You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Horizontally Opposed Engines...

- Thread starter cleared4theoption

- Start date

kgruber

Final Approach

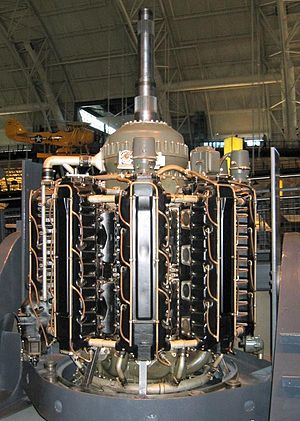

Now here's an ENGINE

PWA R4360. 28 cylinders, 7 magneto's, 56 spark plugs

Used in the Corsair among others.

Here's another:

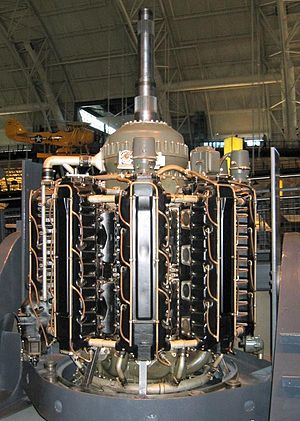

Lycoming R7755

36 cylinder 7755 CU IN

Dan Thomas

Touchdown! Greaser!

- Joined

- Jun 16, 2008

- Messages

- 10,754

- Display Name

Display name:

Dan Thomas

Lycoming R7755

36 cylinder 7755 CU IN

That's the XR-7755. It never got past the experimental stage to certification. The advent of the jets killed it.

Dan

Now here's an ENGINE

PWA R4360. 28 cylinders, 7 magneto's, 56 spark plugs

Used in the Corsair among others.

Negative sir, the Corsair used an R-2800 and the Super Corsair used an R-3350, both 2 row engines. The 4360 was the B-36 engine aka 'Corncob'.

X3 Skier

En-Route

Negative sir, the Corsair used an R-2800 and the Super Corsair used an R-3350, both 2 row engines. The 4360 was the B-36 engine aka 'Corncob'.

Correct and the Operational Corsairs did in fact use the R2800 and R-3350 but IIRC the F2G which was an late variant from Goodyear and never produced in any quantity (USN ordered some 400 near the end of the war) was designed around the R4360. It was a handful and replaced by the Bearcat before the age of jets.

Here's a clip from vimneo of a R4360 belching to life.http://vimeo.com/16117810

Should have been clearer about which Corsair.:wink2:

I had a friend who passed away a few years ago who was a Mechanic on the B-36. He had a special place in hell for a pilot who did not follow shut down procedures for the 4360 and resulted in having to replace the spark plugs on all six engines. Another friend flew the C-124 powered by the 4360 and considers himself lucky a) not to be Deaf or b) able to hold a coffee cup with one hand.

Cheers

X3 Skier

En-Route

I had always understood that if God had wanted mankind to fly behind horizontally opposed engines, Pratt & Whitney would have made engines that way.

Nothing like the sound of a good BIG Radial roaring to life but I suppose a Merlin will do in a pinch.

Nothing like the sound of a good BIG Radial roaring to life but I suppose a Merlin will do in a pinch.One of the best mementos I got on retiring as a USAF Engineer was a belt buckle with the "Dependable Engines" Eagle Medallion PWA puts on all their engines. It was interesting when I was working the F100 Engine program, how all the gearboxes were missing that Medallion about a day after they arrived on base.

Cheers

Ken Ibold

Final Approach

- Joined

- Feb 21, 2005

- Messages

- 5,888

- Location

- Jacksonville, Florida

- Display Name

Display name:

Ken Ibold

To say nothing of Dr. Porsche's follow-on designs.The Volkswagen Beetle was first produced in 1938. With a horizontally-opposed boxer engine. They did that for 65 years.

Capt. Geoffrey Thorpe

Touchdown! Greaser!

- Joined

- Jun 7, 2008

- Messages

- 15,626

- Location

- DXO124009

- Display Name

Display name:

Light and Sporty Guy

This is what I've heard, but you would think an inline or V would be better for streamlining...however I'm all the companies already researched and tested that theory in the 40s

A V fits better if you have to squeeze it in between the front wheels of a car, but for a two person wide airplane there is less advantage to the narrow engine since you are making a wide airplane anyhow. V's and inline were popular for narrow (one person wide) aircraft applications - particularly if you needed a big pile of cubic inches in a narrow package (fighter aircraft).

Plus, unless you invert it, a V (or inline) configuration puts the crankshaft closer to the ground which means a shorter, less efficient prop (or longer heavier landing gear). Inverting the engine was common with in-line or V engines to get the crank up higher, but then you have all of the lubrication issues to deal with - it can be done, but a flat engine is just easier.

Flat engines package well in the typical G.A. aircraft.