You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Flying airplane with missing cowl flap

- Thread starter Supereri

- Start date

Horsheim in AU makes an STC for a fixed cowl flap for the 182. It replaces the movable cowl flaps with a fixed version. The people that have them seem to like them. Lowers CHTs. I think it may affect TAS a bit.

https://horshamaviation.com.au/stcs-horsham-aviation/

https://horshamaviation.com.au/stcs-horsham-aviation/

Dan Thomas

Touchdown! Greaser!

- Joined

- Jun 16, 2008

- Messages

- 10,744

- Display Name

Display name:

Dan Thomas

Commonly heat treated if there is as much forming as with that cowl flap. There is no way you could stretch aluminum as much as that inside layer is without tearing it unless the aluminum was dead-soft 1100, and then its strength would be uselessly low.Are you sure a low stress part like this is heat treated? Is it so marked? Also it might be made of fiberglass with a field approval.

Making it of fiberglass? The hassles and costs of field approval would easily outweigh the hassles and costs of just buying a used one, even a ratty one, and repairing it. Easily. All of the alternate suggestions here on this thread would be like that.

Last edited:

Dan Thomas

Touchdown! Greaser!

- Joined

- Jun 16, 2008

- Messages

- 10,744

- Display Name

Display name:

Dan Thomas

There are certifications required for the equipment and personnel that heat-treat aircraft parts. That makes such places rare. The size of the part has no bearing on it.Looks to me it could be replicated with a wooden buck and a bench brake. Surely there is a place to have something that small heat treated.

I worked for a time in a large-aircraft shop. We had the required oven for doing it, but no one certified to do it, so the equipment just sat there. The stuff we made had to be sent off somewhere to a shop that had everything and everyone required.

Dan Thomas

Touchdown! Greaser!

- Joined

- Jun 16, 2008

- Messages

- 10,744

- Display Name

Display name:

Dan Thomas

Maxnr

Line Up and Wait

Just asking. How about a ferry permit? If necessary, at reduced power. I don't know how far you have to go. Many of us have used a permit to get to the nearest maint base. I'm not talking trans-continental of course.So I’m thinking of buying a Cessna 182 that recently had a cowl flap go missing. The seller is looking for one now, but hasn’t found one yet. He’s talking about discounting the airplane the cost of a new one. My concern is the airplane legal to fly missing one cowl flap? If I buy the aircraft can I get it home across the country missing it?

Last edited:

Supereri

Pre-takeoff checklist

- Joined

- Apr 5, 2022

- Messages

- 114

- Display Name

Display name:

Supereri

Horsheim in AU makes an STC for a fixed cowl flap for the 182. It replaces the movable cowl flaps with a fixed version. The people that have them seem to like them. Lowers CHTs. I think it may affect TAS a bit.

https://horshamaviation.com.au/stcs-horsham-aviation/

I had seen these as well and mentioned it to the seller. Looks like he's going this direction. Living in Phoenix AZ I think these would be good if I end up purchasing the plane. MY only concern is the engine getting too cold if I travel somewhere during the winter.

FYI: there are no distance limitations on ferry permits. The reason for the permit will usually dictate how far and where you can go.I'm not talking trans-continental of course.

martym

Pre-takeoff checklist

He must not be looking too hard. Truckloads of stuff like that at salvage yards.So I’m thinking of buying a Cessna 182 that recently had a cowl flap go missing. The seller is looking for one now, but hasn’t found one yet.

Yes, you can ferry the plane on a ferry permit. Otherwise it's a non issue.

Maxnr

Line Up and Wait

Noted. There are practical reasons why you may limit the flight to the minimum. The ones that I flew were usually in a "sick" aircraft and were to the nearest maint facility. I have seen all kinds of flights on a ferry permit that make me do a double take. Example, A Sikorsky S-76 looses an engine and lands OK on an oil platform. They stripped about all loose gear and left a single life raft. Defueled it to the minimum for a 40 mile flight. Detailed a 160 lb pilot to bring her in. T.O. was early AM with a little wind. And he made an OEI take off. No sweat. Some that I did were a learning experience. I couldn't retract the gear. I forget why. I got on the phone and called for a replacement A/C. I had a load waiting for a scheduled flight. Help showed up with only an A&P with a ball point. I got on the phone. The A&P instead signed of his part of the Minimum Equipment List (MEL) requirements and pinned the gear. I then did a one hour twenty minute flight in a mere two hours and "stiff legged" it home. No Ferry permit needed. Who knew you could carry paying passengers in an A/C with the gear stuck down.FYI: there are no distance limitations on ferry permits. The reason for the permit will usually dictate how far and where you can go.

