If you know, or had to guess, do the above closures and depopulations affect a particular consumer market, i.e., fast food/processed meats/convenience type foods vs raw meat markets like butcher shops, etc?Estimated Daily Livestock Slaughter

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Impending, possible meat shortages

- Thread starter flhrci

- Start date

Matthew

Touchdown! Greaser!

The Tyson plant in Holcomb, KS takes cattle from KS, OK, and TX. 6000 head a day. They had a fire last August that shut them down. It wasn't until about Jan that they got back to full production. They are still fully operational (about an hour west of National in Dodge).

Beef Plant Closures:

...

National in Dodge City, KS: On April 8, National Beef announced its first positive coronavirus case. The facility closed Thursday, April 16th through Tuesday, April 21st. The plant can process around 5,200 head per day.

...

PaulS

Touchdown! Greaser!

I think the question is more whether production cuts are just because things are closing and eventually reopening after being disinfected (the meat packing) vs having to toss product like your commercial packaging vs are we all eating less, or wasting less?

Or combo probably. ???

At the local level here, there’s not a lot of stuff one can’t get, if you want it. Maybe not a particular brand, but stuff is available. Vagaries of the supply chains I guess.

The restaurants are all doing take out but nowhere near their normal volume levels, but folks are eating... something... I assume.

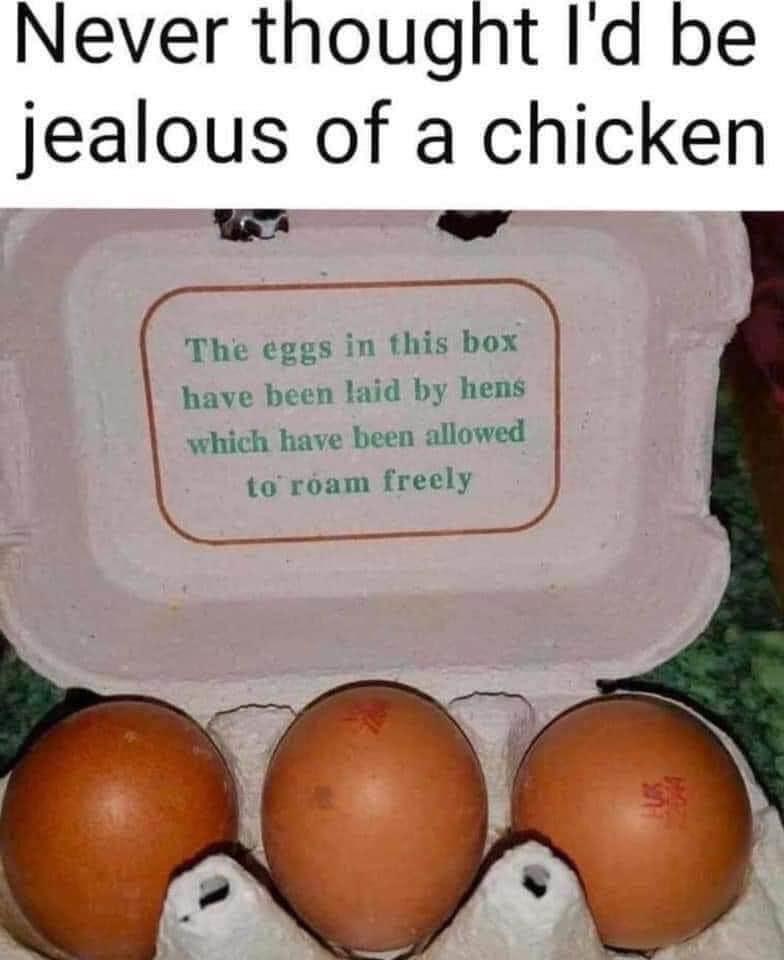

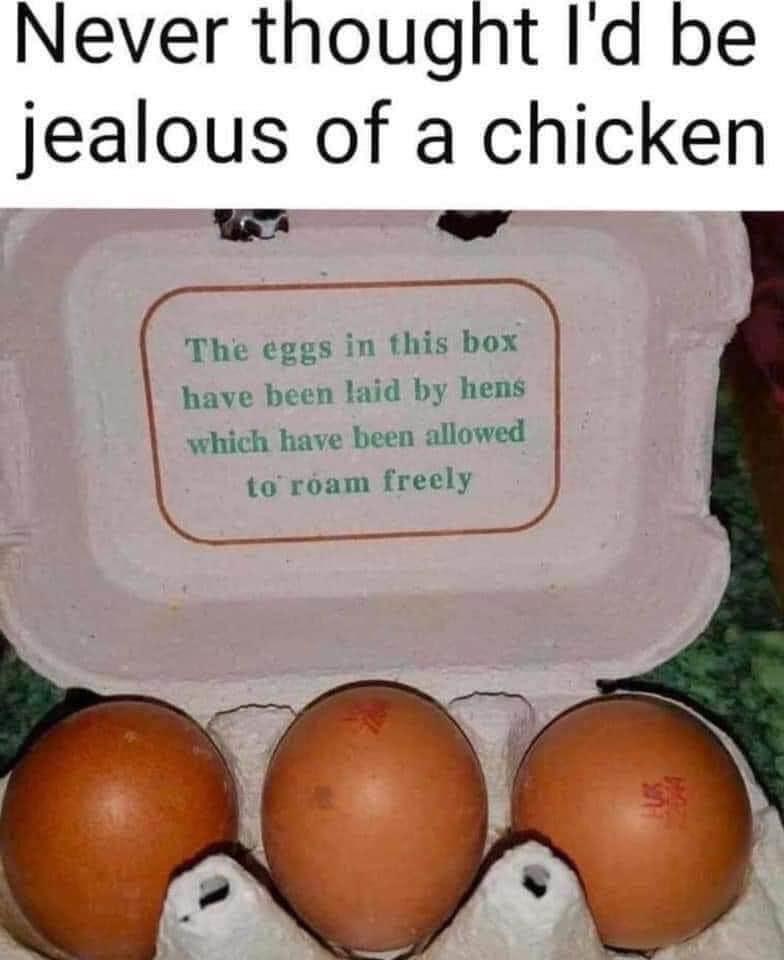

Seems like maybe we are personally eating less overall, but honestly my egg consumption has gone way up. Since I’m not dashing out the door in the morning, a couple of eggs and maybe another protein or a bit of cheese is often great... toss in the last nights leftover veg if there was some.

And often that does lead to a smaller lunch or just a healthy snack around lunchtime.

Like zero fast food and that’s not normal for me. Not a fast food junkie but usually are the stuff a couple times a week when busy commuting.

But round numbers your numbers look like we cut consumption by a quarter and I don’t think we have cut our calorie consumption by the same. Maybe.

Anyway. Eggs are tasty.

Will be buying more than usual for months in this house, I’m sure. A very convenient protein if I’m not sitting in traffic.

His answer as to why the shutdowns was Covid 19.

There is way too little information presented to make a determination as to what's going on here, thank you James_Dean for replying, and that's not a pick at you .

It seems to me not very smart to be shutting down food production plants because some employees are sick. My impression is that this is an industry where prevention of contamination is one of their leading strengths, once a problem like covid is identified I would think there are ways to limit employee exposure.

Talk about essential employees, I think our priorities might be a little mixed up. If I were running one of these operations the last thing I would want would be to open myself up to a bunch of politicians coming in and telling me how to fix things, which is very likely to happen if there is a run on super markets that these plants can't handle.

eman1200

Touchdown! Greaser!

- Joined

- Mar 10, 2013

- Messages

- 18,825

