I will appreciate any pointers. I have no problem retracting likely due to spring assist, but will sound like it is labouring extending the flaps. It will trip the breaker doing this. The flap motor becomes very hot to the touch after 2 cycles. I am able to freely turn the worm mechanism by hand by rotating the shaft of the motor making me think it is not binding. I inspected and lubricated all rollers. Battery voltage is a bit low on the ground (11.9), but in the air the alternator should give enough. Can I test the motor somehow, is it the possible culprit? Thanks all!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Comanche flap operation popping breaker

- Thread starter Phil007

- Start date

Doc Holliday

En-Route

What does your mechanic say?

Kenny Phillips

Final Approach

- Joined

- Jul 29, 2018

- Messages

- 5,499

- Display Name

Display name:

Kenny Phillips

At 11.9 volts, you need a battery; that's a volt or so low. Could be a weak cell, which generally ends with a dead cell. Start with a new battery.I will appreciate any pointers. I have no problem retracting likely due to spring assist, but will sound like it is labouring extending the flaps. It will trip the breaker doing this. The flap motor becomes very hot to the touch after 2 cycles. I am able to freely turn the worm mechanism by hand by rotating the shaft of the motor making me think it is not binding. I inspected and lubricated all rollers. Battery voltage is a bit low on the ground (11.9), but in the air the alternator should give enough. Can I test the motor somehow, is it the possible culprit? Thanks all!

Dan Thomas

Touchdown! Greaser!

- Joined

- Jun 16, 2008

- Messages

- 10,750

- Display Name

Display name:

Dan Thomas

Might be the battery, might be a bad alternator or misadjusted regulator. Best to do some troubleshooting of the charging system first.

A low battery means a low flap motor RPM, and that means a higher current draw due to reduced inductive reactance in the motor. That shouldn't pop the breaker so easily, but I bet that breaker is old, meaning its contacts are oxidized and have resistance, and that resistance adds to the heating of the thermal strip in the breaker that pops it.

Maintenance is often far behind, and incorrect to boot. From the Comanche service manual:

So when was the flap transmission apart, cleaned and relubed last? Did it get the right lube? Are all the system pulleys turning freely, or are they frozen up as most old pulleys are if they're not inspected?

Using grease or oil on the flap tracks attracts dust and grit and leads to wear and binding. The specified lube might be a dry silicone or graphite lube that stays clean.

Piper wanted that transmission opened and lubed annually or every 500 hours, whichever came first. Annually is a bit of overkill, I think, but I'd bet that most haven't been out in 25 years or more. I know of a twin Comanche that had a gear-up landing because the gear transmission seized up from lack of maintenance.

A low battery means a low flap motor RPM, and that means a higher current draw due to reduced inductive reactance in the motor. That shouldn't pop the breaker so easily, but I bet that breaker is old, meaning its contacts are oxidized and have resistance, and that resistance adds to the heating of the thermal strip in the breaker that pops it.

Maintenance is often far behind, and incorrect to boot. From the Comanche service manual:

So when was the flap transmission apart, cleaned and relubed last? Did it get the right lube? Are all the system pulleys turning freely, or are they frozen up as most old pulleys are if they're not inspected?

Using grease or oil on the flap tracks attracts dust and grit and leads to wear and binding. The specified lube might be a dry silicone or graphite lube that stays clean.

Piper wanted that transmission opened and lubed annually or every 500 hours, whichever came first. Annually is a bit of overkill, I think, but I'd bet that most haven't been out in 25 years or more. I know of a twin Comanche that had a gear-up landing because the gear transmission seized up from lack of maintenance.

Chip Sylverne

Final Approach

- Joined

- Jun 17, 2006

- Messages

- 5,891

- Display Name

Display name:

Quit with the negative waves, man.

There's a lot less stress on the flap motor and trans than on the gear equipment, so I would doubt it's trans maintenance, though possible. I would dig into the motor, check that the commutator brushes are good, that the armature doesn't look or smell burnt, that the armature shaft bushings are square and the case bolts are tight. I had this same thing happen, turned out the motor shaft was intermittantly binding in the motor housing because the case bolts weren't tight.

You can test the motor by checking the resistance of the field windings, and by checking each contractor of the commutator to see there are no shorts to ground. But really, a good look for black windings and a good sniff for a burnt smell w I'll tell you if it's good or bad. Might also take a good look at the knife splices to see they are tight and clean.