One of the joys of Part 135, you get to make your own rules and get them approved! Not as good as Part 121 but it works.No Ferry permit needed. Who knew you could carry paying passengers in an A/C with the gear stuck down.

Maxnr

Line Up and Wait

As we know, 135 (&121) is allowed to make rules MORE stringent but not less than the FARS.One of the joys of Part 135, you get to make your own rules and get them approved! Not as good as Part 121 but it works.

I had a copilot who was also a freelance A&P when he was off schedule. He told me of getting called out one night for a 121 air carrier that had a minor glitch and MELed it. Their maint was not available that night. The PIC followed the MEL to the letter, but the FO dug in his heels and would not depart till an AI signed it off. Phone calls were made and the FO accepted an A&P sign of. My Bud had not "seen" a Boeing till that night. Actually, the PIC can sign it off.

camorton

Pre-takeoff checklist

- Joined

- Nov 29, 2018

- Messages

- 217

- Display Name

Display name:

Craig Morton

Losing a cowl flap is unfortunately not so uncommon. The hinges wear due to vibration and fail in-flight. Lots of tips and tricks out there among Cessna owners to maintain and increase the life-span of these parts. Not so easy to replace if lost. Cessna/Textron does not have the older ones in stock anymore, and you'd probably pass out if you saw the price anyway. You can find LH ones on eBay, but chances are you need a RH one since those are the ones that go missing most of the time (they are right behind the exhaust stack and get beat-up by the power pulses). Much harder to find at the salvage yards, but may be available. It would be a VERY difficult part to owner-produce, IMHO. The STC for the fixed flap would be the cheapest alternative by far, but unless you're building a dedicated back-country plane, I'd try hard to keep it original. I'd expect a discount of at least $5K for a plane missing this part. No joke. You might get lucky and find one, but you might not.

C.

C.

Whitney

Ejection Handle Pulled

Sounds like a lucrative business for someone to get into, making them.

The real money is in fabricating/rebuilding the entire cowlings... along with wings and tail feathers which I think about doing at least once a year until I get back to my senses.Sounds like a lucrative business for someone to get into, making them.

Dave Theisen

En-Route

Apparently, these things are strewn all over the countryside. You could just go on an American Pickers style hunt for one.

Whitney

Ejection Handle Pulled

Shouldn't the annuals detect a part so bad its about to fall off?

Who is doing these annuals, big birds blind great grandfather.

Who is doing these annuals, big birds blind great grandfather.

3393RP

En-Route

- Joined

- Oct 8, 2012

- Messages

- 4,048

- Display Name

Display name:

3393RP

Shouldn't the annuals detect a part so bad its about to fall off?

Who is doing these annuals, big birds blind great grandfather.

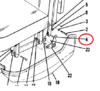

Based on the condition of the one pictured above in post #18, I hope it isn't considered airworthy. That part needed repairs long before that photo was taken.

The red RTV smeared on the hinge is probably indicative of the level of maintenance expertise the aircraft it was attached to has received.

Whitney

Ejection Handle Pulled

Based on the condition of the one pictured above in post #18, I hope it isn't considered airworthy. That part needed repairs long before that photo was taken.

The red RTV smeared on the hinge is probably indicative of the level of maintenance expertise the aircraft it was attached to has received.

That's my point.

What falls off next?

Rudder, elevator, aileron, flap?

Recently there was a thread complaining about the cost of annuals. I commented that I thought that was actually far too cheap, and probably of low quality.

Cheap annuals, garner poor quality.

I think that my cheapest annual on my 180 since buying it 14 years ago, was about 3,000 American dollars. But I like my plane to remain maintained. Even a $9,000 annual really isn't expensive, if it means things were caught, and repaired.

Mtns2Skies

Final Approach

- Joined

- Jul 12, 2008

- Messages

- 5,618

- Display Name

Display name:

Mtns2Skies

Based on the condition of the one pictured above in post #18, I hope it isn't considered airworthy. That part needed repairs long before that photo was taken.

The red RTV smeared on the hinge is probably indicative of the level of maintenance expertise the aircraft it was attached to has received.