- Location

- Oakland, CA

- Display Name

Display name:

Bro do you even lift

…..I'm the president of #3 and #9 on the list below. I'm the current president of the Iowa Poultry Association, the Secretary of the United Egg Producers, and chairman of the UEP animal welfare committee.....

not to mention you have you're own song...……..

Dave Theisen

En-Route

eman1200

Touchdown! Greaser!

- Joined

- Mar 10, 2013

- Messages

- 18,825

- Location

- Oakland, CA

- Display Name

Display name:

Bro do you even lift

I’ve heard that @eman1200 is quite familiar with meat shortages.

I'm well aware of my meat shortage thank you very much.

Palmpilot

Touchdown! Greaser!

Thanks for letting us know what's going on!Uhh....Covid-19?

Beef Plant Closures:

Tyson in Wallula, WA (indefinitely closed): On April 23rd, Tyson announced it will indefinitely close its Wallula facility to test all employees. The plant employs around 1,400 people and can process about 2,300 head per day.

JBS in Green Bay, WI (indefinitely closed): As of April 22nd, at least 147 cases of coronavirus were linked to the Green Bay plant. On Sunday, April 26th, the company announced the indefinite closure of the facility. The facility can process about 900 head per day.

JBS in Greeley, CO: On April 12th, JBS announced it closed its Greeley facility for deep cleaning after dozens of employees tested positive for the coronavirus. The plant was slated to reopen Friday, April 24th. However, some industry sources say a Monday, April 27th opening is more likely. The facility can process about 5,400 head per day.

National in Tama, IA: The company shuttered operations on April 11th after numerous employees tested positive for the coronavirus. The facility reopened Monday, April 20th. The plant can process about 1,100 head per day.

CTI Foods in King of Prussia, PA (processing plant): Around April 10th, the hamburger grinding plant was closed due to coronavirus concerns. Wendell Young IV, president of the United Food and Commercial Workers Local 1776, said the plant has since been reopened.

National in Dodge City, KS: On April 8, National Beef announced its first positive coronavirus case. The facility closed Thursday, April 16th through Tuesday, April 21st. The plant can process around 5,200 head per day.

Cargill in Hazelton, PA (processing plant): On April 7th, it was announced that Cargill suspended operations at its Hazelton, Pa. facility to minimize the risk of spread between its employees. This location produces items such as ground beef and steaks and has since been reopened.

JBS in Souderton, PA: On March 31st, the JBS Souderton, Pa. plant “temporarily reduced production because several senior management team members have displayed flu-like symptoms”. The plant reopened Monday, April 20th. The facility can process about 2,500 head of cattle per day.

Beef Plants Under Watch:

Tyson in Dakota City, NE: On April 22nd, a labor union official said the plant had 23 workers who tested positive for the coronavirus, with more test results pending. Some industry sources have heard that the facility will be dark all this week, but details are elusive. The facility can process around 6,000 to 7,000 head per day.

JBS in Grand Island, NE: On April 21st, roughly 237 cases of coronavirus were reported at the Grand Island plant. The plant employs around 3,600 people and can process about 5,200 head per day.