Matt Kurke at Comanchegear.com is a good source for motors and info.

How much amp draw is there when the motor is in use?

You can test the motor by checking the resistance of the field windings, and by checking each contractor of the commutator to see there are no shorts to ground. But really, a good look for black windings and a good sniff for a burnt smell w I'll tell you if it's good or bad. Might also take a good look at the knife splices to see they are tight and clean.

Matt Kurke at Comanchegear.com is a good source for motors and info.

How much amp draw is there when the motor is in use?

My take on gear-up landings in a Commanche is pilot error. During Annuals; I would generally have the pilot in the seat doing the transmission disconnect and extension procedure. Many would appear “ lost”.

There is a procedure using a torque wrench to check for friction in the landing gear system. I’m unaware of this for the flaps though.

A bud was going missed in a Twinky and was under the hood and raising flaps.

A rapidly increasing roll developed. “ Undo what you just did” worked. On flap was binding and airspeed and the spring were not enough to retract. Scary.

There is a procedure using a torque wrench to check for friction in the landing gear system. I’m unaware of this for the flaps though.

A bud was going missed in a Twinky and was under the hood and raising flaps.

A rapidly increasing roll developed. “ Undo what you just did” worked. On flap was binding and airspeed and the spring were not enough to retract. Scary.

3393RP

En-Route

- Joined

- Oct 8, 2012

- Messages

- 4,057

- Display Name

Display name:

3393RP

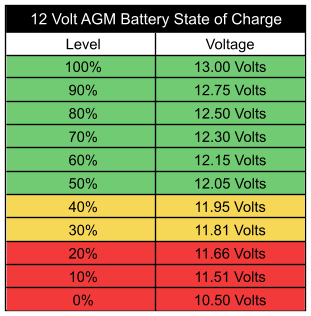

An AGM battery's measured 11.9 open circuit voltage indicates a 40% state of charge. Before proceeding with troubleshooting procedures on the flap motors outlined by other posters, disconnect the battery from the aircraft's electrical system and charge it to 100%.

Do not attempt to charge the battery with a Battery Minder. It cannot provide the needed current. Use a charger capable of a minimum of 10 amps output, and use the three step method outlined on the website to obtain a 100% charge. I have posted a link to the US Battery website and the pertinent section below.

You may discover the problem was simply an undercharged battery. Read and understand the steps required, charge the battery, and find out why the battery became so severely discharged. Fix the problem, then you can proceed to troubleshooting the flap issue.

As part of U.S. Battery’s charging recommendations, charging methods are categorized into three basic methodologies based on the number of charge stages used in the charging process. It should be noted that the basic charge stages should result in a fully charged battery at the end of the final charge stage.

Using this criterion, float charging, maintenance charging, and equalization charging are not considered to be one of the basic charge stages. These basic charge stage methodologies can be defined as follows:

Three-Stage Charging – Charging using bulk charge, absorption charge, and finish charge (usually constant current – constant voltage – constant current).

Two-Stage Charging – Charging using bulk charge and absorption charge only (usually constant current – constant voltage).

Single-Stage (Ferroresonant) Charging – Charging using a single-stage charge with tapering current and voltage.

Last edited:

Chip Sylverne

Final Approach

- Joined

- Jun 17, 2006

- Messages

- 5,891

- Display Name

Display name:

Quit with the negative waves, man.

My take on gear-up landings in a Commanche is pilot error. During Annuals; I would generally have the pilot in the seat doing the transmission disconnect and extension procedure. Many would appear “ lost”.

There is a procedure using a torque wrench to check for friction in the landing gear system. I’m unaware of this for the flaps though.

A bud was going missed in a Twinky and was under the hood and raising flaps.

A rapidly increasing roll developed. “ Undo what you just did” worked. On flap was binding and airspeed and the spring were not enough to retract. Scary.

I know of a couple instances where the pilot just didn't slow the airplane enough to allow manual gear extension. You have to be 100mph or less or the wind keeps the gear in the wells. One guy flew around pulling on the handle for all he was worth for an hour, finally gave up and resigned himself to a gear up. Coming down final he slowed it to approach speed and the gear fell down all by itself!

