Domenick

Pattern Altitude

- Joined

- Sep 11, 2019

- Messages

- 1,826

- Display Name

Display name:

Domenick

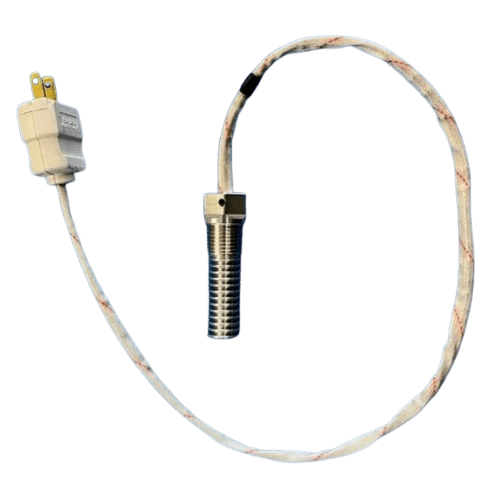

No Hassle Engine Pre-Heater - AntiSplatAero

“No Hassle Engine Pre-Heater” is our newest specialty accessory, developed specifically for use in most Lycoming equipped aircraft. After experiencing first-hand, the difficulties and frustrations involved when trying to address cold start, and engine warm-up issues. Numerous conversations with...

antisplataero.com

antisplataero.com