WR Reserve in Lincoln, NE (processing plant): On April 14th, it was announced that at least ten workers tested positive for the coronavirus at the beef processing plant. The facility is located in Hastings, just south of Grand Island where positive cases were reported at a JBS plant.

Aurora Packing Company in Aurora, IL: Around April 13th, the beef plant was temporarily closed due to coronavirus concerns and has since reopened. The facility can process around 600 head per day.

Cargill in Fort Morgan, CO: On April 3rd, At least 102 workers at the Cargill facility tested positive for the coronavirus. The plant is reducing shifts in order to minimize the risk of spread. The location employs around 2,100 people and can process about 4,700 head per day.

Pork Plant Closures:

Indiana Packing Corp. in Delphi, IN: On Friday, April 24th, Indiana Packing Corp. announced that their Delphi facility will be closed for at least two weeks. Operations will be shuttered on Monday, April 27th. The plant is set to reopen around May 8th and can process around 17,300 hogs per day.

Smithfield in Monmouth, IL (indefinitely closed): On Friday, April 24th, Smithfield announced that it will suspend operations beginning this week until further notice. The plant can process around 12,600 head per day.

Tyson in Logansport, IN: On Wednesday, April 22nd, Tyson announced that it will temporarily close its Logansport location for at least two weeks after 146 employees tested positive for the coronavirus. The plant stopped all production on Saturday, April 25th. The facility can process around 15,400 hogs per day.

Prime Pork in Windom, MN: On Tuesday, April 21st, Prime Pork announced it will temporarily close its Windom plant for deep cleaning. Prime Pork expected to resume operations on Friday, April 24th, but production of some pork products will be suspended until the week of May 4th. The facility can process around 5,200 hogs per day.

JBS in Worthington, MN (indefinitely closed): On Monday, April 20th, JBS announced the indefinite closure of its Worthington plant following a coronavirus outbreak. The facility can process around 20,000 hogs per day.

Hormel Foods Corp. in Rochelle, IL, and Alma, KS (processing plants): On Monday, April 20th, two manufacturing plants under Hormell Foods Corp. closed due to a coronavirus outbreak. The Rochelle location produces items including bacon and lunch meat. The Alma location manufactures meals under the Saucy Blues foodservice brand. Both facilities plan to reopen on May 4th.

Tyson in Waterloo, IA (indefinitely closed): On Thursday, April 16th, an outbreak was reported at the Tyson plant in Waterloo. On Tuesday, April 22nd, the company announced plans to indefinitely suspend operations. The facility employs around 2,700 people and can process about 19,000 hogs per day.

Burgers' Smokehouse in California, MO (processing plant): On Thursday, April 16th, the company closed their facility after three employees tested positive for the coronavirus. The company is the largest producer of country ham in the United States. The facility plans to reopen on Thursday, April 30th.

Smithfield in Martin City, MO (processing plant): The Missouri processing plant indefinitely closed on Wednesday, April 15th. The plant employs around 400 people and produces spiral and smoked hams. The facility receives supplies from the indefinitely closed Sioux Falls, Smithfield plant.

Smithfield in Cudahy, WIS (processing plant): The Wisconsin processing plant closed on Wednesday, April 15th due to coronavirus concerns. The facility produces bacon and sausage and plans to reopen on April 29th.

Smithfield in Sioux Falls, SD (indefinitely closed): On Sunday, April 12th, Smithfield closed its Sioux Falls plant indefinitely after hundreds of employees tested positive for the coronavirus. The plant can process about 19,500 hogs per day, which represents 4% to 5% of U.S. pork production.

Fresh Mark in Salem, OH (processing plant): On Saturday, April 11th, the processing plant temporarily closed for deep cleaning. The facility produces items such as bacon, ham, and deli meats. The processing plant reopened Monday, April 20th.

Tyson in Columbus Junction, IA: On Monday, April 6th, Tyson announced that its Columbus Junction plant was suspending operations after more than two dozen employees tested positive for the coronavirus. The facility can process about 10,100 hogs per day. Tyson resumed limited operations on Monday, April 21st. Industry sources report that the plant is currently operating at 50% capacity, roughly 5,050 head per day.

Pork Plants Under Watch:

Smithfield in Crete, NC: On Sunday, April 26th, it was announced that nearly 50 employees tested positive for the coronavirus. The facility can process around 11,000 hogs per day.

JBS in Marshalltown, IA: On Tuesday, April 21st, it was announced that 34 employees at the Marshalltown plant tested positive for the coronavirus. The facility can process around 21,000 hogs per day and remains open.

Tyson in Perry, IA: Tyson halted operations at its Perry location on Monday, April 20th for deep cleaning. The facility has since reopened and can process around 7,600 hogs per day.

Smithfield in Tar Heel, NC: An employee at the Smithfield processing plant in Tar Heel, North Carolina, tested positive for the coronavirus on Saturday, April 18th. This is the largest facility in the United States with a capacity of around 33,500 hogs per day.

Prestage Foods in Eagle Grove, IA: On Saturday, April 18th and Sunday, April 19th, it was confirmed that sixteen employees tested positive for the coronavirus at the plant. The facility can process around 10,000 hogs per day.