The RTV is often added to keep the hinge from vibrating and breaking. In other words, it was likely a preventive measure.

Whitney

Ejection Handle Pulled

Oh calm down:

https://www.univair.com/cessna/part...MkXrT_9wApNgBd3tHKAmdNFhbHKyisoYaAl9pEALw_wcB

https://selkirk-aviation.com/wp-content/uploads/2016/10/Individualcowlingpieces2.pdf

https://www.ebay.com/itm/142888576741?chn=ps&_trkparms=ispr=1&amdata=enc:16ivOIwLXSZiaqCiJNz8nZw8&norover=1&mkevt=1&mkrid=711-117182-37290-0&mkcid=2&itemid=142888576741&targetid=1644837435803&device=c&mktype=&googleloc=9018923&poi=&campaignid=16743749222&mkgroupid=138744546207&rlsatarget=pla-1644837435803&abcId=9300842&merchantid=114729442&gclid=Cj0KCQjw2MWVBhCQARIsAIjbwoOs3h5mWCfURekI9XueoHNSAxrCobz8YYGC4w-aQLCRHGx1I4f3sOgaAs45EALw_wcB

$750 isn't even expensive.

The way some were talking I expected them to be $4,000, which is why I suggested getting one made.

There have been a number of threads on mx costs with several forum stalwarts advocating the benefits of a 20 minute/$200 annual inspections to the point of arguing their reasons. Unfortunately, you will find there are owners out there that specifically look for such "deals." And in my opinion that group is growing as the numbers of older APIAs fly west or retire with no replacements.Recently there was a thread complaining about the cost of annuals. I commented that I thought that was actually far too cheap, and probably of low quality.

Whitney

Ejection Handle Pulled

There have been a number of threads on mx costs with several forum stalwarts advocating the benefits of a 20 minute/$200 annual inspections to the point of arguing their reasons. Unfortunately, you will find there are owners out there that specifically look for such "deals." And in my opinion that group is growing as the numbers of older APIAs fly west or retire with no replacements.

I like them to go slow, really dig deep, find problems, and then fix it to at least as good as new. If they are finding nothing wrong on my 1976 antique, why not?

I would be questioning the hell out of a bug free $1500 annual.

3393RP

En-Route

- Joined

- Oct 8, 2012

- Messages

- 4,048

- Display Name

Display name:

3393RP

The RTV is often added to keep the hinge from vibrating and breaking. In other words, it was likely a preventive measure.

Which is exactly my point. If the hinge was worn enough to need goop to be smeared on it, replacement would have been the more conservative (and IMO proper) choice.

Which was exactly my point. If the hinge was worn enough to need goop to be smeared on it, replacement would have been the more conservative (and IMO proper) choice.

You don't understand. The RTV gets put on a new hinge to keep the vibration from wearing it out or cracking it. The cowl flap hinges on these aircraft are a common failure point so people do it proactively.

Dan Thomas

Touchdown! Greaser!

- Joined

- Jun 16, 2008

- Messages

- 10,744

- Display Name

Display name:

Dan Thomas

Losing a cowl flap is unfortunately not so uncommon. The hinges wear due to vibration and fail in-flight. Lots of tips and tricks out there among Cessna owners to maintain and increase the life-span of these parts.

There is one tip to avoid this sort of thing: Find a good mechanic and let him take his time and look at things thoroughly. One has to get down on the floor under the airplane and rattle the cowl flaps and see if there is wear on the hinge, see if the hinge's rivets are working loose, see if the actuator cables are still OK and if the clevis pin and the shockmount aren't worn out.

Stuff just isn't getting looked at, and that's because either the owner is too cheap to pay for better inspections, or the shop is afraid of losing the customer so keeps the inspection brief.

I find worn clevis pins in much worse places. One of them is in the infinitely-adjustable Cessna crew seats. The seat back angle is adjusted by a crank that turns a jackscrew that rotates a shaft that has a cam on either end that runs agains a couple of 3/16" clevis pins in the seat back arms. Those pins wear out. I have found them worn more than halfway through, ready to break. Imagine one pin, and then the other due to subsequent overloading, breaking just as the airplane leaves the runway on takeoff. The seat back falls back and the pilot reflexively pulls on the control horn to lift himself, stalling the airplane and crashing, all because nobody bothered to look at a couple of fifty-cent pins. It's gonna happen sooner or later.

