Half Fast

Touchdown! Greaser!

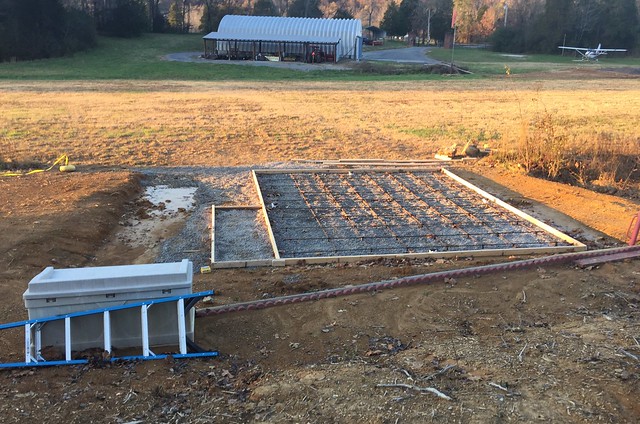

Eddie, are you going to sink tie-down rings into the concrete? I didn't notice anything in the photo, but it was taken from a distance.

When I order concrete I plan on a little extra and have a plan for pouring the extra on my site. maybe a ramp up to the slab...

When I order concrete I plan on a little extra and have a plan for pouring the extra on my site. maybe a ramp up to the slab...

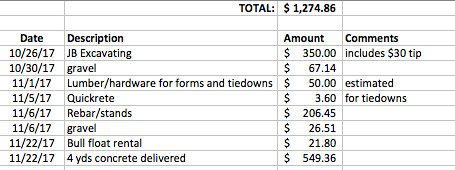

Yeah, thats exactly what I do. Much better than possibly running short on the main slab.Worked on finalizing things today, and took your advice:

If there’s excess, I’ll have it added to that little extension. I left one side movable, so I can expand it to take whatever extra concrete is available.

Thanks for the advice!

The driver was a hellofahand to work like that. Pours I’ve been on all the driver does is press the levers and wash down. Of course we always had more than one guy on hand...The deed is done!

The fellow who delivered the concrete was a big help - working the bull float looks likes it takes some finesse.

We had to extend the extension another 6’ or so to take all the extra concrete. Thanks agai forane! 4 yards altogether got the job done.

Thanks again for all the help!

Just one more suggestion if I may...don't gag your lolly in getting it back filled. The worse thing that can happen now is to have rain runoff undercut it by washing some of the gravel out from under it.

Re-establishing proper sub grade compaction if this happens is damned near impossible.

Angle of repose. The aggregate by itself will not “flow” until its angle of repose is exceeded. The angle can be viewed/measured at any sand pile. Add in a properly dry mix (google slump test) and you see how the properties of a cement slurry can be tailored to avoid problems with flow. Throw in some CaCl and the slurry will set quickly. Do not throw in sugar by mistake...Very cool project.

So I have an extremely dumb question but there seem to be a number of concrete experts here, so here goes.

How in the world do they pour steeply sloped driveways and pads? I’ve always wondered that my entire life, honestly.

I always figured they make it very dense but doesn’t it still want to run downhill like a very slow mudslide?

I’m not talking steep enough that they terrace it in multiple pours, but steep enough you’d think it would all run downhill somehow before it set.

Looks great Eddie! When does the steel building get set on it?

Eddie--Got back up to the property Monday, and knocked off the forms yesterday and hacked out the tiedown rings - photos to follow.

Looking good, but...

All of the sides of the slab look nice and solid - except the back, which has gaps. I think the word is “honeycombed”. Even though I was tamping down with a hard rake, I recall that right after the pour started the driver suggested he needed to add some water to the mix. Hence, that very first pass might have been a tad “dry”.

Question: is it worth my while to fill it in before backfilling? If I don’t it sure seems water could intrude and freeze, causing problems. And if I do, what should I trowel in there? I have a partial bag of Quickcrete I could mix up, but some sort of premix from a bucket or even a caulking gun would be less of a chore.

Thanks yet again in advance!

Yamaha TW200?

We had a bunch of those at the motorcycle training school I taught at a few years back. Almost indestructible fun little machines.Yep!

My KTM 950 Adventure was just starting to feel too intimidating, so about 6 months ago I sold it and bought the 2017 “TDub”.

Which is an absolute hoot, both on an off-road.

Wringing every last ounce of performance from 196cc and 16hp is a whole new challenge!

Earning my “Dragon” about a month ago:

Drop by our TN digs and let’s ride!

Very cool project.

So I have an extremely dumb question but there seem to be a number of concrete experts here, so here goes.

How in the world do they pour steeply sloped driveways and pads? I’ve always wondered that my entire life, honestly.

I always figured they make it very dense but doesn’t it still want to run downhill like a very slow mudslide?

I’m not talking steep enough that they terrace it in multiple pours, but steep enough you’d think it would all run downhill somehow before it set.

Drop by our TN digs and let’s ride!