Seaboard in Guymon, OK: Seaboard confirmed its first positive coronavirus case at its Guymon location on Monday, April 13th. The plant is still currently operating and can process about 19,600 hogs per day.

Tyson in Madison, NE: Health officials are investigating a possible coronavirus outbreak at the plant. The facility employs around 1,200 people and can process about 8,000 hogs per day.

Poultry Plant Closures:

Homel Foods in Willmar, MN (indefinitely closed): On April 24th, Hormel Foods' Jennie-O Turkey Store announced that it was temporarily closing two facilities in Minnesota after 14 employees tested positive for the coronavirus.

West Liberty Foods in West Liberty, IA: On April 10th, the processing plant closed for three days after three employees tested positive for the coronavirus. The plant processes turkey, beef, pork, and chicken for foodservice and retail. The facility reopened on April 14th.

Empire Kosher Poultry in Mifflintown, PA: On April 3rd, the chicken processing plant closed for two weeks after two employees tested positive for the coronavirus. The facility reopened Monday, April 20th.

Sanderson Farms in Moultrie, Georgia: On April 2nd, it was announced that Sanderson Farms was reducing chicken processing to 1 million birds a week from 1.3 million over the next four weeks at its Moultrie facility.

GrummanBear

Ejection Handle Pulled

- Joined

- Jan 28, 2020

- Messages

- 225

- Display Name

Display name:

X

Wow, looks like they might just force us all to go vegetarian

smv

Pattern Altitude

- Joined

- Dec 30, 2019

- Messages

- 1,661

- Display Name

Display name:

smv

It's another tool in the toolbox for surviving hard times. Not everyone has the options that you do.

Even central park has squirrels. You just gotta be stealthy and know how to find them after dark.

denverpilot

Tied Down

A chuckle ...

gkainz

Final Approach

well talk about bad luck and horrible timing ... I noted up there (^) somewhere that we had 2 steers in processing from a friend ... just found out last night the processor had a fire and the carcasses were ruined. Next beef available from her is now into June. Looks like we'll be elbowing our way up to the Costco meat counter today.

Chip Sylverne

Final Approach

- Joined

- Jun 17, 2006

- Messages

- 5,888

- Display Name

Display name:

Quit with the negative waves, man.

JOhnH

Touchdown! Greaser!

I saw an article about someone predicting a meat shortage in grocery stores by Friday. The local grocery store has early shopping for seniors and my wife likes me to go at that time because the store has been sanitized overnight. I went this morning at 7:10. Senior shopping starts at 7:00. There were already a bunch of shopping carts overflowing with meat and when I got to the meat counter it was pretty picked over. But I stocked up on a 6# pork butt (on sale), a package of chicken breasts and a couple of filet mignons for Friday and package of ground turkey that my wife uses to make cat food. I wasn't hoarding but with the lockdown orders, I try to only go to the store every other week or so. There wasn't much else there so I am glad I got there early.

I'm sure that what @James_Dean said about a shortage is true, but the alarming articles in the paper causing a hoarding rush on meat will ensure that it turns out to be like the toilet paper shortage, and sooner than necessary.

I'm sure that what @James_Dean said about a shortage is true, but the alarming articles in the paper causing a hoarding rush on meat will ensure that it turns out to be like the toilet paper shortage, and sooner than necessary.

Kenny Phillips

Final Approach

- Joined

- Jul 29, 2018

- Messages

- 5,493

- Display Name

Display name:

Kenny Phillips

You can bet that they shut down to limit their liability. Unless congress OKs blanket immunity [hah!] to businesses that may unwittingly spread COVID-19, some people will take the safe option.His answer as to why the shutdowns was Covid 19.

There is way too little information presented to make a determination as to what's going on here, thank you James_Dean for replying, and that's not a pick at you .

It seems to me not very smart to be shutting down food production plants because some employees are sick. My impression is that this is an industry where prevention of contamination is one of their leading strengths, once a problem like covid is identified I would think there are ways to limit employee exposure.

Talk about essential employees, I think our priorities might be a little mixed up. If I were running one of these operations the last thing I would want would be to open myself up to a bunch of politicians coming in and telling me how to fix things, which is very likely to happen if there is a run on super markets that these plants can't handle.

Bill

Touchdown! Greaser!

- Joined

- Mar 2, 2005

- Messages

- 15,101

- Location

- Southeast Tennessee

- Display Name

Display name:

This page intentionally left blank

How was it government or management, at the first hint of this pandemic, didn't think to start taking workers temperatures on the way in the door at the start of every shift. How is it food security wasn't even a consideration.

We are essential and still working, there has been a nurse at the facillity taking temperatures at the beginning of each shift. That was put into place March 1.

I'm sure that what @James_Dean said about a shortage is true, but the alarming articles in the paper causing a hoarding rush on meat will ensure that it turns out to be like the toilet paper shortage, and sooner than necessary.

Manufactured shortages, just like the economic downturn of 2008/9. All our controllers (I mean media) has to do is tell it long and loud enough, and people will buy in to whatever calamity they're selling. Sheeple indeed.

Chip Sylverne

Final Approach

- Joined

- Jun 17, 2006

- Messages

- 5,888

- Display Name

Display name:

Quit with the negative waves, man.

You can bet that they shut down to limit their liability. Unless congress OKs blanket immunity [hah!] to businesses that may unwittingly spread COVID-19, some people will take the safe option.

