455 Bravo Uniform

Final Approach

Being upset that I have not flown due to the lame excuse of cold wx, and

Being too cheap and lazy to do an oil-pan and/or cylinder head heating solution, and

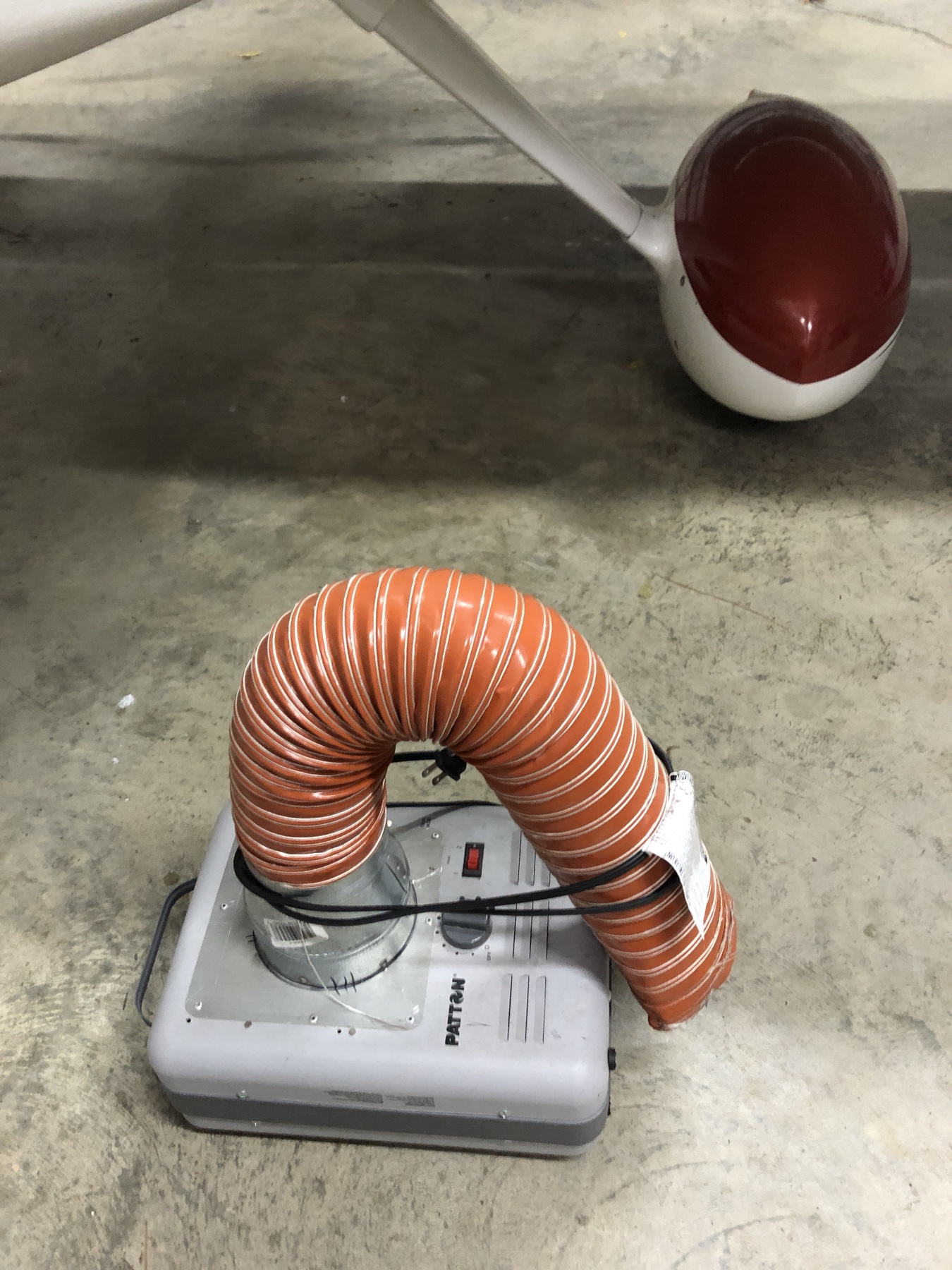

Having a few moments of boredom and some stuff laying around, I made this abomination:

I had the ceramic heater, some scrap sheet metal, and aluminum tape. I bought a $7 a/c vent fitting, $6 aluminum flexible 3” duct 8 ft long, and $2 for 3” clamps.

The duct hose will attach to the dragon nostrils with clamps, then I will fit the other end of the hose to each cowl flap.

I figured since heat rises, I’d take advantage of heating the bottom of the oil pan and allowing the rest of the heated air to rise to the cylinders.

I’m going to put a thermometer in front of the cowl to see if I can get any exit air temp increase (may not even reach there, we’ll see).

I may even burn up the heater if I get too little air movement thru it....

Being too cheap and lazy to do an oil-pan and/or cylinder head heating solution, and

Having a few moments of boredom and some stuff laying around, I made this abomination:

I had the ceramic heater, some scrap sheet metal, and aluminum tape. I bought a $7 a/c vent fitting, $6 aluminum flexible 3” duct 8 ft long, and $2 for 3” clamps.

The duct hose will attach to the dragon nostrils with clamps, then I will fit the other end of the hose to each cowl flap.

I figured since heat rises, I’d take advantage of heating the bottom of the oil pan and allowing the rest of the heated air to rise to the cylinders.

I’m going to put a thermometer in front of the cowl to see if I can get any exit air temp increase (may not even reach there, we’ll see).

I may even burn up the heater if I get too little air movement thru it....