The asymmetric flaps thing does get your attention. Haven't experienced it firsthand, but know someone who has. Every annual all the pulleys and step-back gets the full LPS 2 treatment. Forgetting to reset the trim to take-off gets your attention too.

mandm

Pattern Altitude

How’s the amp meter reading in flight? If high, turn off other non necessary items, then try again. I’ve been more diligent about slowing the airplane down more before dropping gear and flaps. (If one north of flaps calls for 110, I think to get airspeed closer to 100 first, gear down really helps slow it down too)

Kristin

Pattern Altitude

- Joined

- Dec 1, 2013

- Messages

- 1,610

- Location

- Twin Cities

- Display Name

Display name:

Kristin (The Aviatrix)

My take on gear-up landings in a Commanche is pilot error. During Annuals; I would generally have the pilot in the seat doing the transmission disconnect and extension procedure. Many would appear “ lost”.

There is a procedure using a torque wrench to check for friction in the landing gear system. I’m unaware of this for the flaps though.

A bud was going missed in a Twinky and was under the hood and raising flaps.

A rapidly increasing roll developed. “ Undo what you just did” worked. On flap was binding and airspeed and the spring were not enough to retract. Scary.

For pure gear up landings, i.e. the gear never came down at all, you are correct. Almost always pilot error. I have heard of two incidences where witnesses saw the gear go partly up and down repeatedly and learned later that the pilot was attempting to pump down the gear, not understanding how the system worked or bothering to read the directions.

However, a large portion of the Comanche belly slides are actually gear collapses, and most of those are maintenance errors. I inspect a few dozen Comanche landing gear systems annually and see a lot of scary stuff.

Kristin

Pattern Altitude

- Joined

- Dec 1, 2013

- Messages

- 1,610

- Location

- Twin Cities

- Display Name

Display name:

Kristin (The Aviatrix)

I will appreciate any pointers. I have no problem retracting likely due to spring assist, but will sound like it is labouring extending the flaps. It will trip the breaker doing this. The flap motor becomes very hot to the touch after 2 cycles. I am able to freely turn the worm mechanism by hand by rotating the shaft of the motor making me think it is not binding. I inspected and lubricated all rollers. Battery voltage is a bit low on the ground (11.9), but in the air the alternator should give enough. Can I test the motor somehow, is it the possible culprit? Thanks all!

The transmission extends the flaps. Air loads and springs retract them. If the motor is getting that hot on the ground, you either have significant resistance in the system, which I think unlikely, or the transmission is going south on you. Webco in Newton, KS, or ComancheGear, in Naples, FL can provide replacement units or overhaul the one you have. Have your mechanic check the system out and assuming my guess is correct, these two are good resources.

I just want to provide some feedback. I inspected the rollers of one flap. They were the upgraded nylon bushings, and they were dry lubed. Once the flaps are engaged fast 0°, I was able to test the resistance by pushing on the flaps down by hand in order to extend them. I did not feel any significant resistance, just the spring giving me the natural resistance. I then removed the motor, gearbox and accentuator, and upon opening the motor, got a distinct smell of burning electricity. I did not see anything obviously wrong in the motor, and operation on the ground pulled approximately 4 A. The whole flap assembly was easily rotated by hand, confirming that it’s not binding anywhere.

Our AME will be involved from this point forth, and I will order a motor from comanchegear. I am waiting for a response from them now.

I appreciate all the useful feedback. Greetings from the great white north.

Our AME will be involved from this point forth, and I will order a motor from comanchegear. I am waiting for a response from them now.

I appreciate all the useful feedback. Greetings from the great white north.

midcap

Pattern Altitude

somthing is binding up and causing that motor to get hot.

Possibly its the bearings on the armature of the motor itself?

Possibly its the bearings on the armature of the motor itself?

Chip Sylverne

Final Approach

- Joined

- Jun 17, 2006

- Messages

- 5,891

- Display Name

Display name:

Quit with the negative waves, man.

somthing is binding up and causing that motor to get hot.

Possibly its the bearings on the armature of the motor itself?

Not necessarily. The motor is 60 years old, with who knows how many cycles. Mag wire breaks down, gets thin with heat and vibration, resistance changes, shorts happen.

It's a good opportunity to service the trans, but I wouldn't count on finding a problem unless the brake is dragging or the like.

midcap

Pattern Altitude

yeah thats true.Not necessarily. The motor is 60 years old, with who knows how many cycles. Mag wire breaks down, gets thin with heat and vibration, resistance changes, shorts happen.

It's a good opportunity to service the trans, but I wouldn't count on finding a problem unless the brake is dragging or the like.