If management's primary concern was to meet production quotas without regard to employee or public health, they ought to be accountable. I don't see how they could have been unaware of the risk after March 1. It's the rare enterprise that will take proactive measures before an authority makes it a requirement. The pooch was screwed in this whole episode, top to bottom.

Chip Sylverne

Final Approach

- Joined

- Jun 17, 2006

- Messages

- 5,888

- Display Name

Display name:

Quit with the negative waves, man.

We are essential and still working, there has been a nurse at the facillity taking temperatures at the beginning of each shift. That was put into place March 1.

Are you employed in the food supply chain? What do you do?

Bill

Touchdown! Greaser!

- Joined

- Mar 2, 2005

- Messages

- 15,101

- Location

- Southeast Tennessee

- Display Name

Display name:

This page intentionally left blank

Are you employed in the food supply chain? What do you do?

No, I do product engineering and management. We make hermetic electronic packaging for the medical, oil field, military, and space industries. Many DPAS rated orders, so we continue on.

GrummanBear

Ejection Handle Pulled

- Joined

- Jan 28, 2020

- Messages

- 225

- Display Name

Display name:

X

If management's primary concern was to meet production quotas without regard to employee or public health, they ought to be accountable. I don't see how they could have been unaware of the risk after March 1. It's the rare enterprise that will take proactive measures before an authority makes it a requirement. The pooch was screwed in this whole episode, top to bottom.

Do we really have to sue or jail or blame everything on people? I think the lockdowns in south Texas are absolute nonsense, and my wife is increasingly upset at the death and health outcomes she is seeing at her trauma center in the elderly population (non-covid, resultant from lockdown effects) and gruesome domestic violence patients that keep coming in...but the liberal mayor and judge here are trying to serve and protect, even if it may be backfiring. Sometimes s*** happens.

Chip Sylverne

Final Approach

- Joined

- Jun 17, 2006

- Messages

- 5,888

- Display Name

Display name:

Quit with the negative waves, man.

No, I do product engineering and management. We make hermetic electronic packaging for the medical, oil field, military, and space industries. Many DPAS rated orders, so we continue on.

So you're trusted and valuable, highly skilled employees. It's no wonder management wants to keep you and your cohort healthy, you're hard to replace.

Not so the typical slaughterhouse labor.

Chip Sylverne

Final Approach

- Joined

- Jun 17, 2006

- Messages

- 5,888

- Display Name

Display name:

Quit with the negative waves, man.

Do we really have to sue or jail or blame everything on people? I think the lockdowns in south Texas are absolute nonsense, and my wife is increasingly upset at the death and health outcomes she is seeing at her trauma center in the elderly population (non-covid, resultant from lockdown effects) and gruesome domestic violence patients that keep coming in...but the liberal mayor and judge here are trying to serve and protect, even if it may be backfiring. Sometimes s*** happens.

The question is was there reckless disregard for the consequences of a foreseeable event? I'm not so sure there is here, at least on the part of the meat packers. What I am convinced of was that no one had the foresight to think "Geez, this might have an effect on the food supply chain" and put in place mitigating procedures.

Last edited:

JOhnH

Touchdown! Greaser!

No, we don't HAVE to.Do we really have to sue or jail or blame everything on people?

And we SHOULDN'T.

But we do. And that is why so many producers are shutting down. It probably feels a little better to be put out of business over something you can't control than something you can.

deonb

Pattern Altitude

- Joined

- Aug 17, 2015

- Messages

- 2,266

- Display Name

Display name:

deonb

I'm sure that what @James_Dean said about a shortage is true, but the alarming articles in the paper causing a hoarding rush on meat will ensure that it turns out to be like the toilet paper shortage, and sooner than necessary.

I think the difference though is that meat has always had variable pricing that changes almost daily, where toilet paper has fixed pricing. When meat gets scare prices will double, triple or more, until supply and demand is in balance.

The higher prices should discourage a hoarding-induced feedback loop like we had for toilet paper. Also, it's not something that people have unlimited storage space for.

Bill

Touchdown! Greaser!

- Joined

- Mar 2, 2005

- Messages

- 15,101

- Location

- Southeast Tennessee

- Display Name

Display name:

This page intentionally left blank

So you're trusted and valuable, highly skilled employees. It's no wonder management wants to keep you and your cohort healthy, you're hard to replace.

Not so the typical slaughterhouse labor.

Point, but still, what's the cost of a nurse or three vs. a full plant shutdown? Very shortsighted.

Matthew

Touchdown! Greaser!

I'll be headed to Sam's in the near future for meat - my cholesterol is getting dangerously low, so it's time to fire up the smoker again. I hope there is something left for the regular folk like me.

JOhnH

Touchdown! Greaser!

I believe you are about a 5.5 hour flight for me, not counting a potty break.I'll be headed to Sam's in the near future for meat - my cholesterol is getting dangerously low, so it's time to fire up the smoker again. I hope there is something left for the regular folk like me.

When Is the coookout?

RJM62

Touchdown! Greaser!

- Joined

- Jun 15, 2007

- Messages

- 13,157

- Location

- Upstate New York

- Display Name

Display name:

Geek on the Hill

I'll be headed to Sam's in the near future for meat - my cholesterol is getting dangerously low, so it's time to fire up the smoker again. I hope there is something left for the regular folk like me.

