wabower

Touchdown! Greaser!

- Joined

- Sep 1, 2008

- Messages

- 12,013

- Display Name

Display name:

Wayne

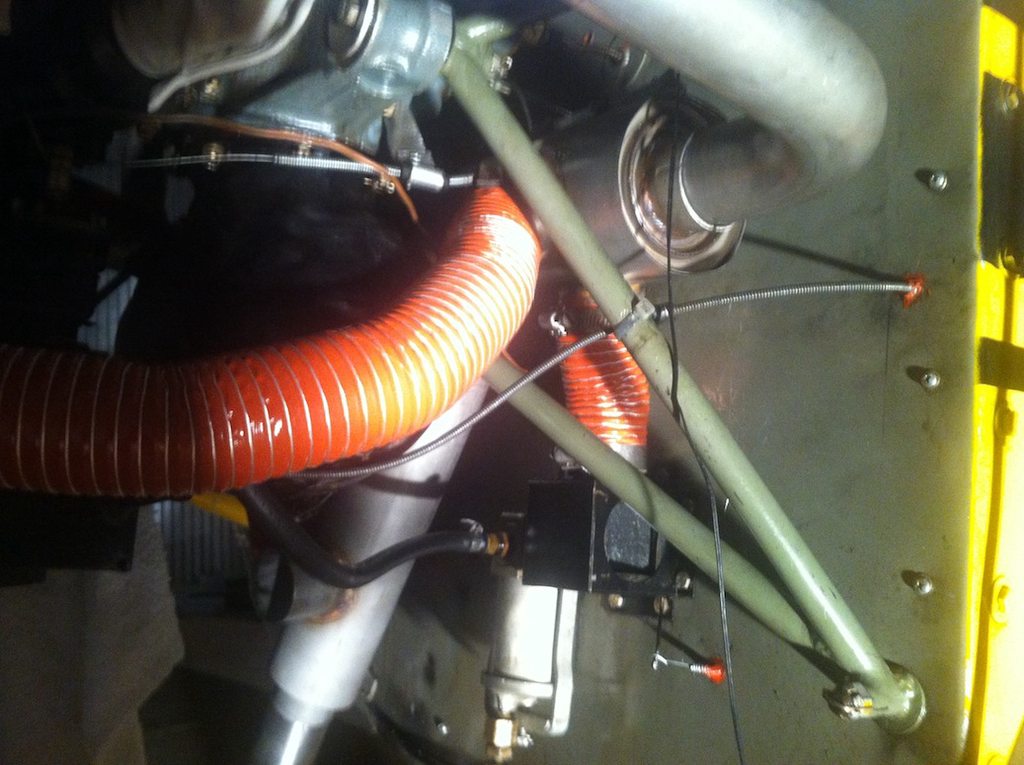

I found that angled hemostats were the best tool for working the scat over the duct. The low profile of the jaws combined with the ability to grip and tug lightly and then move, re-grip and do it again, and the ability to remove my fingers from the loops and move the tool without releasing its grip made the difference for part of the circumference. Real mechanics may have a better tool for this stuff.

Leave the white string on, place a piece of masking tape over it to hold it in place until you get a clamp over it. always capture the wire under the clamp. or it will move and ruin the tube.

.

.