Thats what I hate about sitting near the front of the Otter when I skydive. Im sitting RIGHT by that spinning prop thinking about a blade coming off...

Riding up front in an Aerostar is just as sobering....

Thats what I hate about sitting near the front of the Otter when I skydive. Im sitting RIGHT by that spinning prop thinking about a blade coming off...

ethinks I got really, really lucky to walk away from that one...

I have a BRS for this possibility...

...but the front bridles attach to the engine mount.

This is my great-grandfather's lost-prop story. The article says "part of the engine" fell off after the propeller broke but as the story was told to me, the prop split in the middle and fell off its mount, I don't think anything else fell off.

So the engine gets down safely?

Nice story, what was the date?

If you are flying and you lose a chunk of it. Not the whole thing but lets say half a blade...

I'd be very surprised to see half a blade let go. Stress is highest at the hub, and that's where the blade necks (no, no that kind of necking -- NTTAWWT if you REALLY like your plane, but I digress) and further concentrates stress. Most of the cases I've seen reported involve CS props defenestrating a whole blade from its attachment point. You'd nave to break a lot of material to lose just a part.

There were 3 or 4 fatal T-18 crashes back when the design first came out because people were cutting down aluminum props that ended up resonating at cruise rpm and failing from fatigue. Type certificated aircraft are more likely to get more of an analysis done to make sure this isn't happening (and sometimes you get rpm bands that are not allowed for normal operation).I wonder if these events are more common with homebuilts, racers, and other experimentals.

I wouldn't say cracks propagate any easier over thin sections than thick....it depends on the stress concentration not the thickness.Yeah but it's a thicker cross section at the hub too. Cracks propagate easier over a thin cross section.

Type certificated aircraft are more likely to get more of an analysis done to make sure this isn't happening (and sometimes you get rpm bands that are not allowed for normal operation).

There were 3 or 4 fatal T-18 crashes back when the design first came out because people were cutting down aluminum props that ended up resonating at cruise rpm and failing from fatigue. Type certificated aircraft are more likely to get more of an analysis done to make sure this isn't happening (and sometimes you get rpm bands that are not allowed for normal operation).

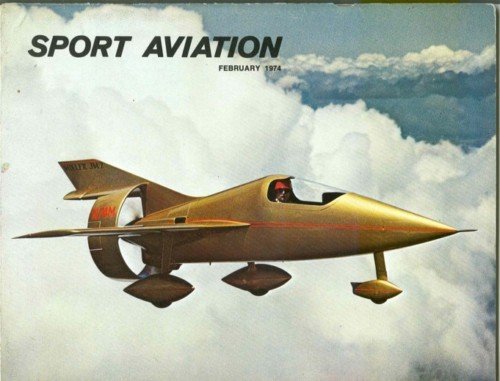

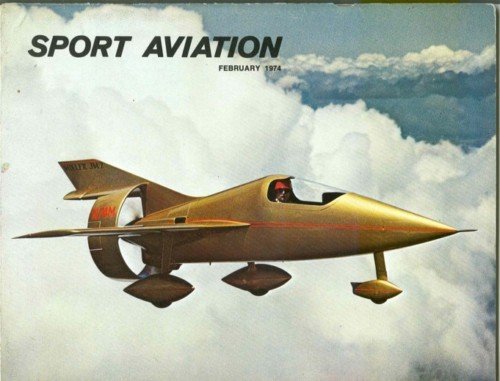

That's a Miller Special - a pusher F1 design. I think 3 were built, the most famous being "Pushy Galore"...

https://www.google.com/search?q=pus...hUKEwi0srzz27TKAhUBZyYKHZ_TDOkQ_AUIBigB&dpr=1

harmonics....music to an engineer's ears.And this, children, is why you pay attention to the RPM and MP restrictions in the POH...

It was even cooler when the prop was ducted:

And the resultant instantaneous overspeed can cause the engine to come apart and make a mess.

Now that pic caught my eye; I took it! I was flying this C-310 when the prop came apart, Nov. 1991. Photo data tag says it came from Aopa.org; I wonder where they found it? I must have posted it somewhere long ago and forgot about it. No biggie.