They had plenty when I was there Sunday. I also suspect that they have a pretty redundant supply chain because of Walmart's size (where they have a huge advantage over Costco and BJ's).

Coupled with the lack of demand from the foodservice sector, I think the wholesale clubs, especially Sam's Club, are probably the best bets for meat right now. The exception would be in rural areas where farmers are selling directly to the public, legally or otherwise.

Rich

Matthew

Touchdown! Greaser!

Just give me a couple day's notice!I believe you are about a 5.5 hour flight for me, not counting a potty break.

When Is the coookout?

If you can't make it to my place, head over to Melbourne. My brother doesn't need much of a reason to start up his smoker.

We are essential and still working, there has been a nurse at the facillity taking temperatures at the beginning of each shift. That was put into place March 1.

Manufactured shortages, just like the economic downturn of 2008/9. All our controllers (I mean media) has to do is tell it long and loud enough, and people will buy in to whatever calamity they're selling. Sheeple indeed.

Follow the money.

When you get a bunch of numbnut experts preaching to the other numbnuts, "THERE'S A SHORTAGE COMING!!!!!!" The numbnuts make the shortage come true. (Hum, where have we seen that?)

There is NO meat shortage. They've been trying to create one for several few weeks now. So far, maybe because some of the numbnuts have figured out how they got duped by the fake TP shortage, maybe they're a little slower to react this time. Yes, as they continue to force this b.s. on us, we'll eventually have one.

There are however, major failures in the supply chain. Massive monopolies are like huge ships. They can't be turned on a dime. They would rather temporarily step over dollar bills, than to pick up nickels, because in the end, they'll suck their temporary losses back out of the consumer. They can do this because they're the only game in town. Our fault for allowing this situation to continue. Don't be manipulated. Think for yourself. Sure, if you speak out, you risk exposing yourself to the scorn of the lo quotient folks and the high power crooks, but in the end, it's a step in the right direction for a sorely needed change.

Follow the money.

JOhnH

Touchdown! Greaser!

At least you got that part right.There are however, major failures in the supply chain. Massive monopolies are like huge ships. They can't be turned on a dime.

So what do YOU suggest? Should we all go buy a calf and some chickens? And a few acres for them to graze?Our fault for allowing this situation to continue. Don't be manipulated. Think for yourself.

That would be fine if we could arrange to reduce the population of the US by about a hundred million or so and the population of the world by a couple of billion people. And living on a commune like the hippies tried when I was in high school. We NEED high volume, efficient food producers. Personally, I prefer getting my ribs from Sams or Publix than by killing a cow and slicing off parts for my family to eat.

Last edited:

MuseChaser

Pattern Altitude

- Joined

- Feb 23, 2019

- Messages

- 2,039

- Display Name

Display name:

MuseChaser

Just gonna leave this here. I made this a few months ago. With a younger squirrel, it would have been really good. The two I used would have been better in a burgoo or bigos or curry, but it was still good and an interesting departure from most common ways to cook squirrel...

GrummanBear

Ejection Handle Pulled

- Joined

- Jan 28, 2020

- Messages

- 225

- Display Name

Display name:

X

Hunting NYC...Just gonna leave this here. I made this a few months ago. With a younger squirrel, it would have been really good. The two I used would have been better in a burgoo or bigos or curry, but it was still good and an interesting departure from most common ways to cook squirrel...

Hunting Texas...

Good job security!No, I do product engineering and management. We make hermetic electronic packaging for the medical, oil field, military, and space industries. Many DPAS rated orders, so we continue on.

I'll be headed to Sam's in the near future for meat - my cholesterol is getting dangerously low, so it's time to fire up the smoker again. I hope there is something left for the regular folk like me.

When are we going to do a POA Fly-in BBQ and have you officiate it?Just give me a couple day's notice!

James_Dean

Pattern Altitude

Not so the typical slaughterhouse labor.