Dan Thomas

Touchdown! Greaser!

- Joined

- Jun 16, 2008

- Messages

- 10,744

- Display Name

Display name:

Dan Thomas

One of those is fine if it fits the model the OP has. The first fits '56 to '58 airplanes. The second is for an H model (1965), and the last is for the 2001+ model. There were a lot of legacy 182s built between '59 and '65 and '66 to '96, and a lot of them have needed new cowl flaps, making them a little scarce. The shapes of these things changed over the years. Some didn't use piano hinges; they pivoted on a couple of bolts.Oh calm down:

Whitney

Ejection Handle Pulled

Which is exactly my point. If the hinge was worn enough to need goop to be smeared on it, replacement would have been the more conservative (and IMO proper) choice.

Amen!

If it's showing wear, fix it right.

Whitney

Ejection Handle Pulled

You don't understand. The RTV gets put on a new hinge to keep the vibration from wearing it out or cracking it. The cowl flap hinges on these aircraft are a common failure point so people do it proactively.

What a cheesy way of band aiding a problem. Why not keep an eye on it regularly, and when it has wear, replace the hinge. Coating it in goop so you cannot properly see it, to correctly inspect it, is not the right way.

If money is that tight, consider selling the plane, ownership is nice, but not mandatory. Maintenance really isn't that expensive. The way some people act, you would think that they were spending a million dollars a year on maintenance.

Planes are cheap!

Try the maintenance on a fleet of semi trucks, or for a farm and all its equipment, that is expensive!!!

Fertilizer alone costs multiple times more than my 180 is worth.

I guess that cheaping out on maintenance, is something that really makes me cringe.

Like the people who said replacing my spark plugs annually is a waste. Maybe for some they view it that way, to me its cheap maintenance. Plugs are cheap, not a grand apiece.

What a cheesy way of band aiding a problem. Why not keep an eye on it regularly, and when it has wear, replace the hinge. Coating it in goop so you cannot properly see it, to correctly inspect it, is not the right way.

If money is that tight, consider selling the plane, ownership is nice, but not mandatory. Maintenance really isn't that expensive. The way some people act, you would think that they were spending a million dollars a year on maintenance.

Planes are cheap!

Try the maintenance on a fleet of semi trucks, or for a farm and all its equipment, that is expensive!!!

Fertilizer alone costs multiple times more than my 180 is worth.

I guess that cheaping out on maintenance, is something that really makes me cringe.

Like the people who said replacing my spark plugs annually is a waste. Maybe for some they view it that way, to me its cheap maintenance. Plugs are cheap, not a grand apiece.

Why is it that you and the other guy think that silicone on the hinge as a preservation tactic believe that this equates to being cheap?

I’ve personally replaced enough cowl flap hinges to know that this is an area that is often neglected. I’m not going to throw stones at an owner who is trying to keep their hinges nice. (It seems to work BTW.)

3393RP

En-Route

- Joined

- Oct 8, 2012

- Messages

- 4,048

- Display Name

Display name:

3393RP

Why is it that you and the other guy think that silicone on the hinge as a preservation tactic believe that this equates to being cheap?

I’ve personally replaced enough cowl flap hinges to know that this is an area that is often neglected. I’m not going to throw stones at an owner who is trying to keep their hinges nice. (It seems to work BTW.)

The other guy is specifically discussing the cowl flap in post #18. Would you consider it an airworthy part?

That RTV wasn't placed on the hinge when it was new. Look at the fretting traces on the right hand end of the hinge and the condition of the hinge pin. Observe the wear on some of the rivets. I look at its overall appearance, and it's more than obvious the sealant is there to keep a worn out hinge from vibrating apart.

If it was on my aircraft, it would have been properly repaired several hundred hours ago.

Last edited:

The other guy is specifically discussing the cowl flap in post #18. Would you consider it an airworthy part?

Im not going to make an assessment without actually seeing the flap and hinge.

Whitney

Ejection Handle Pulled

The other guy is specifically discussing the cowl flap in post #18. Would you consider it an airworthy part?

That RTV wasn't placed on the hinge when it was new. Look at the fretting traces on the right hand end of the hinge and the condition of the hinge pin. I look at its overall appearance, and it's more than obvious the sealant is there to keep a worn out hinge from vibrating apart.

