yup.....I'd avocate warmer startups are less wear and more better for all the moving parts.

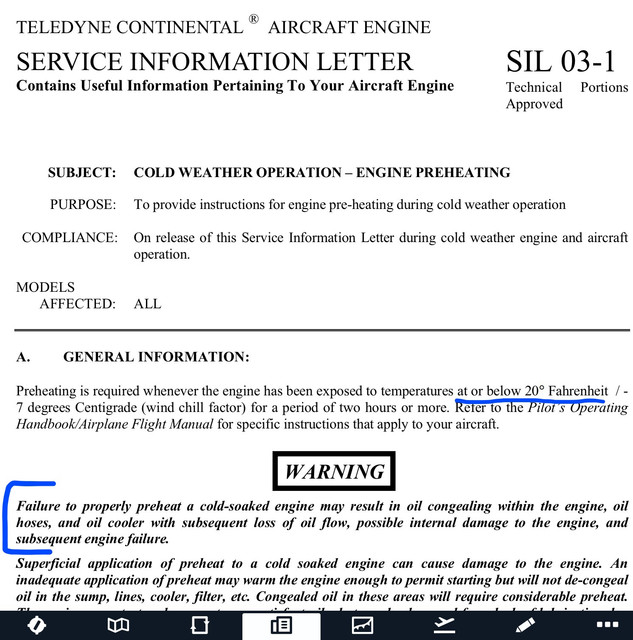

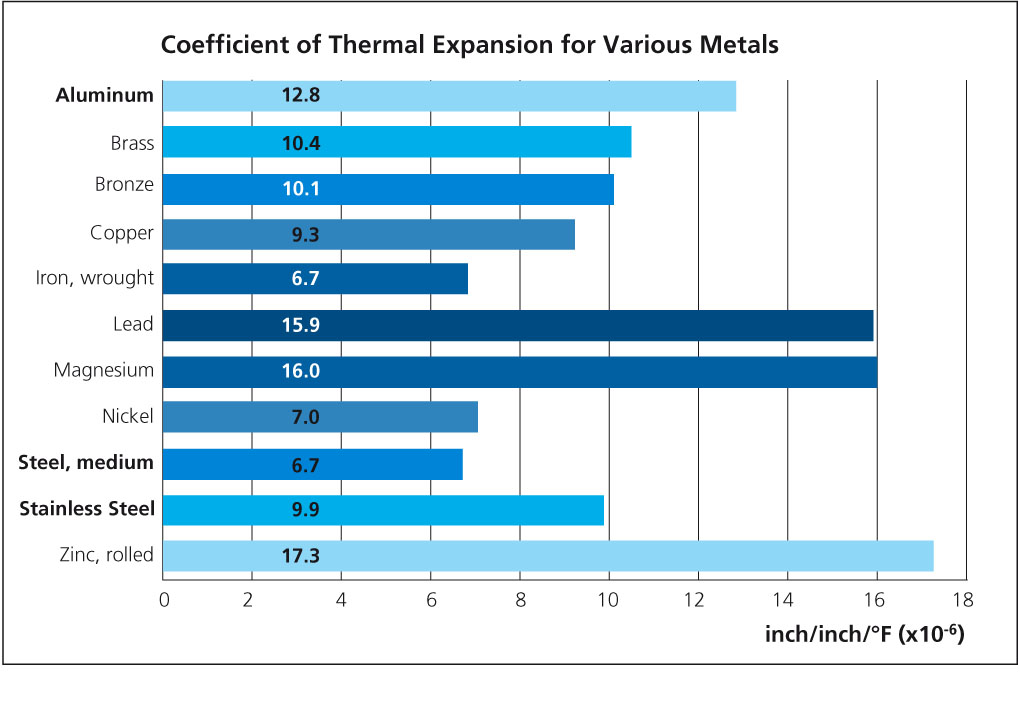

A good friend of mine was a Lycoming engineer and for grins did a stackup analysis of an old design and discovered a few things. Those "things" never made it to the marketing glossy documents. The first was the "possibility", a remote one but, none the less, possibility of spinning a main bearing due to a cold thermal interference. The parts have to be mixed and matched just right on a "new" engine....but mathematically he was able to have metal to metal contact on the front main journal bearing....enough for it to spin ....at temps around 32 F. An older engine, one with wear, wouldn't have this issue. Another discovery was the possibility of a thermal induced line-to-line or metal contact in the choke area of the cylinder with the piston & rings. All due to differences in thermal expansion or coefficient of thermal expansion between steel and aluminum parts.

The second observation is well known and the evidence can be observed when tearing down tired cylinders....