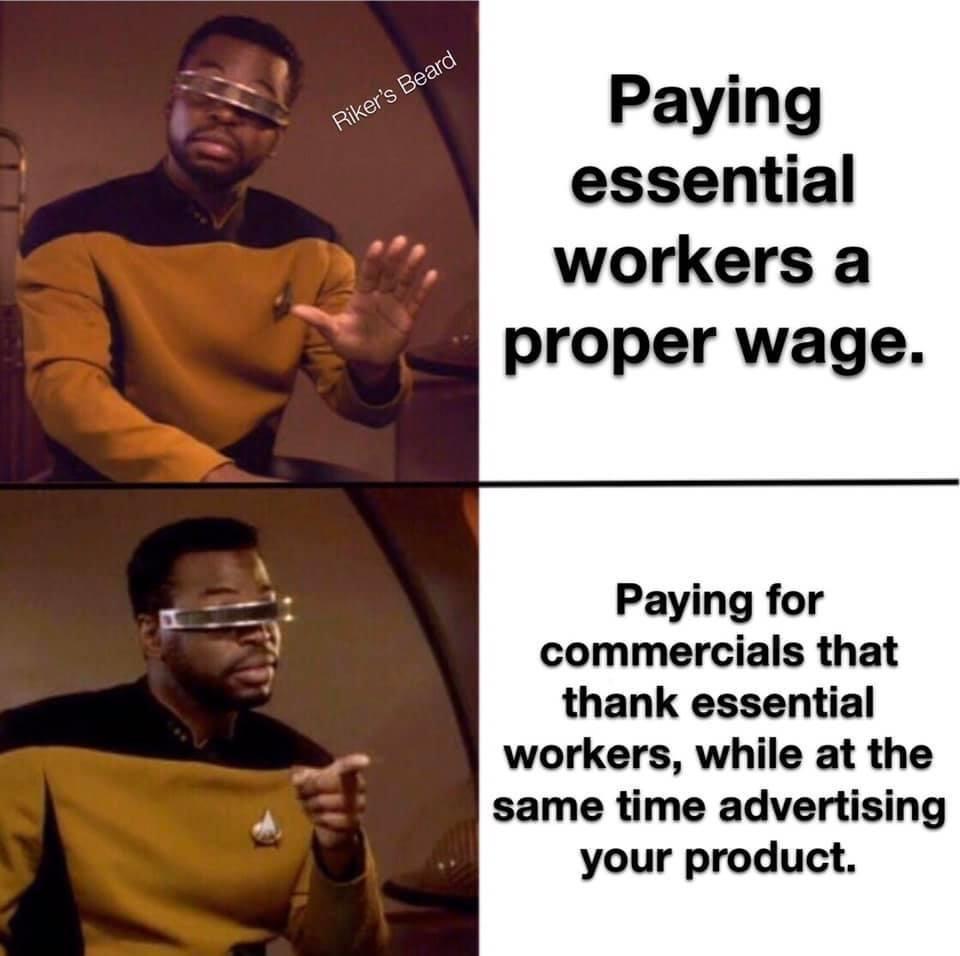

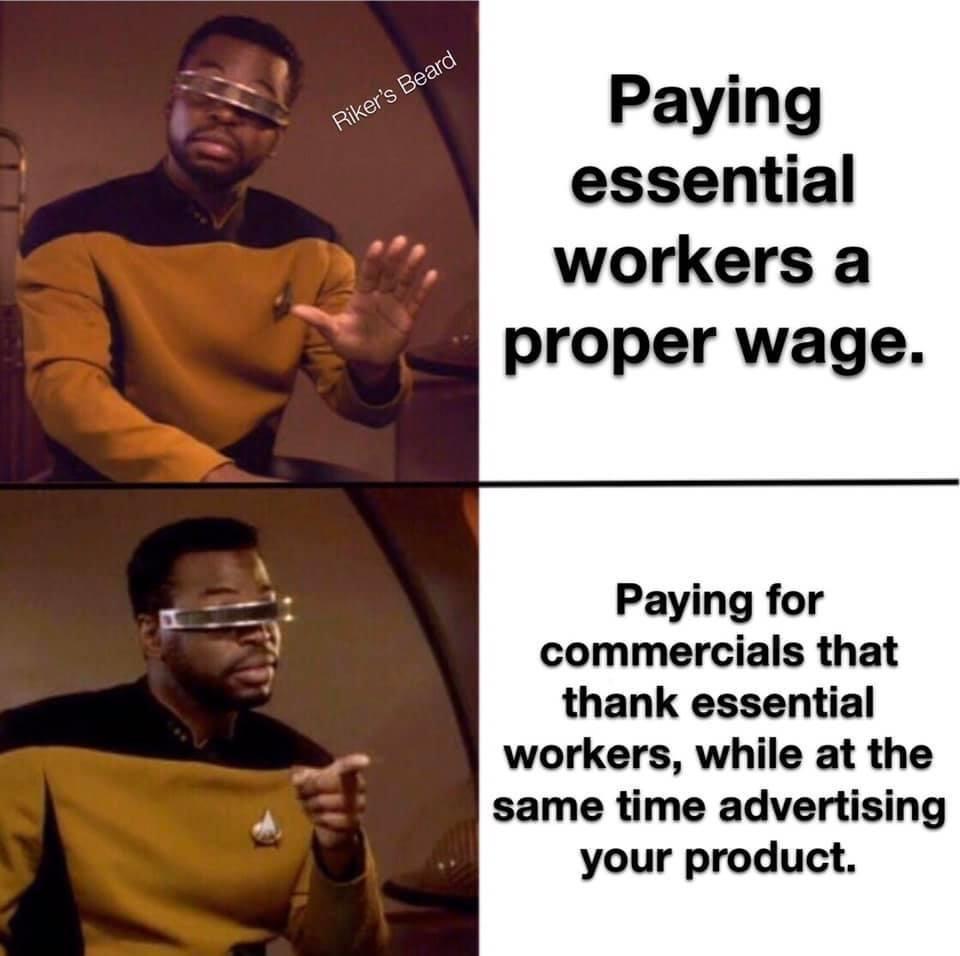

We have 1500 team members and 60 something locations. The policy changes and procedure development have been constant. Forgive me if this isn't all 100% stated perfectly -

We implemented a $2/hr bonus for all people at facilities in states with shelter in place policies.

Keeping people away if they are at all ill, while removing any fear of economic consequences has bee challenging. We suspended our attendance policy. If you want to stay home voluntarily you can use your PTO. After PTO runs out you either need to produce a doctors not(which you can get through our tele-doc program) or just continue to stay home. If you elect to stay home you would not be terminated, but would be eligible for unemployment under CARES. If you get the doc note for cause we provide pay for two weeks and they you are eligible for our short term disability program. If you get COVID or are quarantined, you first use your PTO and then we continue straight time pay until you can return to work.

