PaulMillner

Line Up and Wait

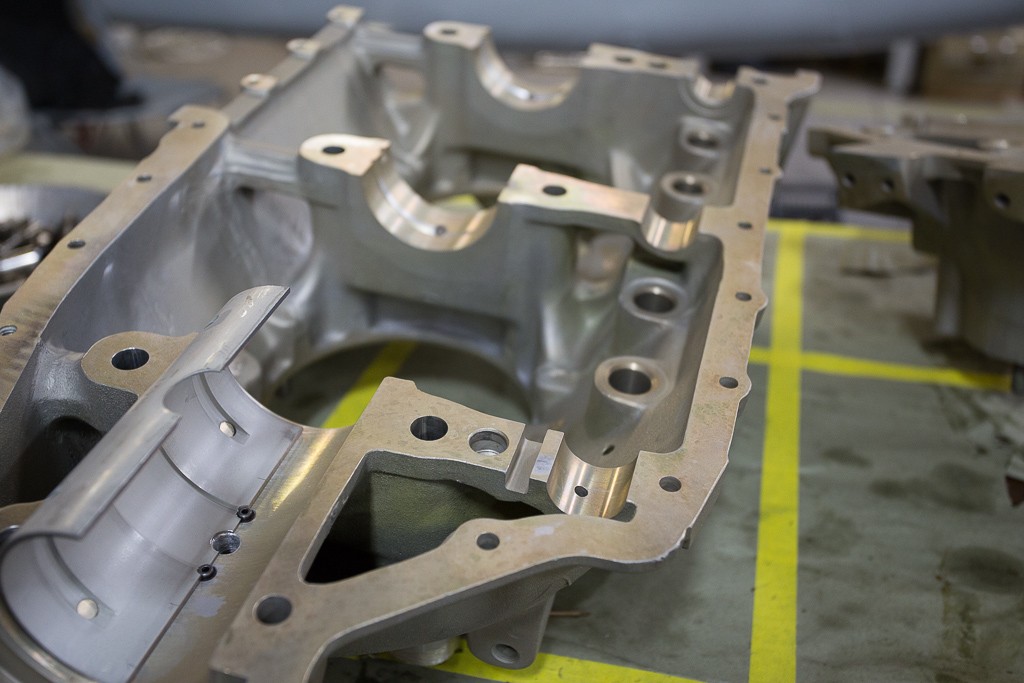

In the restart Cessnas, Cessna & Lycoming increased maximum oil pressure red line from 100 psig to 115 psig for the restart Cessnas... and made another virtual increase of 10 psig by relocating the sensing point from the back of the engine to the front of the engine, where the pressure is lower.

A friend believes he saw *somewhere* an STC that allows making this change on earlier engines... relocate the pressure tap, and remark the oil pressure red line to 115 from 100. Folks are interested in this to promote better valve train lubrication. See the Bill & Bill discussions in Aviation Consumer and other places in the late 90's... link:

http://secure4host.net/upload/files/...ion2013-08.pdf

Is anyone aware of such an STC? The drawing linked below is supposedly associated with this STC... is Lycoming offering this guidance, or some third party?

Thanks in advance for what you know!

Paul

http://www.secure4host.net/upload/fi...g_oil_line.jpg

A friend believes he saw *somewhere* an STC that allows making this change on earlier engines... relocate the pressure tap, and remark the oil pressure red line to 115 from 100. Folks are interested in this to promote better valve train lubrication. See the Bill & Bill discussions in Aviation Consumer and other places in the late 90's... link:

http://secure4host.net/upload/files/...ion2013-08.pdf

Is anyone aware of such an STC? The drawing linked below is supposedly associated with this STC... is Lycoming offering this guidance, or some third party?

Thanks in advance for what you know!

Paul

http://www.secure4host.net/upload/fi...g_oil_line.jpg