If it was on my aircraft, it would have been properly repaired several hundred hours ago.

Ditto.

Or try a little grease.

Wipe it off annually, inspect, and then reapply.

Coating a trashed part in goop, is not fixing it, just trying to hide the problem.

3393RP

En-Route

- Joined

- Oct 8, 2012

- Messages

- 4,048

- Display Name

Display name:

3393RP

Im not going to make an assessment without actually seeing the flap and hinge.

Sigh. I'm sorry if I appeared confrontational. Sometimes my internet forum exuberance overrides my normally filtered objective self.

You'll find that a number of owners think it does equate to a $1M when it comes to properly fixing their personal aircraft. It was this increasing nickel and dime BS that led me to performing owner-assistanted mx with my side business. This group wanted to fix things and keep inline with the regs.you would think that they were spending a million dollars a year on maintenance

Dan Thomas

Touchdown! Greaser!

- Joined

- Jun 16, 2008

- Messages

- 10,744

- Display Name

Display name:

Dan Thomas

Grease and oil attract dirt and grit and dust, and now we have abrasive grinding away in there, accelerating the wear by several times. They should be left absolutely dry, or lubed with dry graphite. Nothing more. I have replaced enough aileron hinges on Cessnas (piano hinges) that have been worn out by grit because they were oiled.Ditto.

Or try a little grease.

Wipe it off annually, inspect, and then reapply.

Coating a trashed part in goop, is not fixing it, just trying to hide the problem.

RTV is commonly used to damp movement and therefore wear. There's nothing wrong with it on cowl flap hinges, if those hinges aren't already shot. It's also sometimes used on engine cooling baffles to prevent fretting and wear.

I get a little annoyed at the opinions of pilots and owners who have no maintenance experience or training. They don't know how little they know.

PG is powdered graphite. Cessna specifies it for the reason I noted above. Cessna does not call for flap hinge lubrication of any sort in the 182 manual, unless the "all piano hinges" in the top diagram also refers to the cowl flap hinges.

Too many mechanics, and a lot of owners, love to go around the airplane and squirt oil on everything, not knowing the damage they're causing. One POAer squirts oil into his retractable gear microswitches, a perfect recipe for switch failure.

Maintenance manuals are priceless. I wish more people paid attention to them.

The red RTV smeared on the hinge

FYI: To add, using sealant as shown in #18 is common as a preventative measure to reduce wear. However, if the hinge is worn out under the RTV thats a different matter except that when it is worn out RTV won't last at that point. And given the RTV has clean lines and is intact my bet it was done as a preventative. We use similar methods on helicopters to keep things tight and reduce the smoke trails. Some measures are even approved and depending on how many times that area needs to be accessed RTV or proseal are the usual materials. So just because something appears out of place or is not in the book isn't always indicative of the over all maintenance condition of an aircraft. And I'm also not a fan of squirting oil and grease everywhere as it usually causes secondary issues as noted above.Coating a trashed part in goop, is not fixing it, just trying to hide the problem.

Dan Thomas

Touchdown! Greaser!

- Joined

- Jun 16, 2008

- Messages

- 10,744

- Display Name

Display name:

Dan Thomas

The RTV on the hinge would work well if it was applied with the flap open, then the flap closed halfway and left there to let the RTV cure. That way the cured RTV pulls the hinge halves together when it's wide open, and pushes them apart when it's closed, in both cases discouraging rattling and wear. Cowl flaps don't spend a lot of time halfway open. Not up here, anyway.FYI: To add, using sealant as shown in #18 is common as a preventative measure to reduce wear. However, if the hinge is worn out under the RTV thats a different matter except that when it is worn out RTV won't last at that point. And given the RTV has clean lines and is intact my bet it was done as a preventative. We use similar methods on helicopters to keep things tight and reduce the smoke trails. Some measures are even approved and depending on how many times that area needs to be accessed RTV or proseal are the usual materials. So just because something appears out of place or is not in the book isn't always indicative of the over all maintenance condition of an aircraft. And I'm also not a fan of squirting oil and grease everywhere as it usually causes secondary issues as noted above.

Whitney

Ejection Handle Pulled

If it were my aircraft, at every annual I would require the rtv to be removed, the hinge inspected, repaired as required, and then reapplied.

Not slapped on, and left there till the part failed.

Not slapped on, and left there till the part failed.