We implemented a pre-work wellness check and questionnaire with a temperature check.

We slowed lines down where appropriate and implemented distancing procedures. Those included additional break spaces, physical barriers between work stations, adding additional automation, and crew rotation schedules. Masks are required.

We use backpack electrostatic sanitizer applicators in all plant work spaces on regular intervals.

About 724 other things that I'm leaving out for brevity. All of these things need to have procedures written, checked by legal, cost analysis done, supplies ordered, and approval by regulators. It all takes time, and money. The cost for all the above is easily in the millions.

So far we have only had one positive case. However, due to the nature of the timing it caused us to put 36 other people in quarantine from work for 14 days. 36 people who were gathering eggs after we had a devastating fire last week. We now have testing available and are trying to figure out how to best deploy it. We have both PCR and Elisa which will allow us to group our team members into one of four catagories -

1. Not shedding, and never been exposed. Can be at work, but high risk.

2. Currently shedding, but no detectable antibodies. Early stage infection. Best to quarantine for 14 days.

3. Currently shedding, and detected antibodies. Later state infection. Might be able to return to work with mask per CDC guidelines

4. Not currently shedding, and detected antibodies. Was infected and now healthy. Clear to be at work.

All while remembering that the birds have to be fed and the eggs gathered every day. No exceptions.

This is all easier said than done. It's not rocket surgery, but it ain't easy either.

James_Dean

Pattern Altitude

I think the difference though is that meat has always had variable pricing that changes almost daily, where toilet paper has fixed pricing. When meat gets scare prices will double, triple or more, until supply and demand is in balance.

The higher prices should discourage a hoarding-induced feedback loop like we had for toilet paper. Also, it's not something that people have unlimited storage space for.

Until you get sued for price gouging.

https://www.houstonchronicle.com/ne...ing-eggs-Texas-AG-sues-Cal-Maine-15222218.php

https://www.businessinsider.com/lawsuit-trader-joes-costco-amazon-hiked-up-egg-prices-report-2020-4

PaulS

Touchdown! Greaser!

We have 1500 team members and 60 something locations. The policy changes and procedure development have been constant. Forgive me if this isn't all 100% stated perfectly -

We implemented a $2/hr bonus for all people at facilities in states with shelter in place policies.

Keeping people away if they are at all ill, while removing any fear of economic consequences has bee challenging. We suspended our attendance policy. If you want to stay home voluntarily you can use your PTO. After PTO runs out you either need to produce a doctors not(which you can get through our tele-doc program) or just continue to stay home. If you elect to stay home you would not be terminated, but would be eligible for unemployment under CARES. If you get the doc note for cause we provide pay for two weeks and they you are eligible for our short term disability program. If you get COVID or are quarantined, you first use your PTO and then we continue straight time pay until you can return to work.

We implemented a pre-work wellness check and questionnaire with a temperature check.

We slowed lines down where appropriate and implemented distancing procedures. Those included additional break spaces, physical barriers between work stations, adding additional automation, and crew rotation schedules. Masks are required.

We use backpack electrostatic sanitizer applicators in all plant work spaces on regular intervals.

About 724 other things that I'm leaving out for brevity. All of these things need to have procedures written, checked by legal, cost analysis done, supplies ordered, and approval by regulators. It all takes time, and money. The cost for all the above is easily in the millions.

So far we have only had one positive case. However, due to the nature of the timing it caused us to put 36 other people in quarantine from work for 14 days. 36 people who were gathering eggs after we had a devastating fire last week. We now have testing available and are trying to figure out how to best deploy it. We have both PCR and Elisa which will allow us to group our team members into one of four catagories -

1. Not shedding, and never been exposed. Can be at work, but high risk.

2. Currently shedding, but no detectable antibodies. Early stage infection. Best to quarantine for 14 days.

3. Currently shedding, and detected antibodies. Later state infection. Might be able to return to work with mask per CDC guidelines

4. Not currently shedding, and detected antibodies. Was infected and now healthy. Clear to be at work.

All while remembering that the birds have to be fed and the eggs gathered every day. No exceptions.

This is all easier said than done. It's not rocket surgery, but it ain't easy either.

Can't argue with any of that James, thanks for taking the time to respond. Generally if you treat employees well and fairly, they want to work and do a good job, looks like you know that. I hope you are able to overcome this quickly.

denverpilot

Tied Down

James is the top one. LOL.

James_Dean

Pattern Altitude

Can't argue with any of that James, thanks for taking the time to respond. Generally if you treat employees well and fairly, they want to work and do a good job, looks like you know that. I hope you are able to overcome this quickly.

Thanks, and so do I.

Per @Art Rose, I'll just get together with all the other big shots, adjust our monocles, twirl our mustaches, and sip our brandy in our gilded cages while we cackle and plot. We'll make $$$$$$$$$$$$$$$$. Muhaahaaahaaa.

Or, we'll just do what farmers always do. ***** for a few minutes over some coffee and get back to work.

Looks like the food supply chain is now considered critical infrastructure and will have the Defense Production Act applied to it.

https://www.newsmax.com/finance/streettalk/trump-tyson-liability-order/2020/04/28/id/965041/

https://www.newsmax.com/finance/streettalk/trump-tyson-liability-order/2020/04/28/id/965041/