Captain

Final Approach

So I had my first engine failure in just over 10,000 hours of flying the other night. We were enroute to KSUA and at FL270, going over 330 kts in cruise when it happened. I ended up diverting to KPBI for longer runways and better crash rescue services. I did declare an emergency.

A little background. A P180 has a power lever and a condition lever for each PT6 engine. They are both linked to the fuel control unit and propeller governor through linkages and use a bit of PFM to operate and control the engine. Basically, in flight, the power lever controls fuel to the engine and the condition lever controls prop pitch. That changes a bit on the ground and for start but that doesn't really apply here except the condition lever is also the fuel cutoff in the bottom detent.

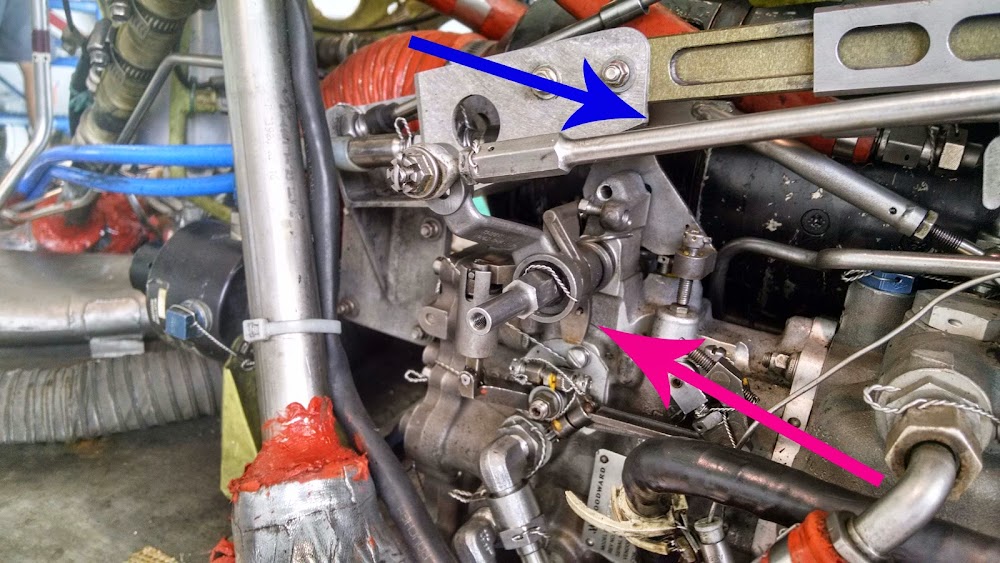

I've seen a cell phone video the mechanic took the following day and it's pretty obvious what happened. The linkage from the power lever became detached to the FCU.

So, while flying in cruise the right engine just accelerated to max power, over the normal cruise torque limit. The plane yawed firmly to the left and I immediately looked to the engine gauges to see the right engine over torqued. I pulled the right power lever back to lower the torque and that had no effect even going to the stop. So with the power lever all the way back at idle and the engine still in an over torque I was forced to pull the condition lever back to cutoff.

That's when the 'dead foot dead engine' saying went through my head...but wait..my left foot is dead. That's odd. I'm about to pull the right condition lever to cut off and my left foot is dead. I looked again at the stack and confirmed...'yup, it's the right engine' I said to myself and pulled it back to cutoff.

The right engine quit when the fuel was cut off and it went to feather. After that everything was as you'd expect. We continued and landed in PBI as uneventfully as you could expect having an engine failure. Talked to the Fire Rescue folks (nice guys and I've even taken my boys to their facility for a tour and a ride in the Dragon), gave some info to the airport manager rep and that was that.

Thought I'd pass this along as a possible alternative scenario to what we have ingrained in us during our ME training.

A little background. A P180 has a power lever and a condition lever for each PT6 engine. They are both linked to the fuel control unit and propeller governor through linkages and use a bit of PFM to operate and control the engine. Basically, in flight, the power lever controls fuel to the engine and the condition lever controls prop pitch. That changes a bit on the ground and for start but that doesn't really apply here except the condition lever is also the fuel cutoff in the bottom detent.

I've seen a cell phone video the mechanic took the following day and it's pretty obvious what happened. The linkage from the power lever became detached to the FCU.

So, while flying in cruise the right engine just accelerated to max power, over the normal cruise torque limit. The plane yawed firmly to the left and I immediately looked to the engine gauges to see the right engine over torqued. I pulled the right power lever back to lower the torque and that had no effect even going to the stop. So with the power lever all the way back at idle and the engine still in an over torque I was forced to pull the condition lever back to cutoff.

That's when the 'dead foot dead engine' saying went through my head...but wait..my left foot is dead. That's odd. I'm about to pull the right condition lever to cut off and my left foot is dead. I looked again at the stack and confirmed...'yup, it's the right engine' I said to myself and pulled it back to cutoff.

The right engine quit when the fuel was cut off and it went to feather. After that everything was as you'd expect. We continued and landed in PBI as uneventfully as you could expect having an engine failure. Talked to the Fire Rescue folks (nice guys and I've even taken my boys to their facility for a tour and a ride in the Dragon), gave some info to the airport manager rep and that was that.

Thought I'd pass this along as a possible alternative scenario to what we have ingrained in us during our ME training.

Last edited: