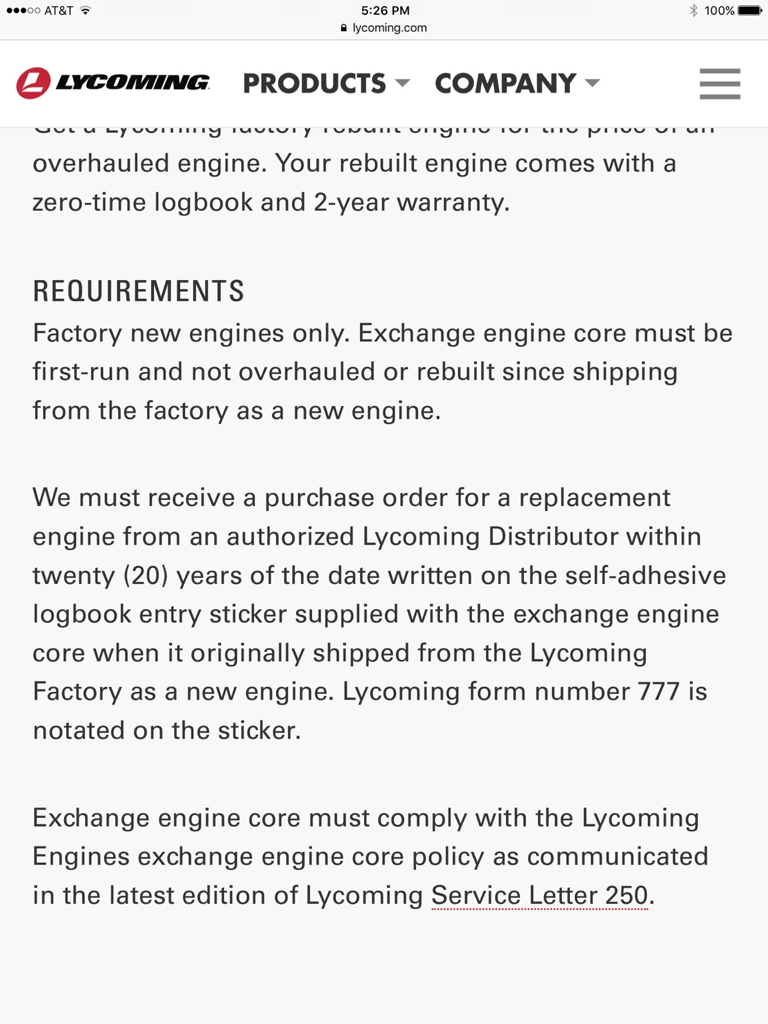

3) or, get a Lycoming Rebuilt with a zero time logbook

That, my friends, is the question. Bring on the opinions!

Thanks in advance,

George